ВШПА.421412.304 И1 SCIENTIFIC-PRODUCTION ENTERPRISE VIBROBIT LLC

MK40-DC-001

design option

MK40 Module front panel is provided with customized alphanumeric LCD, signal LED’s and control keys. All

measuring channel measurement results and measuring channels state can be displayed simultaneously.

On the module front panel are arranged:

•

Customized alphanumeric LCD with backlight;

•

Signal LED’s”

•

“Pwr” green LED – module switching on;

•

“Ok” bicolor LED – module status indication;

•

“War” yellow LED – warning (LED operation logic is defined by user);

•

“Alarm” red LED – alarm (operation logic is defined by user);

Two control keys

•

“Mode” key – display mode selection

•

“Sel” key – displayed data selection

Controlled parameter overrun of set-point is signaled by “V1”, “V2”, “V3” and “V4” symbols

(in frame).

“Er” (in frame) symbol indicates sensor fault detected in actual measuring channel;

measured parameter value is deemed equal to zero (lines are displayed on LCD), actual

measuring channels set-points alarm is inactive.

After measuring channel operation is normalized, “Er” symbol starts flashing, and the unit

counts measuring channel normalization timeout (set by user).

In “STOP” mode rotor speed value is deemed equal to zero, nonsignificant decimal point

is displayed after “0” symbol At “STOP” alarm testing, nonsignificant decimal point, following

rotor speed value, starts flashing.

At test signal connection to measuring channel input, empty frame of non-existing set-point 4 starts flashing on

top right panel of measuring channel data display.

In supply voltage measuring mode of 2

nd

measuring channel, actual supply voltage of the module is displayed

on bottom panel of measuring channel data display, while standard 2

nd

measuring channel data is not displayed.

In order to display maximum rotor speed, press “Mode” key until rotor speed value appears on LCD (in two

channels simultaneously). During maximum rotor speed displaying, measuring unit symbols “rpm” start flashing on

LCD, while symbols of measured parameter value overrun of set-point are not displayed. Return to normal display

mode is implemented by repeated pressing of “Mode” key or automatically upon timeout.

In order to display sensors direct current, press and hold down “Mode” key, until sensor current value appears

on LCD (in two channels simultaneously). During sensor current display, measuring unit symbols “mA” appear on LCD,

while symbols of measured parameter value overrun of set-point are not displayed. Return to normal display mode is

implemented by repeated pressing and holding down of “Mode” key or automatically upon timeout.

For set-points values displaying on LCD, press and hold down “Sel” key, until 1

st

measuring channel sign K1

and first set-point symbol V1 start flashing. By repeated (and short-term) pressing of “Sel” key, all three set-points of

actual measuring channel can be reviewed. Set-points values are displayed instead of measurement results. If set-

point is disabled (in module settings), lines are displayed instead of set-point.

Review of other measuring channel set-points values can be implemented by pressing “Sel” key or

automatically upon timeout.

Logic outputs on and off switching is implemented by simultaneous pressing and holding down of “Mode-Sel”

keys, until logic outputs operation mode is switched. When logic outputs are disabled, “Ok” LED glows yellow, and all

logic outputs are inactive.

