WM 130/170/270 Repair Reassembly Procedures

wc_tx000379gb.fm 67

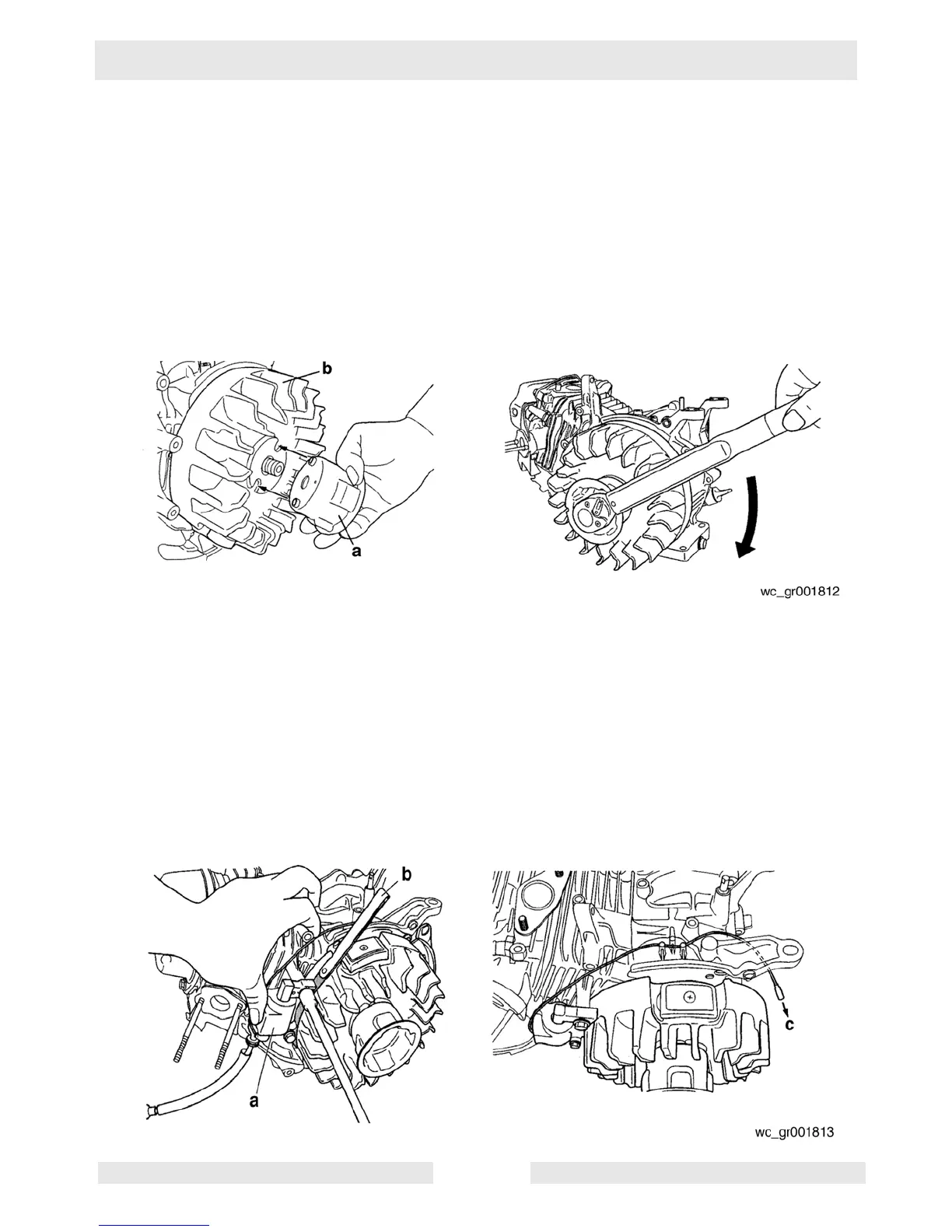

9.18 Flywheel and Starter Pulley

See Graphic: wc_gr001812

Note: When mounting the flywheel, be sure to wipe off any oil on the

tapered portion of the crankshaft and flywheel.

9.18.1 Place the flywheel on the crankshaft. Align the two bosses of the

starter pulley (a) with the two depressions on the flywheel (b).

9.18.2 Tighten the flywheel together with the starter pulley. Torque the nut to

59.0–64.0 Nm (42.7–46.3 ft.lbs).

