earth leakage current depends on various system configurations including RFI filtering,

screened motor cables, and frequency converter power.

EN/EC61800–5–1 (Power Drive System Product standard) requires special care if the

leakage current exceeds 3.5 mA. Earth grounding must be reinforced in one of the

following ways:

• Earth ground wire of at least 8 AWG or 10 mm

2

Cu (or 16mm2 Al).

• Two separate earth ground wires of the same cross sectional area.

See EN60364–5–54 section 543.7 for further information.

On HYDROVAR, the phase conductor and the corresponding protective earthing

conductor can be of the same cross-sectional area, provided they are made of the same

metal (because the cross-sectional area of the phase conductor is less than 16 mm

2

).

The cross-sectional area of every protective earthing conductor which does not form a

part of the supply cable or cable enclosure shall, in any case, be not less than:

• 2.5 mm

2

if mechanical protection is provided or

• 4 mm

2

if mechanical protection is not provided. For cord-connected equipment,

provisions shall be made so that the protective earthing conductor in the cord shall, in

the case of failure of the strain-relief mechanism, be the last conductor to be

interrupted.

6.2 Protection devices

Fuses and Circuit Breakers

• An electronically activated function within the frequency converter provides overload

protection in the motor. The overload calculates the level of increase to activate timing

for the trip (controller output stop) function. The higher the current draw, the quicker

the trip response. The overload provides Class 20 motor protection. See Warnings and

alarms for details on the trip function.

• Hydrovar must be provided with short-circuit and over-current protection to avoid

overheating of the cables in the installation. Input fusing and/or circuit breakers are

required to provide this protection. Fuses and Circuit Breakers must be provided by

the installer as part of installations.

• Use recommended fuses and/or circuit breakers on the supply side as protection in

case of component breakdown inside the adjustable frequency drive (first fault). Use of

recommended fuses and circuit breakers ensures possible damage to the adjustable

frequency drive is limited to damages inside the unit. For other circuit breaker types,

ensure that the energy into the adjustable frequency drive is equal to or lower than the

energy provided by recommended types.

• The fuses below are suitable for use on a circuit capable of delivering 100,000 Ams

(symmetrical), 480V maximum. With the proper fusing the adjustable frequency drive

Short Circuit Current Rating (SCCR) is 100,000 Ams.

