6.3 Wire type and ratings

• All wiring must comply with local and national regulations regarding cross section and

ambient temperature requirements.

• Use cables with a minimum heat resistance of +70 °C (158 °F); to obey the UL

(Underwriters Laboratories) regulations, it is recommended that all power connections

be made with a minimum 75°C rated copper wire of the following types: THW, THWN.

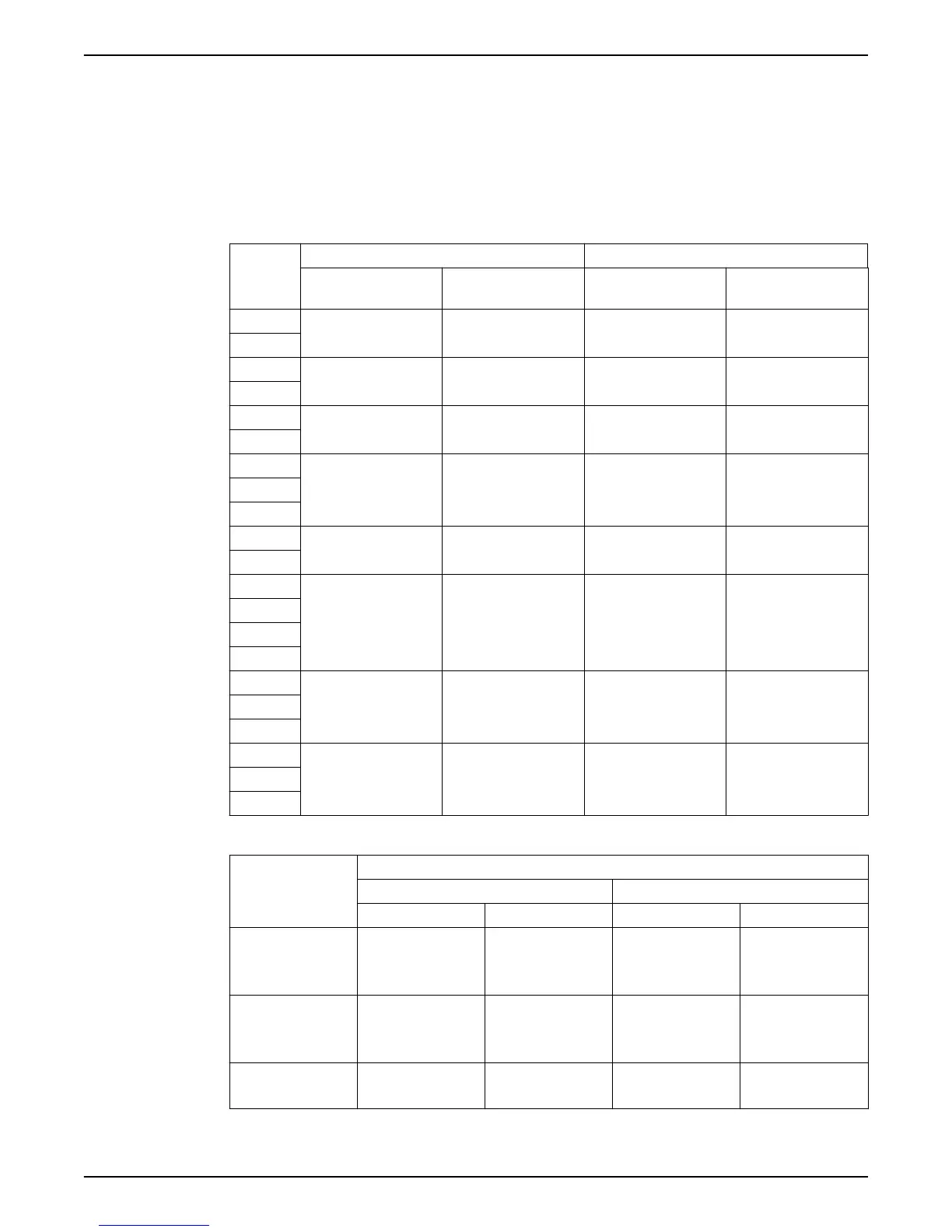

Table 2: Recommended power connections cables

HVL Power supply input cable + PE Motor output cables + PE

Wire numbers x Max.

copper section

Wire numbers x Max.

AWG

Wire numbers x Max.

copper section

Wire numbers x Max.

