4Maintenance Procedures

40 July 7, 2014, 715003736IVD Rev. C

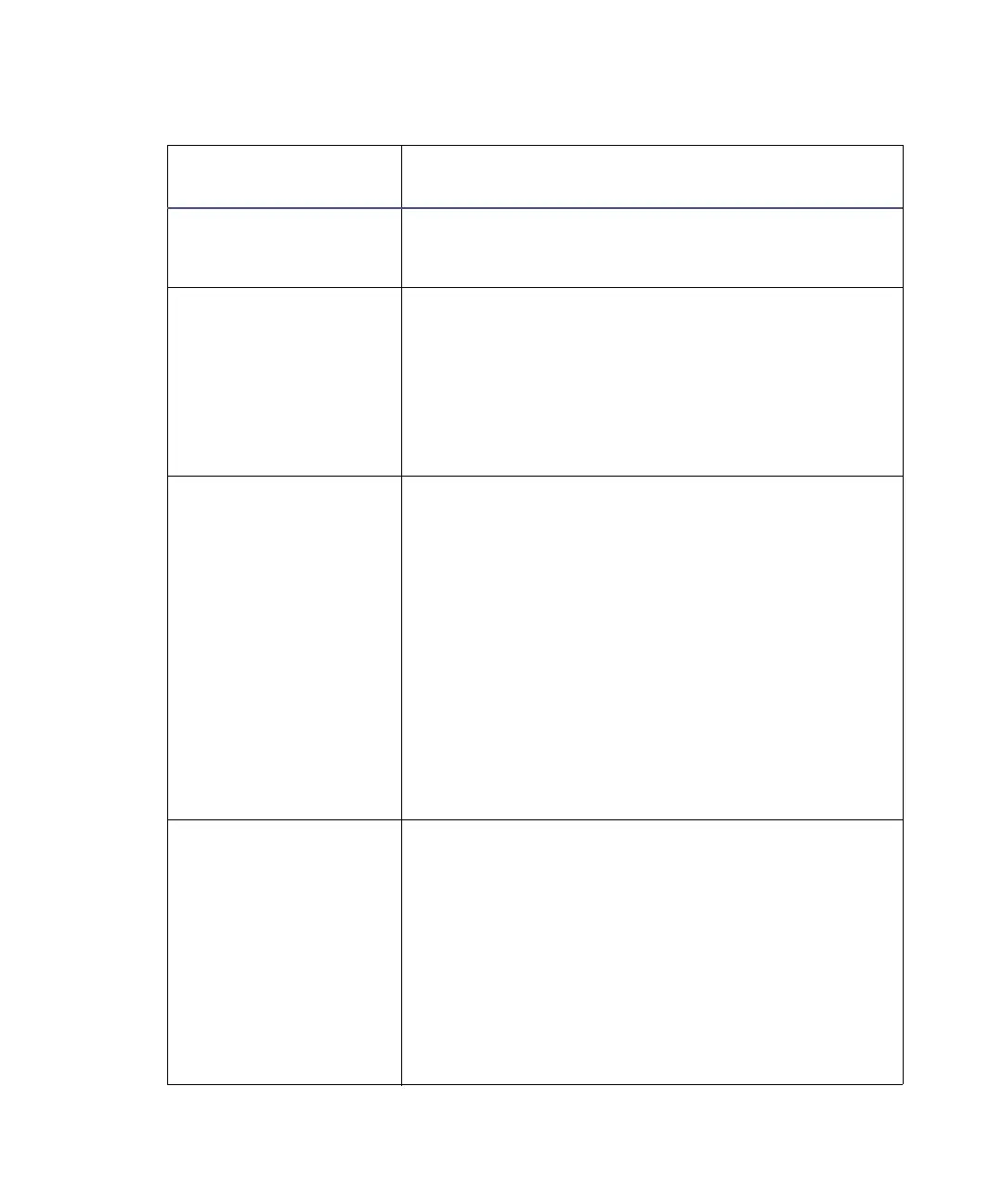

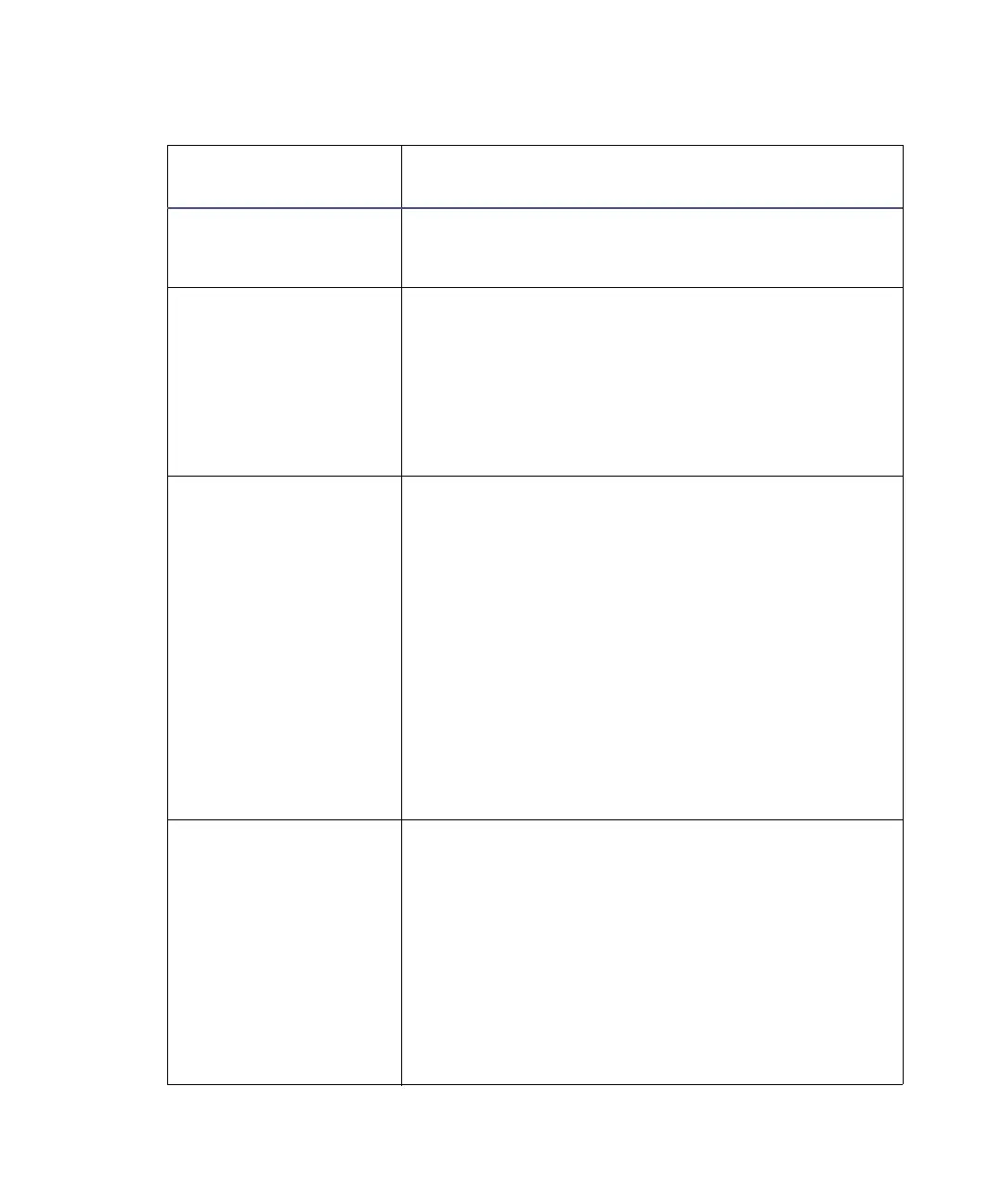

Column Manager maintenance procedures:

Maintenance

procedure

Frequency

Replace the leak

sensor on the column

heater

As needed. For example, when the leak sensor is

damaged or an error message states the leak sensor

is not detected.

Replace the column As needed. The typical failure modes are as follows:

•High backpressure. The column causes a high

pressure shutdown.

•Method requirements are not attained. This can

be exhibited by poor peak shape, resolution

between peaks lost, tailing, etc. Perform a plate

count to establish column efficiency.

Replace the active

preheater assembly

As needed. The typical failure modes are as follows:

•Error message. Any active preheater error

messages, including messages indicating the

active preheater is not detected or connected or

has a temperature sensor error.

•Leak. This can be detected visibly, using the leak

sensor or by noticing that peak retention times

vary.

•Carryover. Reseat the active preheater assembly

connections and/or replace the ferrules.

•Split peaks. Reseat the active preheater

assembly connections and/or replace the

ferrules.

Replace the column

stabilizer assembly

As needed. The typical failure modes are as follows:

•Leak. This can be detected visibly, using the leak

sensor or by noticing the peak retention times

vary.

•Carryover. Reseat the column stabilizer

assembly connections and/or replace the

ferrules.

•Split peaks. Reseat the column stabilizer

assembly connections and/or replace the

ferrules.

Loading...

Loading...