ВШПА.421412.304 И1 SCIENTIFIC-PRODUCTION ENTERPRISE VIBROBIT LLC

Comparing measured parameter value with set-point value

If FlagError flag is dropped (wait timeout is counted after sensor operation normalization), calculated rotor

speed value of is compared with set-points values, set during the module setup.

If sensor fault has been detected (one of ErrorSenseLow, ErrorSenseHigh flags is activated) or

FlagError flag is activated, comparison of calculated D

Param

value with set-points values is not implemented, and all

measured parameter value overrun flags are dropped.

Four set-points are provided for each measuring channel (TestPointData) with individually setup operating

modes (TestPointMode), general hysteresis level (TestPointHist) and overrun response time

(TestPointTime).

Table 3. Set-points operating modes

Mode code Description

0 Set-point is disabled, test is not carried out

1 Test above set-point value

2 Test below set-point value

Operating mode – set-points are disabled

Rotor speed value is not compared with TestPointData set-point, OutPoint flag is always dropped.

Operating mode - test above set-point value

If rotor speed value is higher than TestPointData set-point within TestPointTime time, parameter level is deemed

too high and OutPoint flag is activated. In order to drop OutPoint flag (normal level), rotor speed value must be lower

that TestPointData-TestPointHist within TestPointTime time.

Operating mode - test below set-point value

If rotor speed value is lower than TestPointData set-point value within TestPointTime time, parameter level is

deemed too low and OutPoint flag is activated. In order to drop OutPoint flag (normal level), rotor speed value must be

higher that TestPointData+TestPointHist within TestPointTime time.

