7-2

7

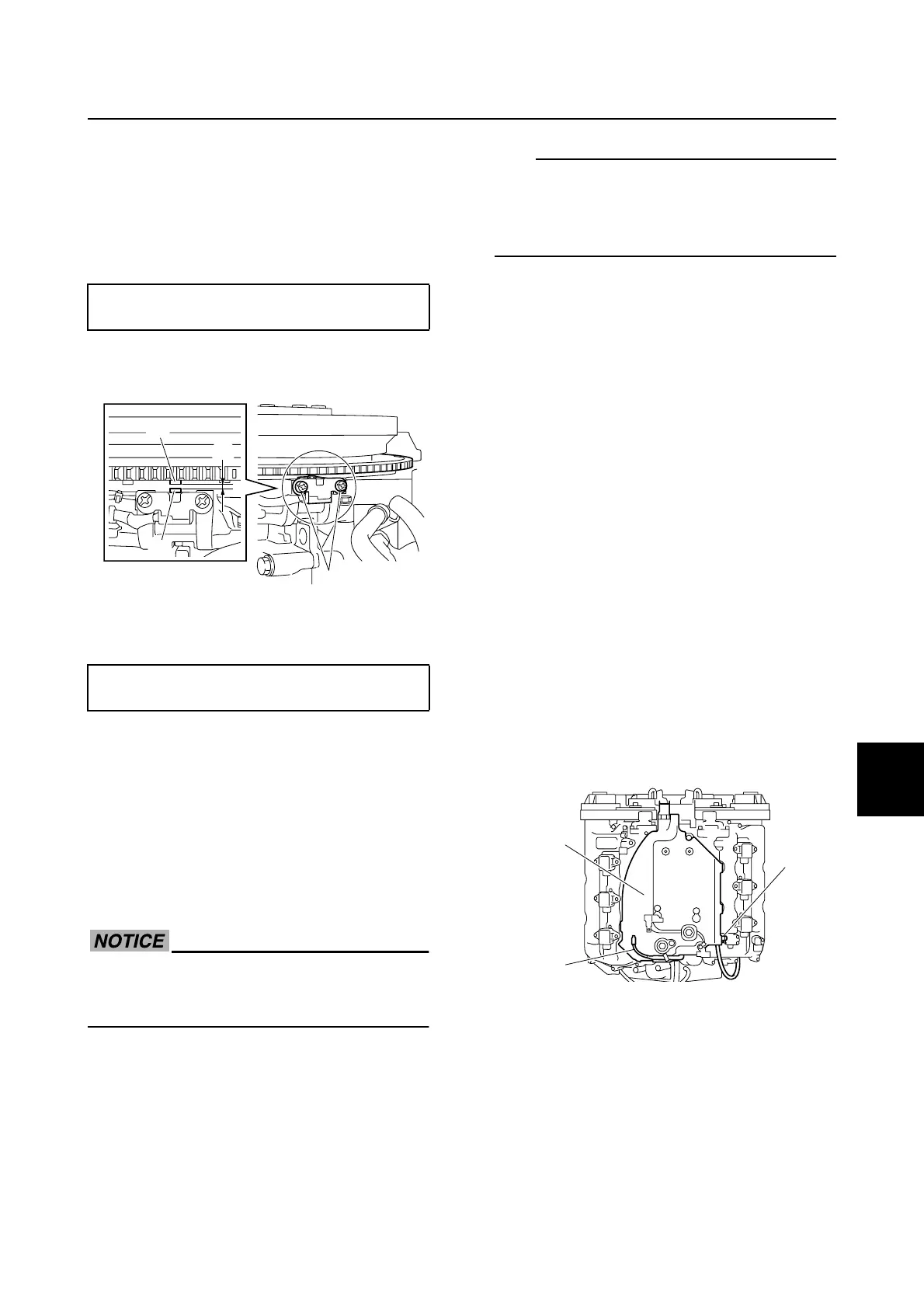

2. Turn the flywheel magnet clockwise to

align the protrusion a on the flywheel

magnet with the protrusion b on the

pulser coil.

3. Measure the pulser coil air gap c. Adjust

if out of specification.

4. Loosen the pulser coil screws 1 and

adjust the pulser coil air gap.

5. Tighten the pulser coil screws 1, and

then check the pulser coil air gap.

6. Install the wiring harness guide and wir-

ing harness guide bolts. See “Installing

the wiring harness” (7-23).

7. Install the flywheel magnet cover.

Checking the valve clearance

Measure the valve clearances when the

engine is cold.

Do not turn the flywheel magnet counter-

clockwise. Otherwise, the water pump

impeller could be damaged.

1. Reduce the fuel pressure. See “Reduc-

ing the fuel pressure” (6-7).

TIP:

When measuring or adjusting the valve clear-

ances, the fuel line must be disconnected, so

make sure to reduce the fuel pressure before

performing the disassembly procedure.

2. Remove the flywheel magnet cover and

engine ECM cover.

3. Remove the blowby hose. See “Remov-

ing the intake silencer” (6-17).

