Module MK40 Setup Manual

ВШПА.421412.304 И1

CAN2.0B

interface

CAN2.0B interface provides for possibility of MK40 Module status data transfer to indicating units and statistics

gathering module. MK40Module does not receive any data via CAN2.0B interface, possibility of module setup by

means of CAN2.0B interface is not provided either.

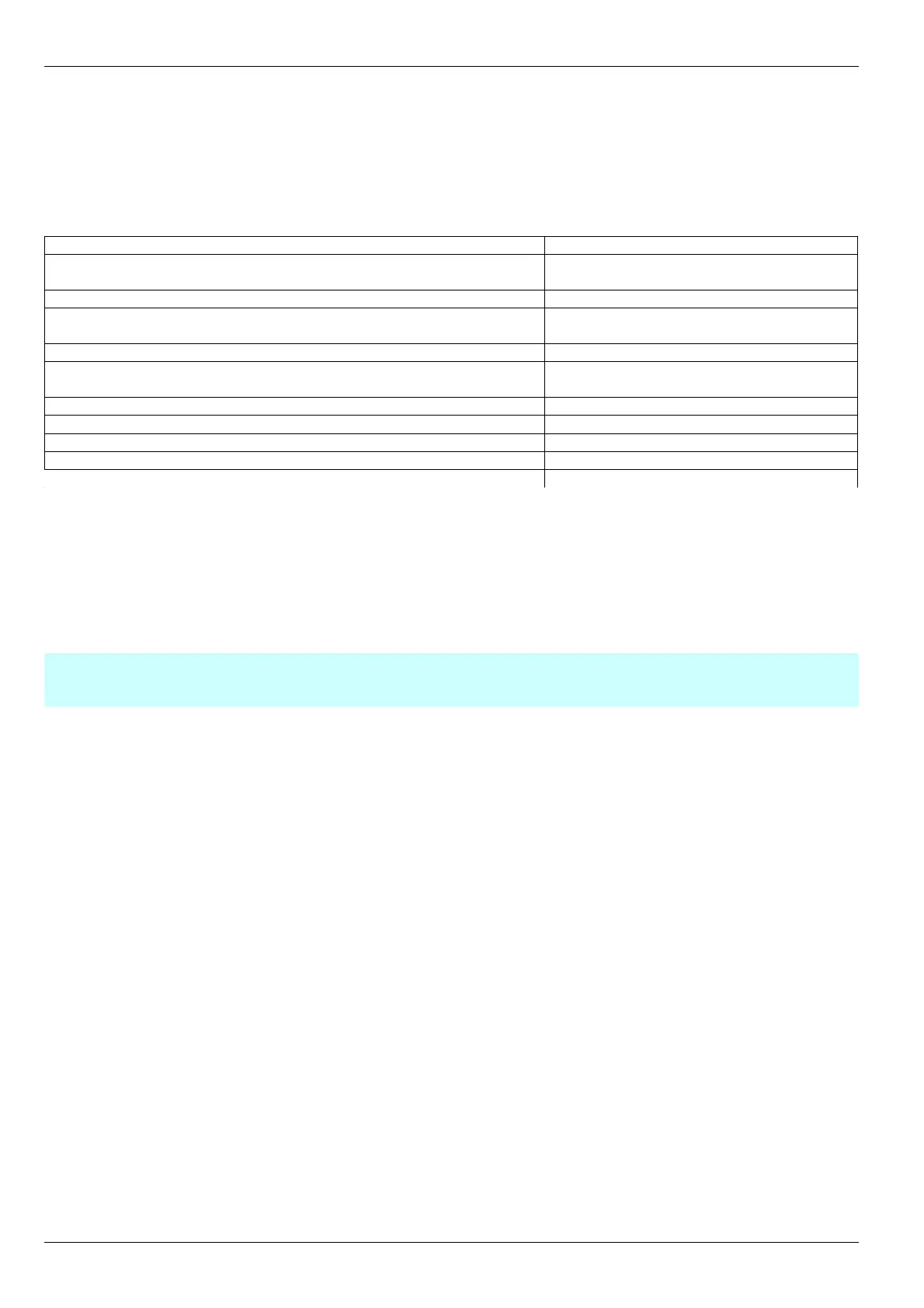

Table 11. CAN2.0B interface parameters

Parameter name Value

Operating mode data transfer in active mode with possibility

of bus reset generation

Message format only extended

Exchange protocol unified for operation as part of “VIBROBIT

300” equipment set

MK40 Module indicating units code 0xC4 (196)

Data rate (one of speed values is setup), Kbit/c 1000; 500; 250; 200;

125; 100; 80; 40

CAN bus standards compliance ISO-11898

(1)

Maximum number of bus cross-points 112

(1)

Driver input resistance, kOhm, not less than 5

(1)

Electrical endurance, kV, not less than ±6

(1)

Galvanic isolation no

(1)

Note 1.On condition that MCP2551 driver is used.

Module CAN controller operates in active mode, i.e. generates dominant acknowledgement of received data

and can generate active reset message to CAN bus (for example, in case of incorrect indication of data rate)

All CAN bus cross-points must have equal data rate. At increase of data rate, CAN bus physical maximum light

decreases. CAN bus maximum allowed length at 1000Kbit/s data rate is 40 meters, and at 40Kbit/s data rate – 1000

meters.

Note. CAN2.0B bus terminator is provided on MK40 Module board. If the module is last to be connected to

RS485 bus and standard 120 Ohm bus terminator is missing, bridge with bus terminator must be installed on the

module board for normal operation of RS485 interface.

The following parameters must be set up for CAN2.0B interface operation.

•

CAN2.0B operation enabling (CanEnabled);

•

Data rate (CanSpeed);

•

Module address (CanBasicAddress);

•

Message transfer intervals (CanBasicTime);

•

Data transfer enabling via measuring channels (CanBasicDataOut).

Measuring results data are transferred with CanBasicDataOut intervals. Individual message with unique

message code is generated or each of measuring channels:

0x30(48) – 1

st

measuring channel message;

0x31(49) – 2

nd

measuring channel message.

0x32(50) – Combined message. In normal state, message with 1

st

channel measurement result is transferred. In

case of 1

st

channel fault, message 2

nd

channel measurement is transferred. In case of both channels fault, message is

not transferred (implemented in module software version 3.40 and newer).

Messages are transferred sequentially: 1

st

measuring channel messages, then – 2ng measuring channel

messages. New message is not transferred to bus, until previous message is transferred. If current message is not

sent within 200ms, sending is cancelled.

24

No revisions

Loading...

Loading...