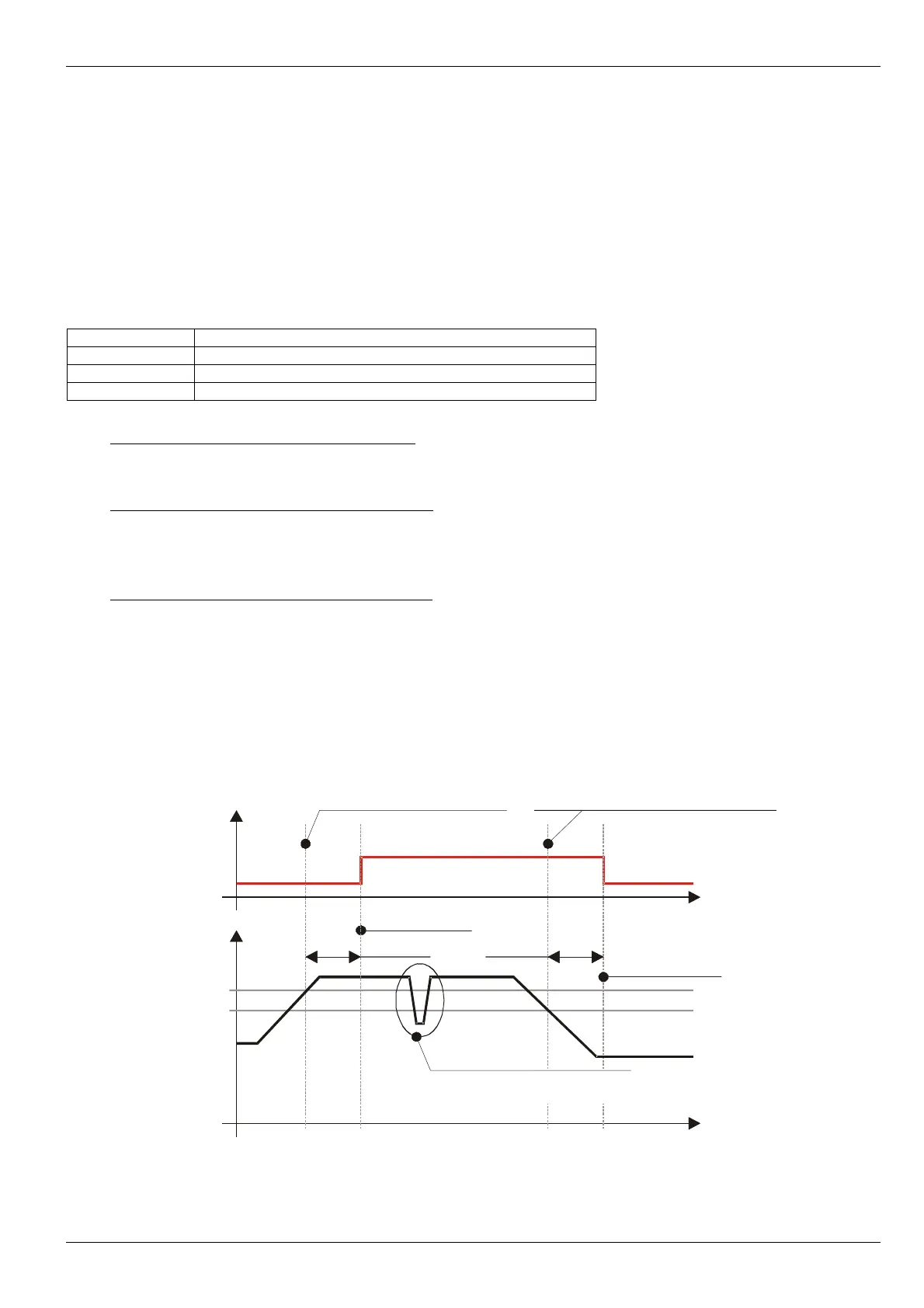

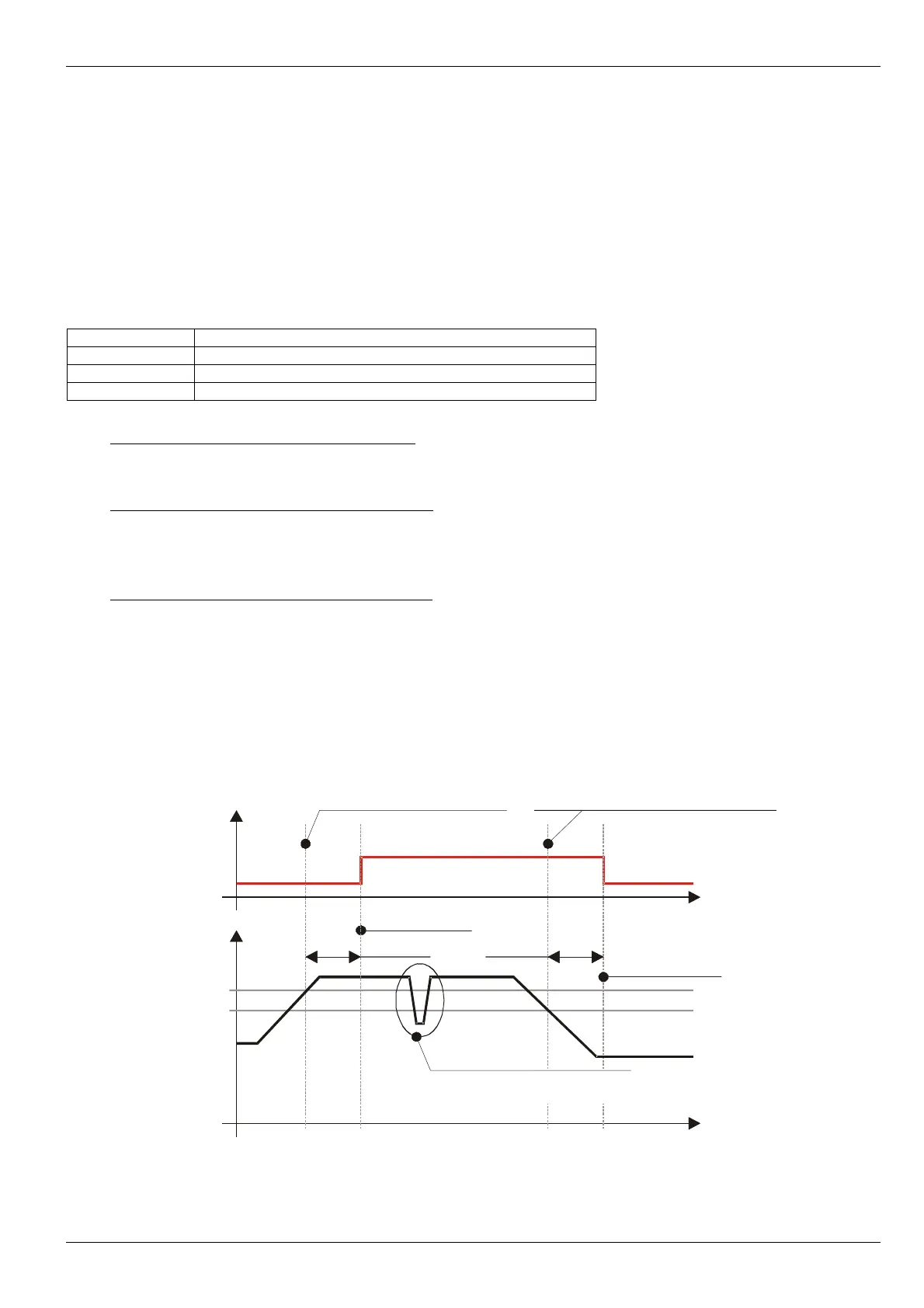

Figure 5 shows an example of alarm function at set-point 2400rpm and hysteresis of 100prm.

Set-points test enabling in “STOP” mode is determined by StopEnabled parameter. If StopEnabled parameter is

equal to zero, in “STOP” mode rotor speed value (equal to 0) is not compared with set-points, rotor speed overrun

flags are inactive.

Figure 5. Example of set-point algorithm

(mode – test above set-point level).

No revisions

15

OutPoint

Time TestPointTime

Flag

Logic

level

Detected output value of

the parameter for set point

Value of parameter is less set

point taking into account a hysteresis

Time

Time

Signaling switching-on

Signaling switching-off

Short-term surge doesn't

cause signaling switching

Freq, rpm

2400

2500

Loading...

Loading...