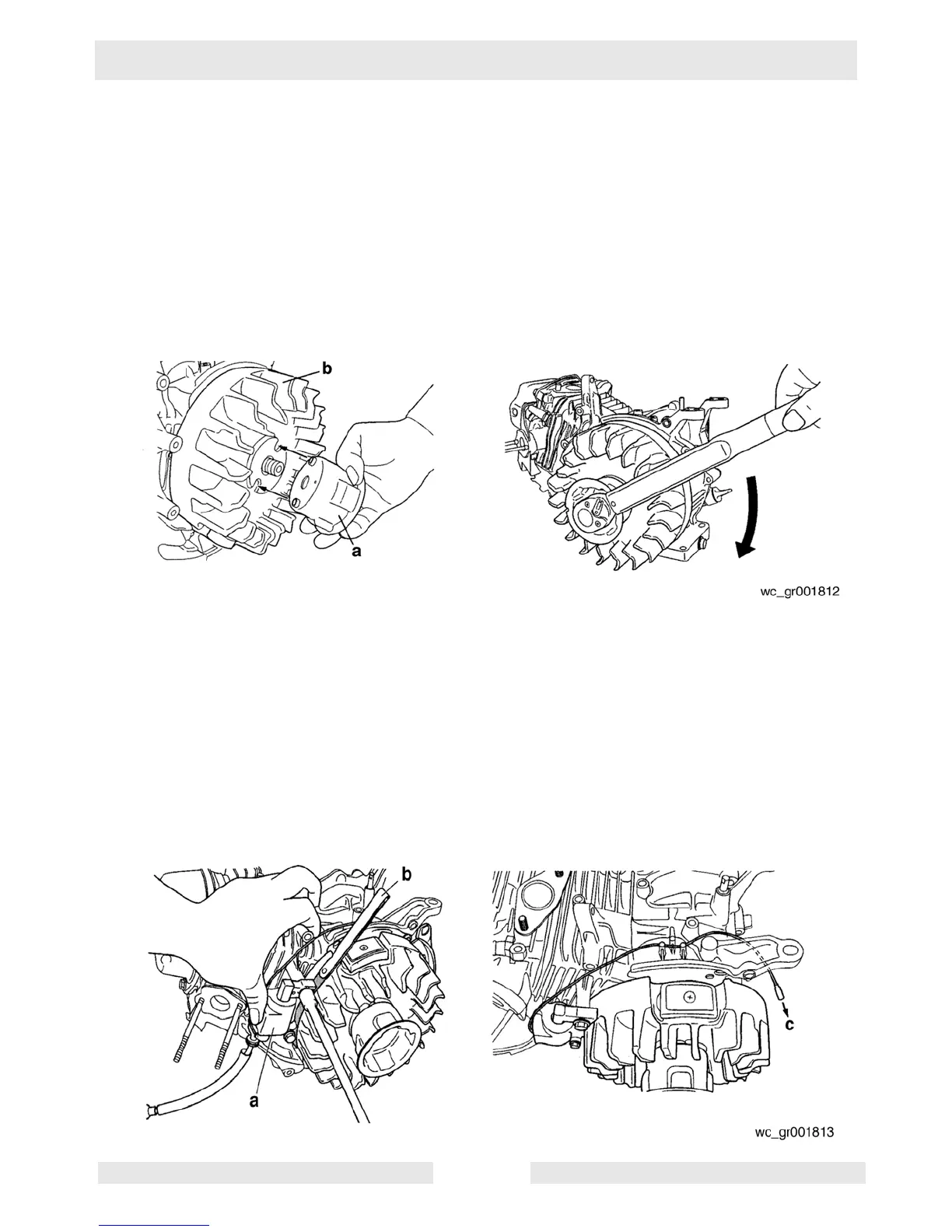

9.19 Ignition Coil

See Graphic: wc_gr001813

9.19.1 Using two M6 x 25 bolts and washers, secure the ignition coil (a) to the

engine. Use a thickness gauge (b) to set the air gap of 0.3–0.5 mm

(0.011–0.019 in.).

Torque the nuts to 7.0–9.0 Nm (5.1–6.5 ft.lbs.).

Reference: Wire to stop switch (c).

Loading...

Loading...