Series 642 INSTALLATION

813316EB Edition 2017-11-24 19/

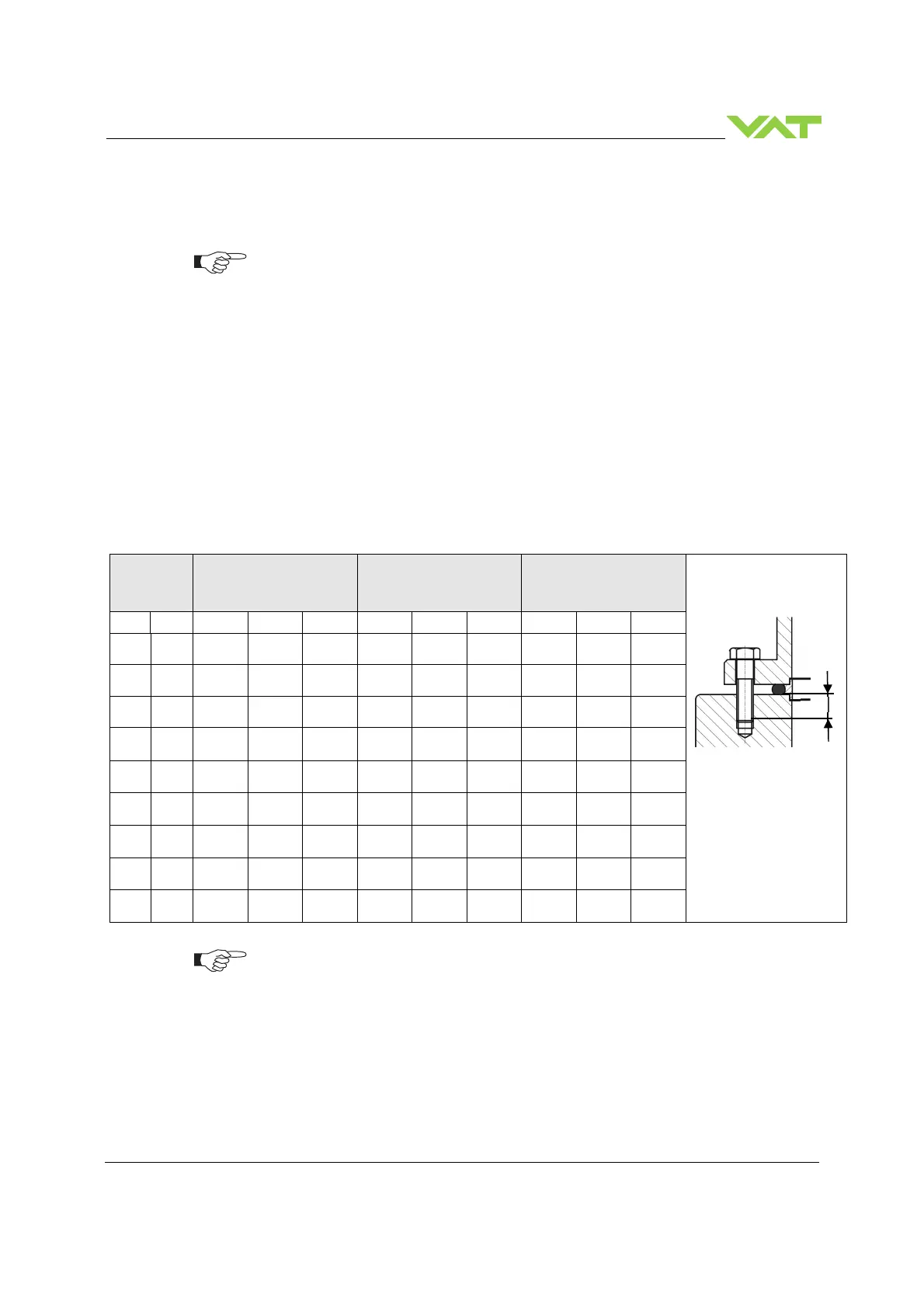

4.3 Tightening torque

Tighten mounting screws of the flanges uniformly in crosswise order. Observe the maximum torque

levels in the following tables.

4.3.1 Mounting with centering rings

DN

max. torque

(Nm)

max. torque

(lbs . ft)

Max. hole depth [d]

(mm)

mm inch ISO-F JIS ASA-LP

ISO-F JIS ASA-LP

ISO-F JIS ASA-LP

63 2 1/2 8 – 10 8 – 10 8 – 10 6 – 8 6 – 8 6 – 8 13 13 15

80 3 8 – 10 8 – 10 8 – 10 6 – 8 6 – 8 6 – 8 13 13 15

100 4 8 – 10 8 – 10 8 – 10 6 – 8 6 – 8 6 – 8 13 13 15

160 6 13 – 15 13 – 15 20 - 30 9 - 11 9 - 11 15 – 22 14 14 15

200 8 13 – 15 13 – 15 20 - 30 9 - 11 9 - 11 15 – 22 16 16 20

250 10 17 – 20 17 – 20 40 – 60 13 – 15 13–15 30 – 44 16 16 20

320 12 17 - 20 17 – 20 40 - 60 13 – 15 13–15 30 - 44 16 16 20

350 12 17 - 20 17 – 20 40 - 60 13 – 15 13–15 30 - 44 16 16 20

400 16 17 – 20 30 – 35 55 – 80 13 – 15 22 – 26 41 – 59 25 25 NA

The torque values below are dependent on many factors, such as materials involved,

surface quality, surface treatment, and lubrication.

The torques below are valid if immersion depth of the mounting screws is at least

once the thread diameter (min. 1d), and the friction coefficient of the screw-flange

connection (µ

total

= (µ

screw thread-helicoil

+ µ

under screw head

)/2) is bigger than 0.12. Lower

friction coefficients may damage the valve, as the resulting preload force gets too

high. Therefore for other friction coefficients the torque needs to be adapted. Please

review design guidelines for Helicoil-Screw connections and make sure that screws in

use are capable to withstand applied torques, are appropriate for the application and

are not too long. Too long screws may damage the valve, the immersion depth should

Refer to «Spare parts / Accessories» for centering rings ordering numbers.

Loading...

Loading...