No revisions

9

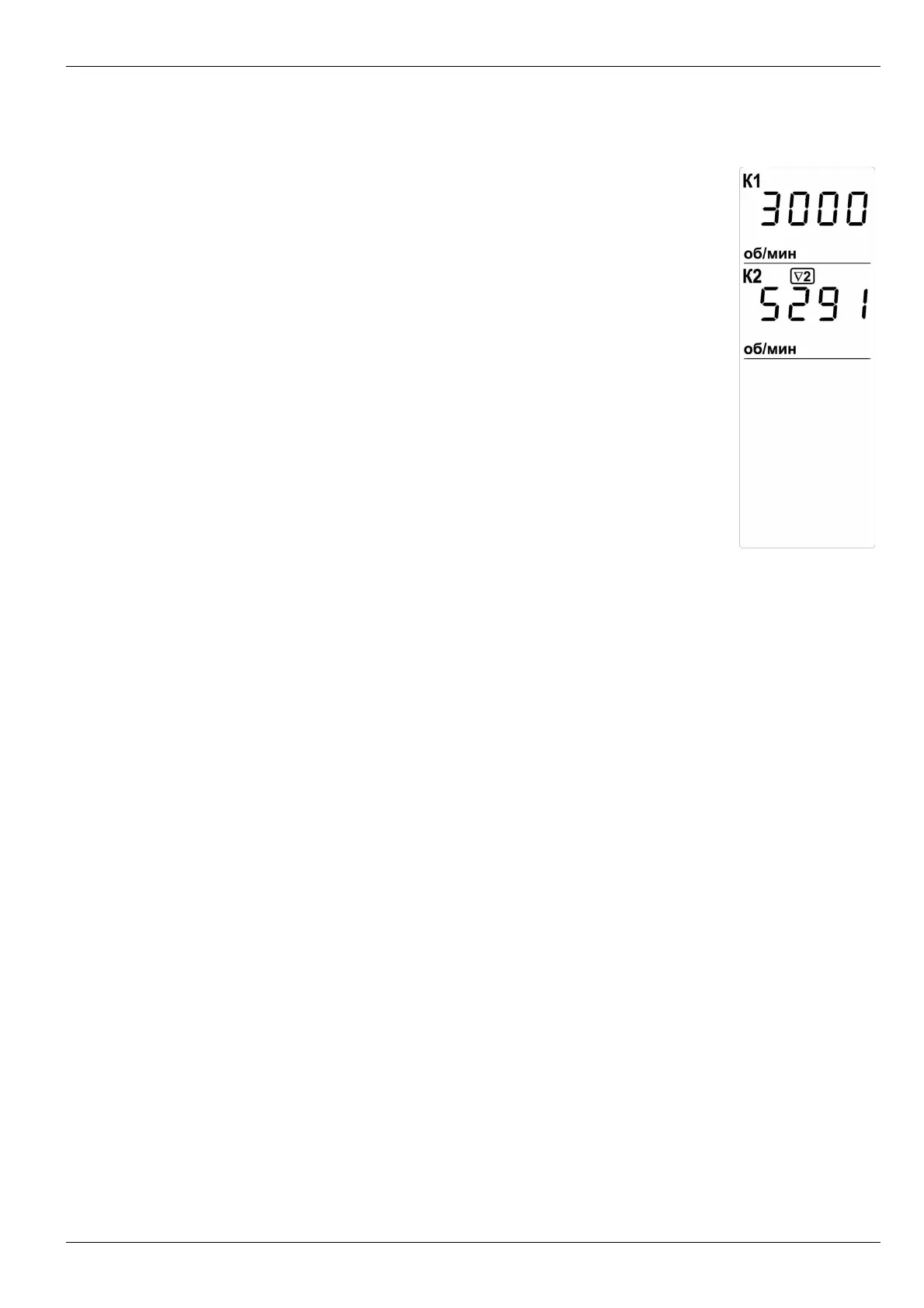

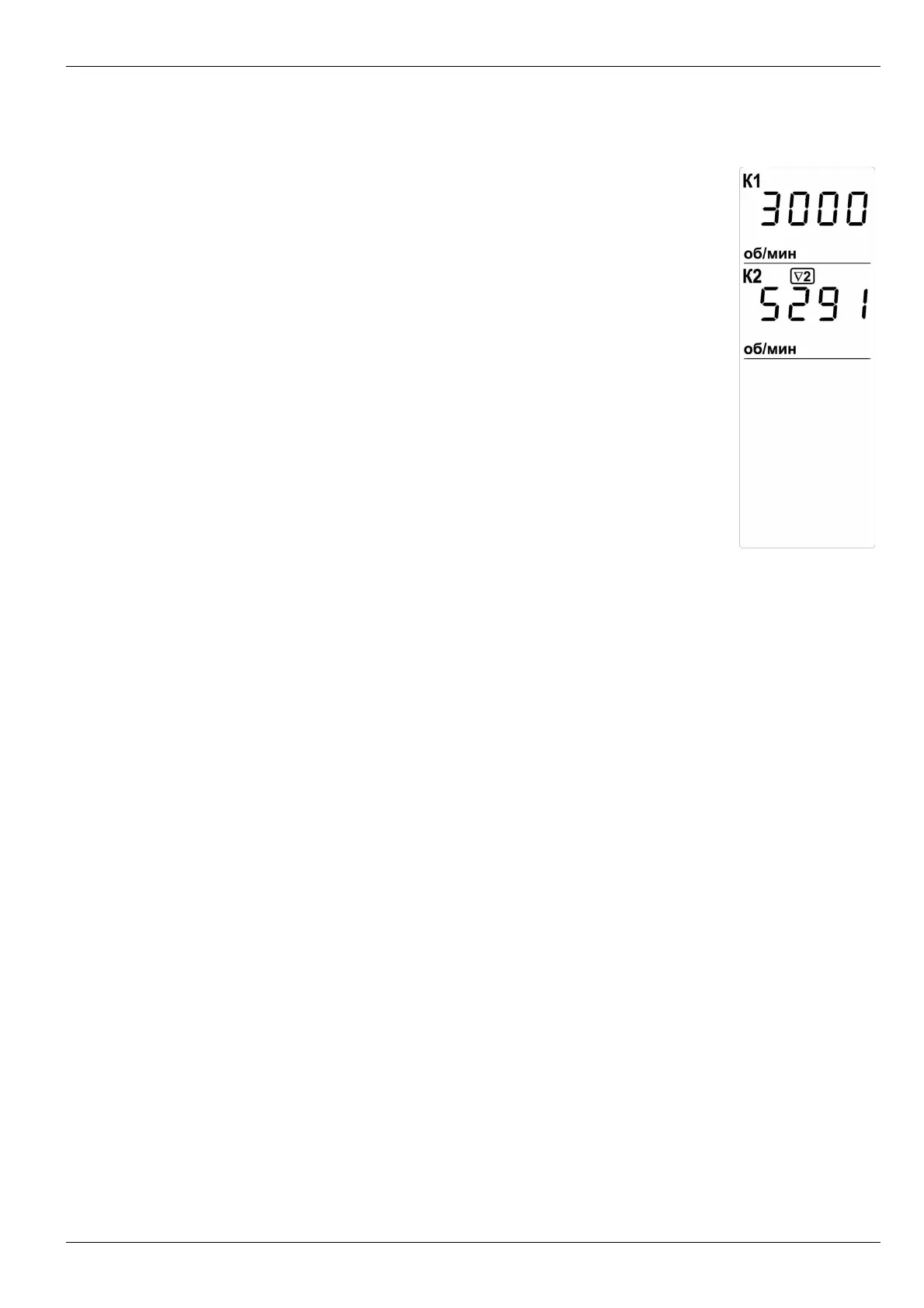

Figure 2. LCD data

display example

Loading...

Loading...