4. Remove the speed sensor coupler from

the bracket. See step 16 in “Removing

the power unit” (7-8).

5. Remove the wiring harness from the

engine ECM bracket and holder. See

steps 4–16 in “Removing the wiring har-

ness” (7-20).

6. Remove the ignition coils and spark

plugs.

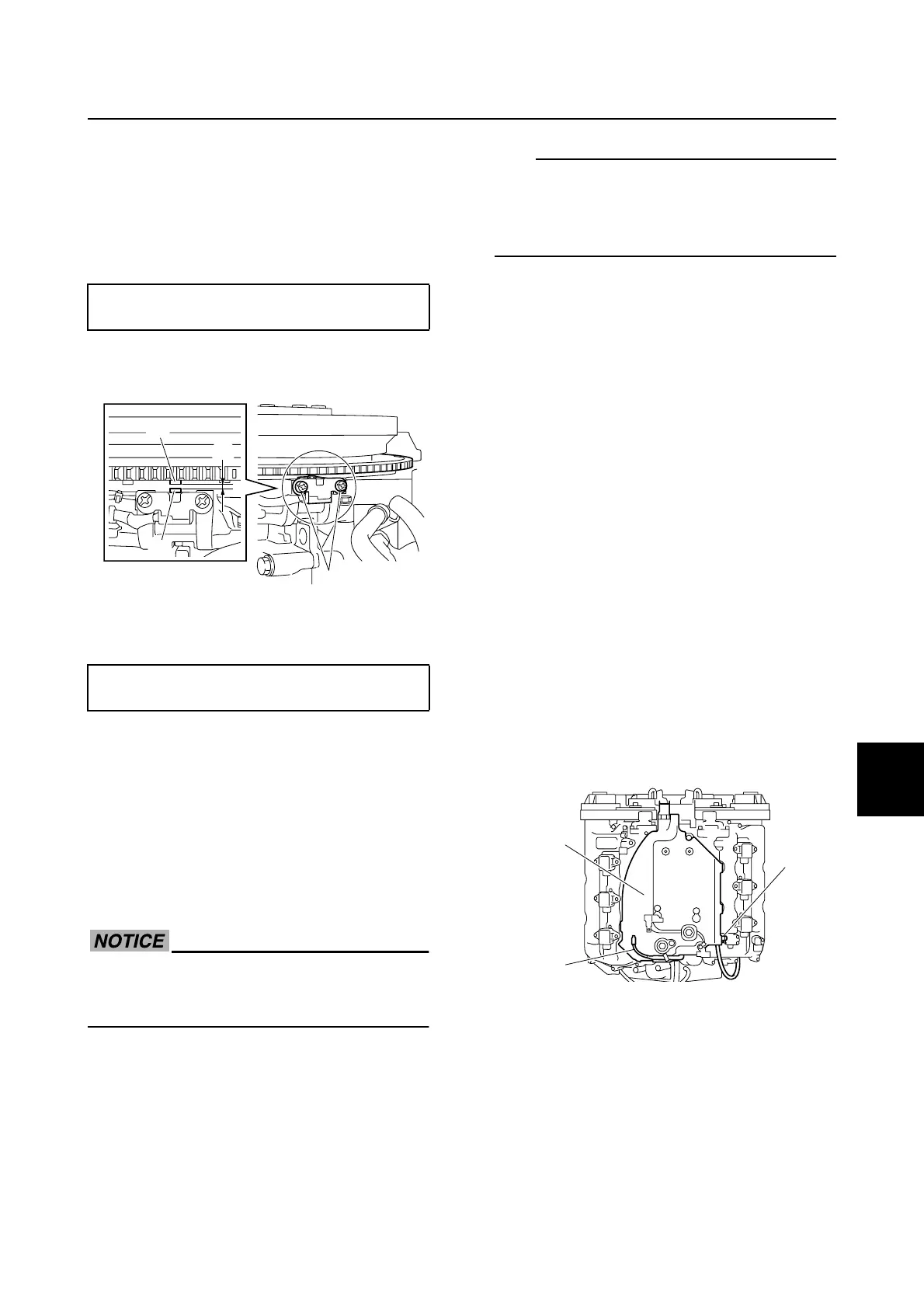

7. Disconnect the cooling water hose 1.

8. Remove the knock sensor lead a from

the engine ECM bracket 2.

9. Remove the engine ECM bracket 2.

10. Turn the flywheel magnet clockwise and

align the “1TDC” mark b on the flywheel

magnet with the pointer c.

11. Check that the “II” marks d on the VCT

assembly (PORT) and driven sprocket

(PORT) are aligned, and check that the

“I” marks e on the VCT assembly

(STBD) and driven sprocket (STBD) are

aligned.

Pulser coil air gap c:

1.4–1.6 mm (0.055–0.063 in)

Pulser coil screw 1:

4 N·m (0.4 kgf·m, 3.0 ft·lb)

a

1

c

b

2

a

1

Power unit (check and adjustment)

Loading...

Loading...