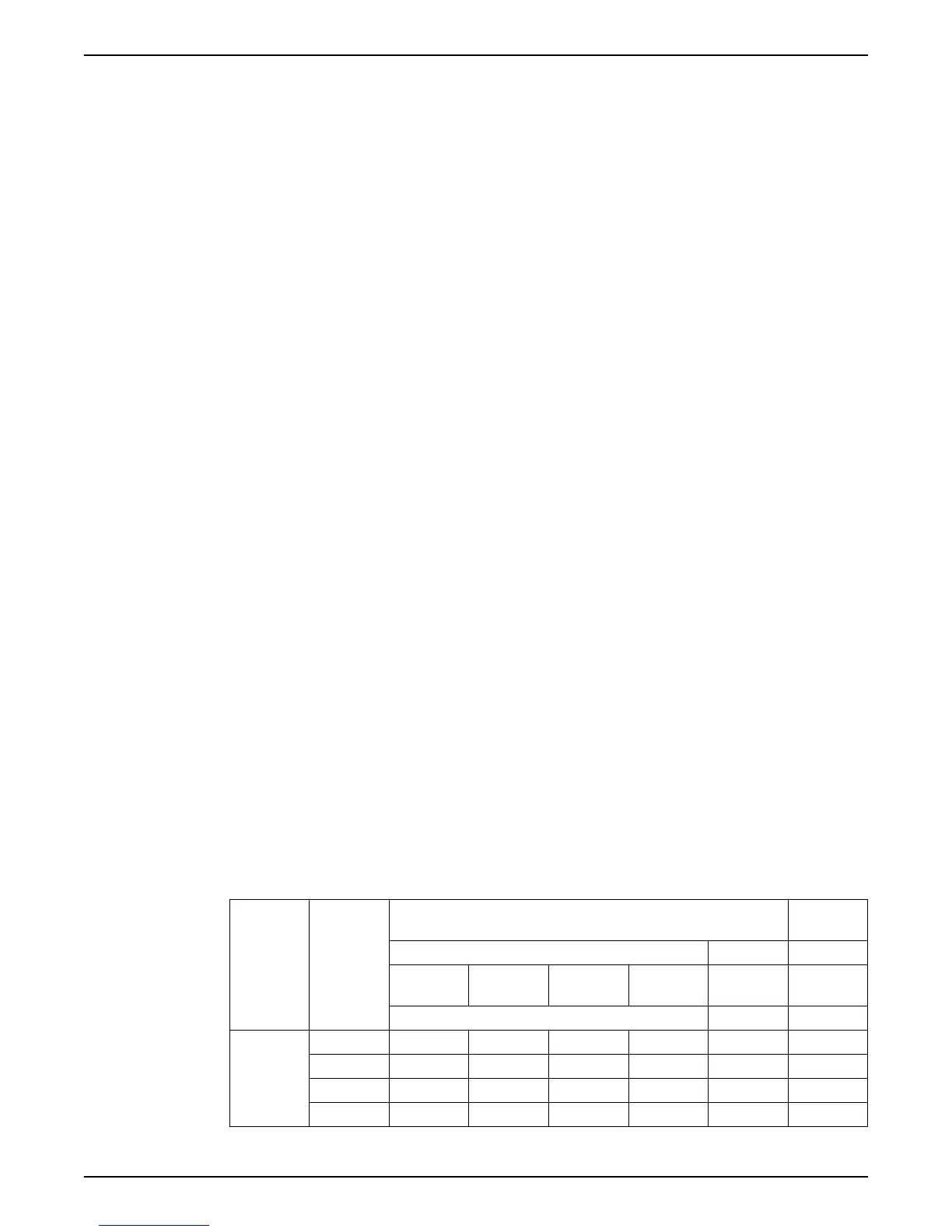

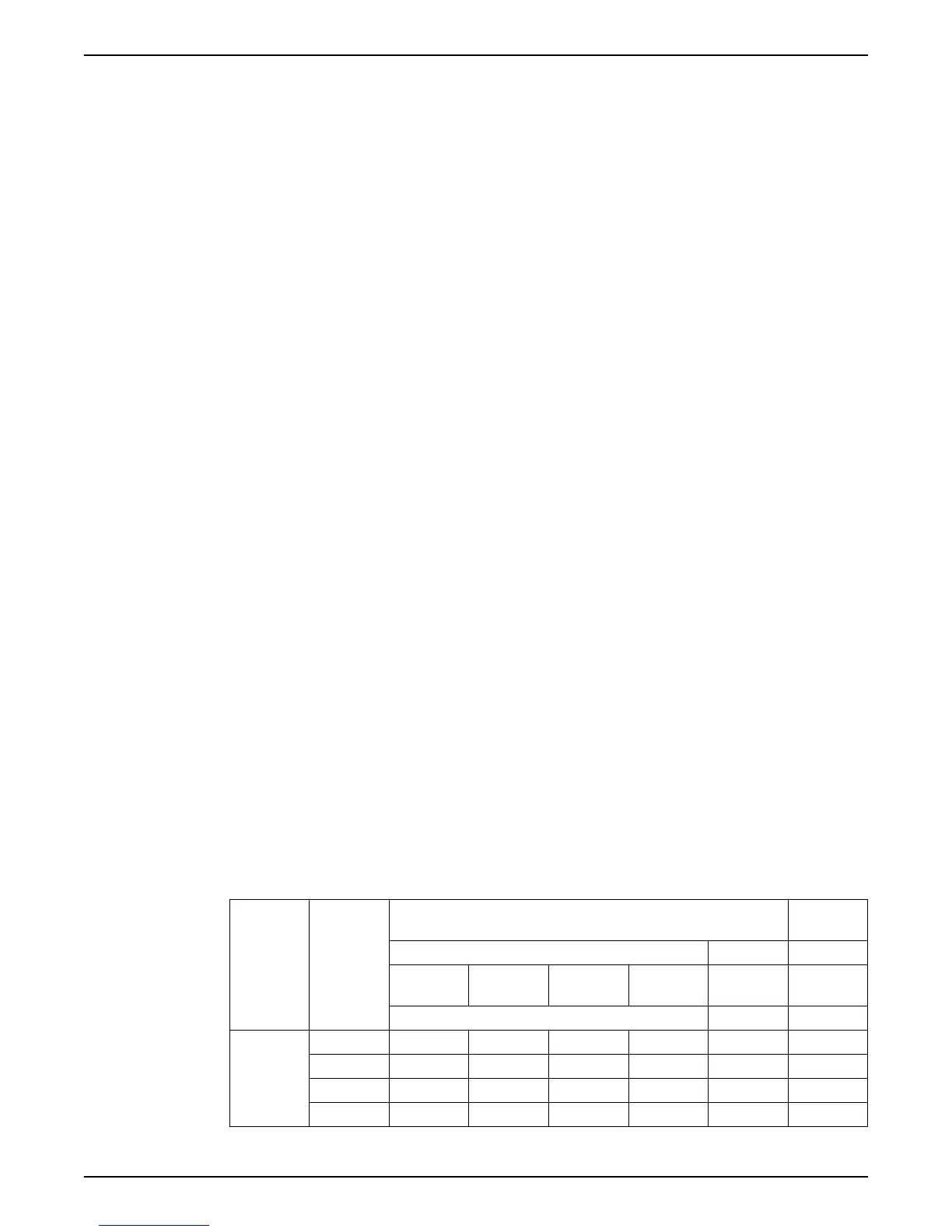

Table 1: Recommended fuses and circuit breakers

Voltage

supply

HVL

Fuse Circuit

breaker

UL Non UL

Bussmann Edison Littelfuse Ferraz-

Shawmut

Fuse ABB

Type T Type gG MCB S200

1~ 230 VAC

2.015 JJN-20 TJN (20) JLLN 20 A3T20 20 S201-C20

2.022 JJN-25 TJN (25) JLLN 25 A3T25 25 S201-C25

2.030 JJN-35 TJN (35) JLLN 35 A3T35 35 S201-C32

2.040 JJN-35 TJN (35 JLLN 35 A3T35 35 S201-C40

6 Electrical Installation

HVL 2.015-4.220 Installation, Operation, and Maintenance Manual 27

Loading...

Loading...