69J1D11

5-52

1

2

3

4

5

6

7

8

9

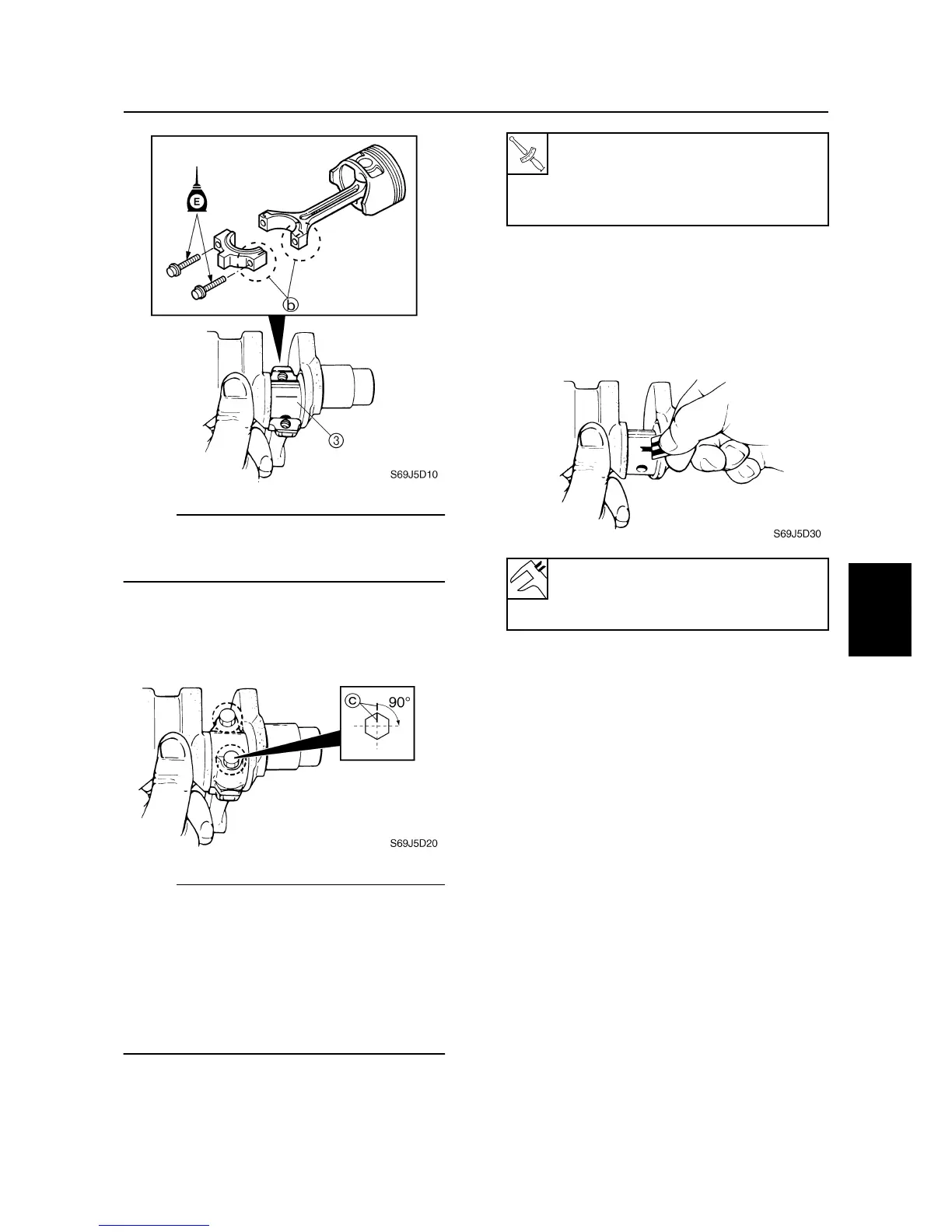

NOTE:

Align the marks

b

on the connecting rod cap

and connecting rod, which you made during

disassembly.

6. Tighten the connecting rod bolts to the

specified torques in three stages.

