3-32 | CFW-11

NOTE!

In order to use the digital inputs as active low, remove the jumper between XC1:11 and 12 and

install it between XC1:12 and 13.

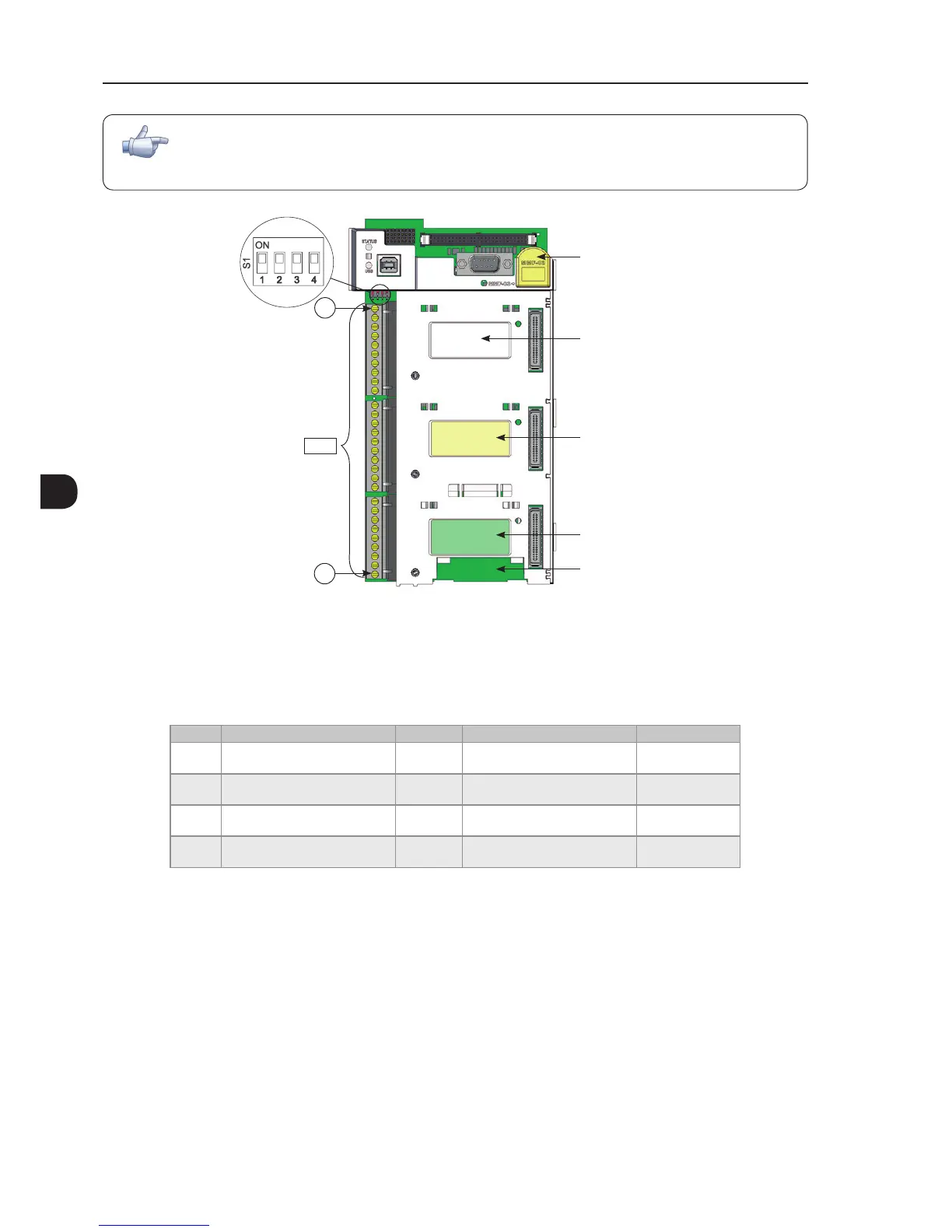

Slot 5

Slot 1 (white)

Slot 2 (yellow)

Slot 3 (green)

Slot 4

XC1

1

29

Figure 3.17 - XC1 terminal strip and DIP-switches for selecting the signal type of analog inputs and outputs

As the factory setting, the analog inputs and outputs are adjusted to operate in the 0 to 10 V range, but they

can be changed by using the S1 DIP-switch.

Table 3.7 - Conguration of DIP-switches for selecting the signal type of analog inputs and outputs

Signal Factory Setting Function DIP Switch Selection Factory Setting

AI1 Speed reference (remote) S1.4 OFF: 0 to 10 V (factory setting)

ON: 4 to 20 mA / 0 to 20 mA

OFF

AI2 No function S1.3 OFF: 0 to ±10 V (factory setting)

ON: 4 to 20 mA / 0 to 20 mA

OFF

AO1 Speed S1.1 OFF: 4 to 20 mA / 0 to 20 mA

ON: 0 to 10 V (factory setting)

ON

AO2 Motor current S1.2 OFF: 4 to 20 mA / 0 to 20 mA

ON: 0 to 10 V (factory setting)

ON

Parameters related to the analog inputs and outputs (AI1, AI2, AO1, and AO2) must be programmed according

to the DIP-switches settings and desired values.

Follow instructions below for the proper installation of the control wiring:

1. Wire gauge: 0.5 mm² (20 AWG) to 1.5 mm² (14 AWG).

2. Maximum tightening torque: 0.5 N.m (4.50 lbf.in).

3. Use shielded cables for the connections at XC1 and run the cables separated from the remaining circuits

(power, 110 V / 220 Vac control, etc.), as presented in Table 3.8 on page 3-34. If control cables must cross

other cables, it must be done perpendicularly among them, keeping a minimum of 5 cm (1.9 in) distance

at the crossing point.

Loading...

Loading...