Setting 4: oL3/oL4 at Run - Fault

Overtorque detection works whenever a Run command is active. The operation is stopped and an oL3/oL4 fault is triggered.

Setting 5: UL3/UL4 at Speed Agree - Alarm

Undertorque detection is active only when the output speed is equal to the frequency reference, i.e., no detection during

acceleration and deceleration. The operation continues after detection and a UL3/UL4 alarm is triggered.

Setting 6: oL5/UL5 at Run - Alarm

Undertorque detection works whenever a Run command is active. The operation continues after detection and an oL5/UL5

alarm is triggered.

Setting 7: UL5 at Speed Agree - Fault

Undertorque detection is active only when the output speed is equal to the frequency reference, i.e., no detection during

acceleration and deceleration. The operation is stopped and a UL5 fault is triggered.

Setting 8: oL3/oL4 at Run - Fault

Undertorque detection works whenever a Run command is active. The operation is stopped and an oL3/oL4 fault is triggered.

Setting 9: UL6 Alarm at Speed Agree

Setting 10: UL6 Alarm during Run

Setting 11: UL6 Fault at Speed Agree

Setting 12: UL6 Fault during Run

n

L6-02/L6-05: Torque Detection Level 1/2

These parameters the detection levels for the torque detection functions 1 and 2.

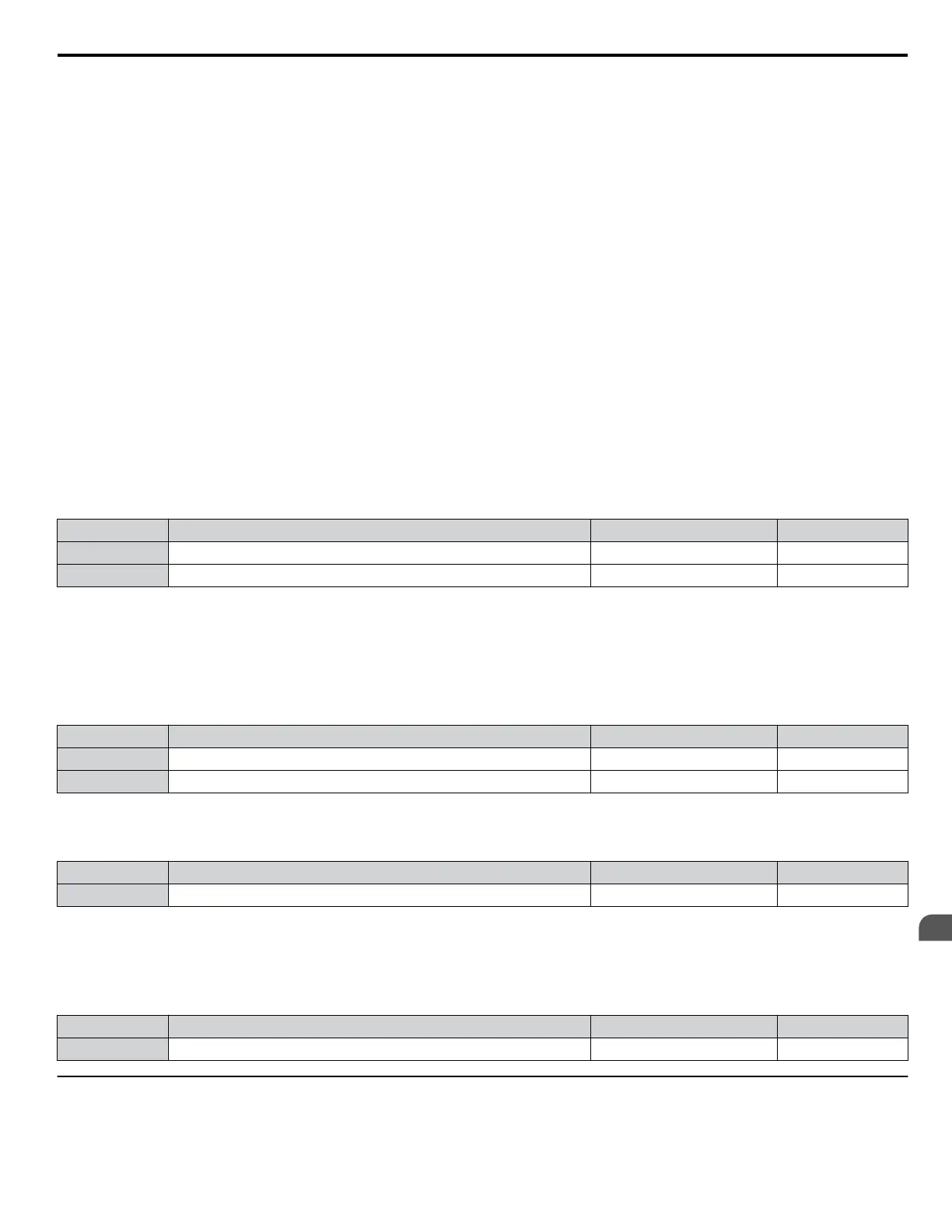

No. Name Setting Range Default

L6-02 Torque Detection Level 1 0 to 300% 150%

L6-05 Torque Detection Level 2 0 to 300% 150%

Note: 1. The torque detection level 1 (L6-02) can also be supplied by an analog input set to H3-02/10 = 7. In this case the analog value has priority

and the setting L6-02 is disregarded. Torque detection level 2 (L6-05) cannot be set by an analog input.

2. The detection levels for overtorque and undertorque are set as a percentage of the drive rated current when using V/f Control or Open

Loop Vector Control. When using Closed Loop Vector Control, the drive sets torque detection as a percentage of the motor rated current.

n

L6-03/L6-06: Torque Detection Time 1/2

These parameters set the time that the levels set in L6-02/05 have to be exceeded before an alarm/fault is triggered.

No. Name Setting Range Default

L6-03 Torque Detection Time 1 0.0 to 10.0 s 0.1 s

L6-06 Torque Detection Time 2 0.0 to 10.0 s 0.1 s

n

L6-13: Motor Underload Protection Selection

Sets the motor underload protection (UL6) based on motor load.

No. Name Setting Range Default

L6-13 Motor Underload Protection Selection 0, 1 0

Setting 0: Base frequency enable

Setting 1: Max frequency enable

n

L6-14: Motor Underload Protection Level at Minimum Frequency

Sets the motor underload protection (UL6) based on motor load.

No. Name Setting Range Default

L6-14 Motor Underload Protection Level at Minimum Frequency 0 to 300% 15%

u

L8: Hardware Protection

5.8 L: Protection Functions

YASKAWA TOEP YAIQPM 03B YASKAWA AC Drive - iQpump Micro User Manual

207

5

Parameter Details

Loading...

Loading...