AWG

2.015 3 x 2mm

2

3 x 14AWG 4 x 2mm

2

4 x 14AWG

2.022

2.030 3 x 6mm

2

3 x 10AWG 4 x 6mm

2

4 x 10AWG

2.040

3.015 4 x 2mm

2

4 x 14AWG 4 x 2mm

2

4 x 14AWG

3.022

3.030 4 x 6mm

2

4 x 10AWG 4 x 6mm

2

4 x 10AWG

3.040

3.055

3.075 4 x 16mm

2

4 x 5AWG 4 x 16mm

2

4 x 5AWG

3.110

4.015 4 x 2mm

2

4 x 14AWG 4 x 2mm

2

4 x 14AWG

4.022

4.030

4.040

4.055 4 x 6mm

2

4 x 10AWG 4 x 6mm

2

4 x 10AWG

4.075

4.110

4.150 4 x 16mm

2

4 x 5AWG 4 x 16mm

2

4 x 5AWG

4.185

4.220

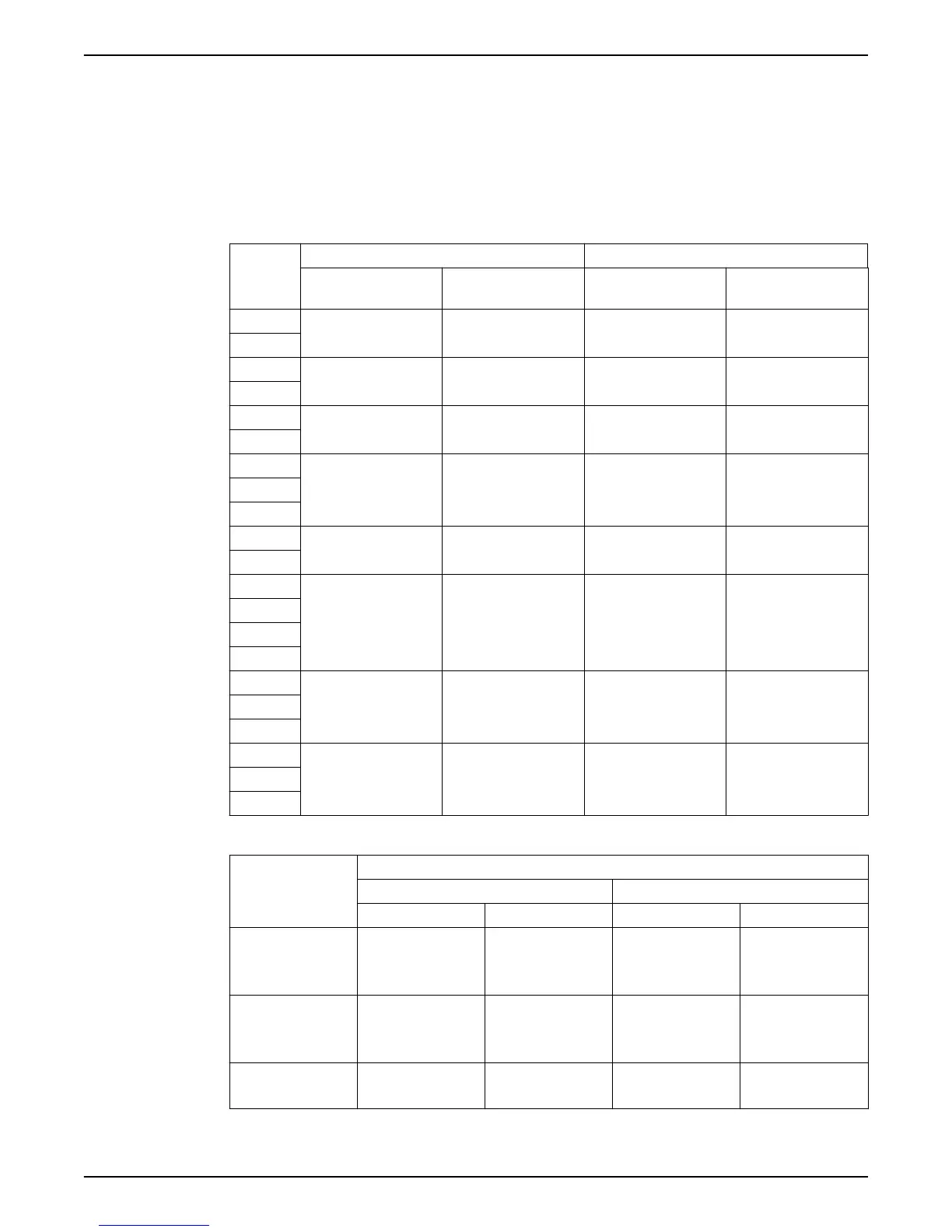

Table 3: Tightening torques for power connections

HVL

Tightening torque

Mains and motor cable terminals Earth conductor

Nm lb-in Nm lb-in

2.015 ÷ 2.022

3.015 ÷ 3.022

4.015 ÷ 4.040

0.8 7.1 3 26.6

2.030 ÷ 2.040

3.030 ÷ 3.055

4.055 ÷ 4.110

1.2 10.6 3 26.6

3.075 ÷ 3.110

4.150 ÷ 4.220

1.2 10.6 3 26.6

6 Electrical Installation

HVL 2.015-4.220 Installation, Operation, and Maintenance Manual 29

Loading...

Loading...