Series 642 INSTALLATION

813316EB Edition 2017-11-24 37/

4.6 Initial operation

4.6.1 Setup procedure

To enable the valve for

setup steps

.

In case position control is required only it’s sufficient to perform steps 1 to 5.

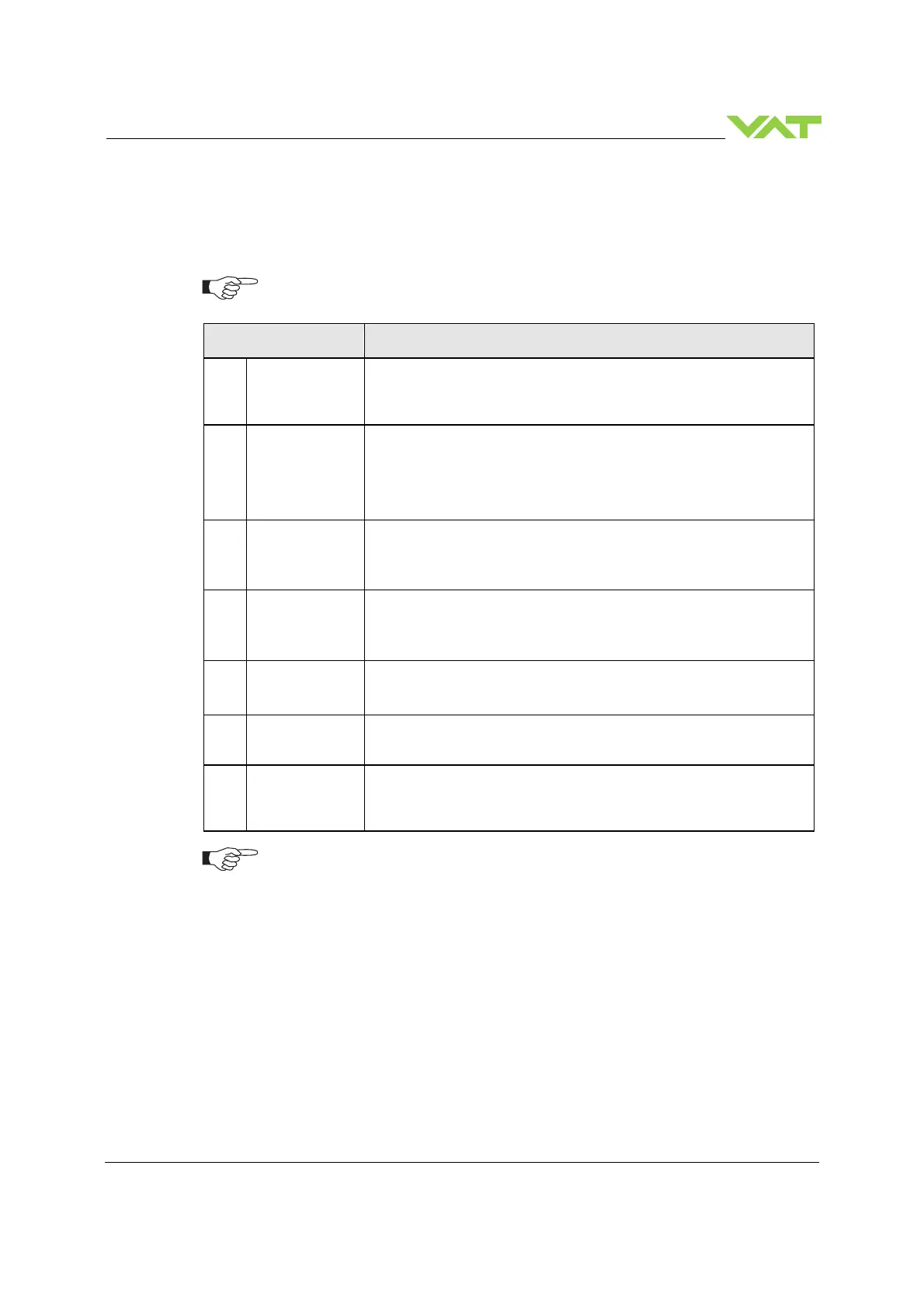

Setup step Description

1

Power up

Turn on external + 24VDC power supply (and external ±15 VDC for

sensor power supply if required). Refer to chapter «Behavior during

power up» for details.

2

CC-Link

configuration

1. Station Number

2. Transmission rate

3. Operational settings mode

Refer to chapter «CC-Link configuration» for details.

3

Valve

configuration

Basic configurations of the valve must be adapted according to

application needs.

Refer to chapter «Valve configuration» for details.

4

Sensor

configuration

Basic configurations of the valve must be adapted according to

application needs.

Refer to chapter «Sensor configuration» for details.

5

ZERO

Compensation of the sensor offset voltage.

Refer to chapter «ZERO» for details.

6a

LEARN

Determination of the vacuum system characteristic to accommodate the

PID controller. Refer to chapter «LEARN adaptive» for details.

6b

PRESSURE

CONTROL

COFIGURATION

Accommodation of PID controller to the vacuum system characteristic.

Refer to chapter: «Pressure Control configuration» for details.

Without «LEARN adaptive» or «Pressure Control configuration» the valve is not

able to run pressure control.

•

For ease setup (in Local mode) of ‘Interface’, ‘Valve’, ‘Sensor’, ‘Senor ZERO’,

‘LEARN’ and ‘PRESSURE CONTROL COFIGURATION’ it is possible to use the

CPA 3.0, The free download is available on the VAT homepage:

http://www.vatvalve.com/customer-service/informations-and-downloads/control-

performance-analyzer

Loading...

Loading...