Reassembly Procedures WM 130/170/270 Repair

wc_tx000379gb.fm 52

9. Reassembly Procedures

9.1 Notes on Reassembly

Observe the following prior to/during reassembly of the engine:

• Clean each part carefully, taking special care with the piston, cylinder,

crankshaft, connecting rod, and bearings.

• Scrape off any carbon deposits on the cylinder head and the piston

head. Be particularly careful when removing carbon from the piston

ring grooves.

• Inspect oil seals for any damage to the lip. Replace them if damaged.

Apply oil to lip before re-assembling.

• Replace all gaskets with new ones.

• Replace keys, pins, bolts and nuts with new ones if necessary.

• Tighten nuts and bolts to the specified torque settings.

• During re-assembly, apply oil to all moving parts.

• Check clearances and end plays. Adjust the clearances as necessary.

• When mounting any major moving part, rotate it with your hand to

check for any jamming or abnormal noise.

9.2 Oil Sensor

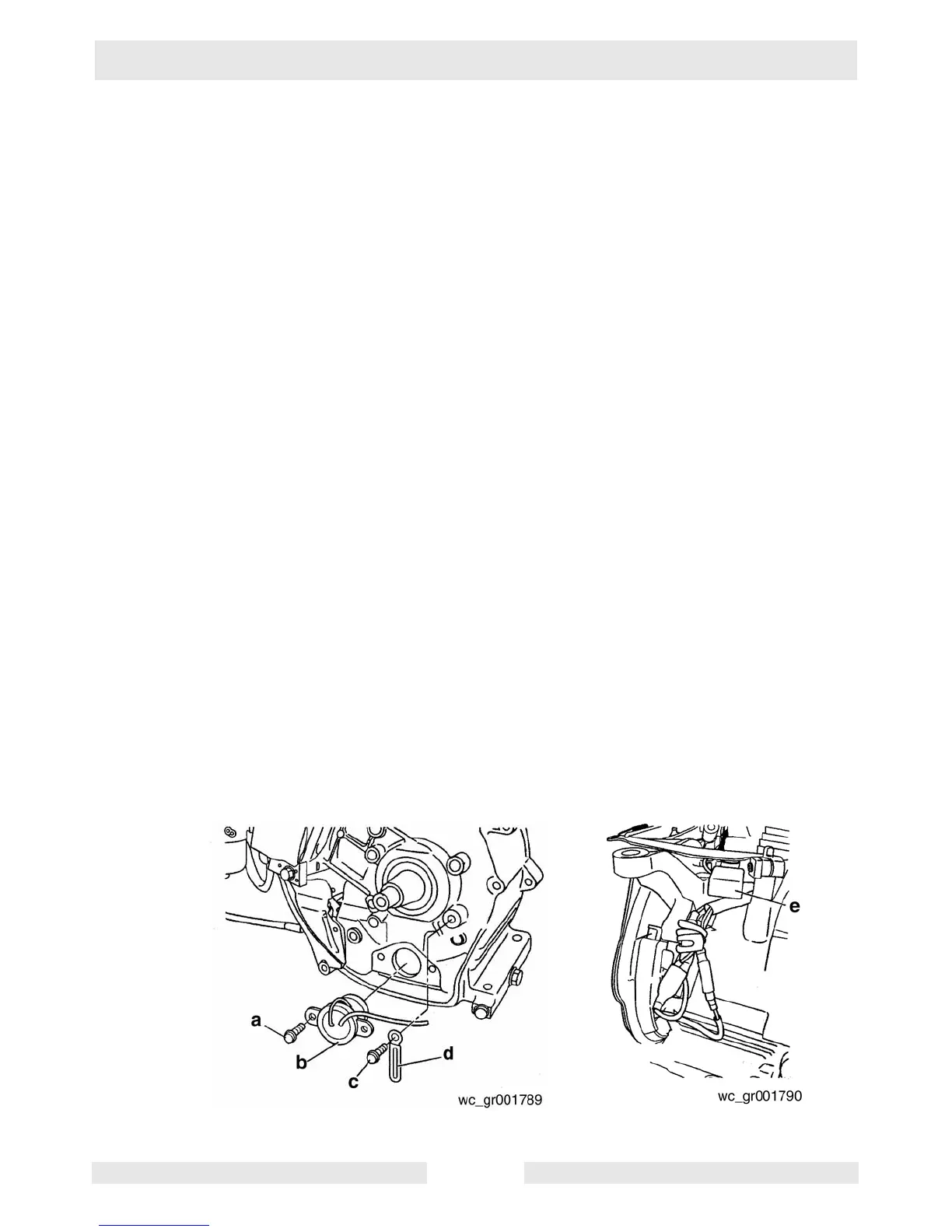

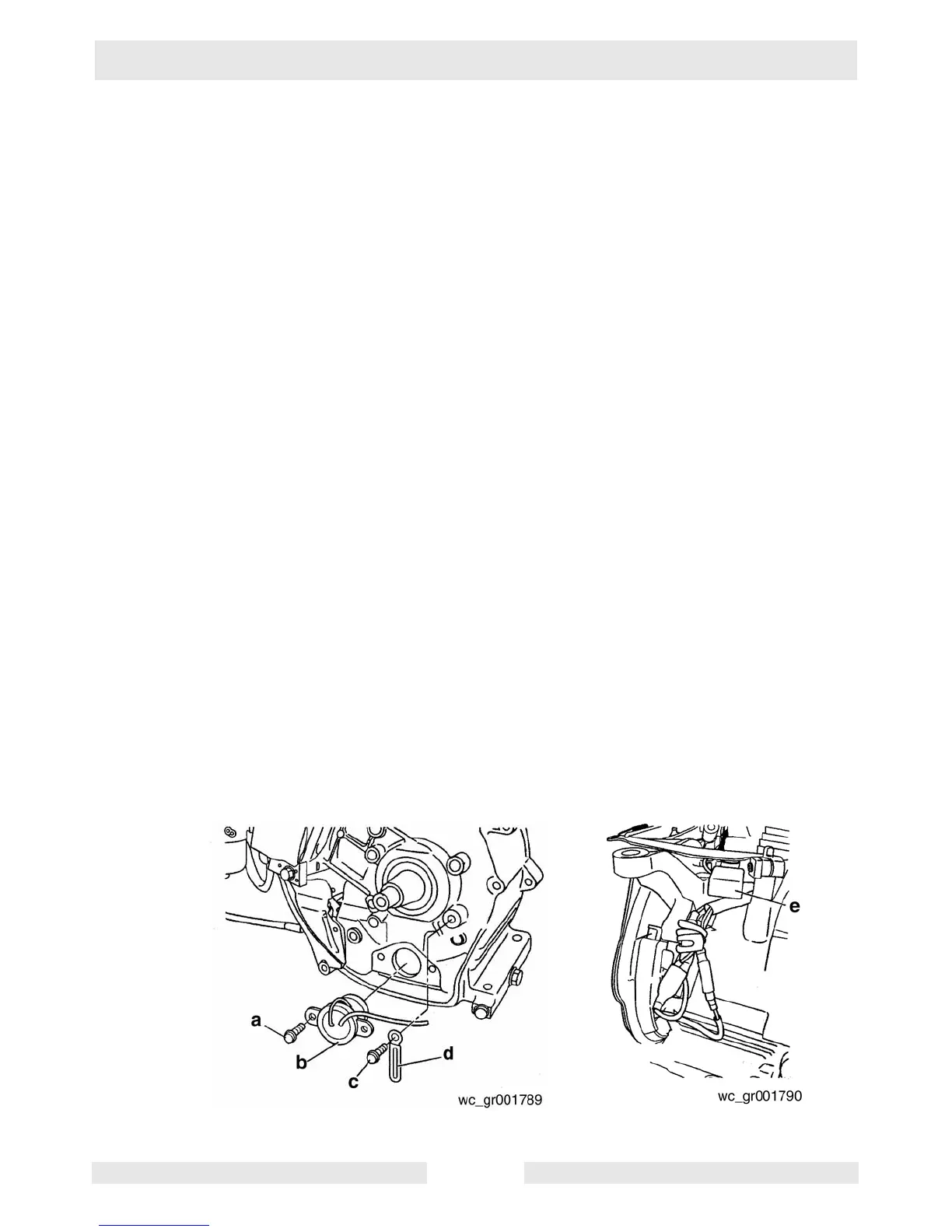

See Graphic: wc_gr001789 and wc_gr001790

9.2.1 Using M6x16 screws (a), mount the oil sensor (b).

9.2.2 Using M6x12 screw (c), secure the wire with the clamp (d).

9.2.3 Mount the control unit (e) and the ground wire.

Loading...

Loading...