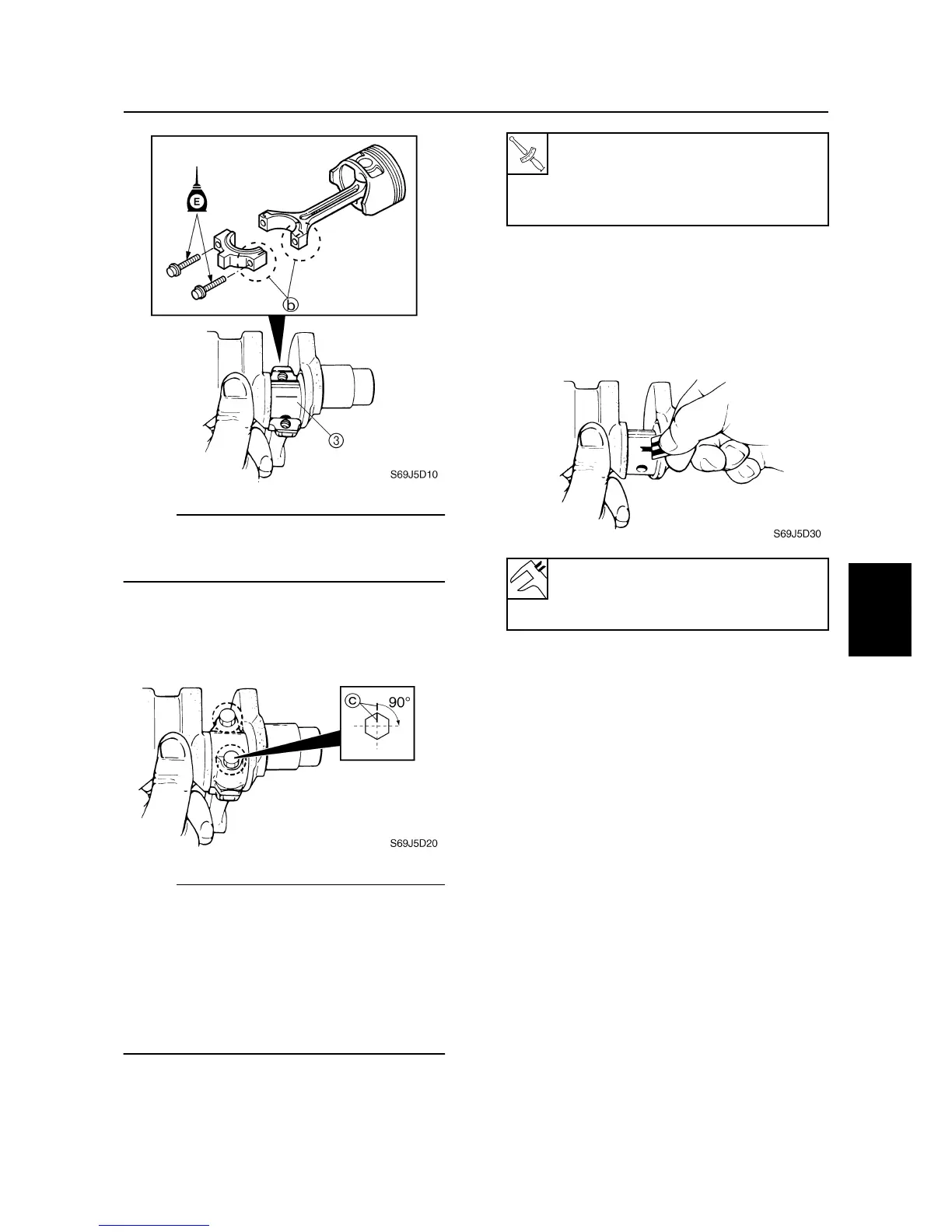

NOTE:

• Reuse the removed connecting rod bolts

when checking the oil clearance.

• Do not turn the connecting rod until the

crankpin oil clearance measurement has

been completed.

• Make a mark

c

on the connecting rod

bolts, connecting rod caps, and then tighten

the bolts 90° from the mark.

7. Remove the connecting rod cap and

measure the width of the compressed

Plastigauge (PG-1) on each crankpin.

Replace the connecting rod bearing if out

of specification.

Selecting the connecting rod bearing

1. When replacing the connecting rod bear-

ing, select the suitable bearing as fol-

lows.

2. Check the crankpin mark

a

on the

crankshaft.

Connecting rod bolt:

1st: 23 N·m (2.3 kgf·m, 17 ft·lb)

2nd: 48 N·m (4.8 kgf·m, 35 ft·lb)

3rd: 90°

Crankpin oil clearance:

0.035–0.071 mm

(0.0014–0.0028 in)

Cylinder block

Loading...

Loading...