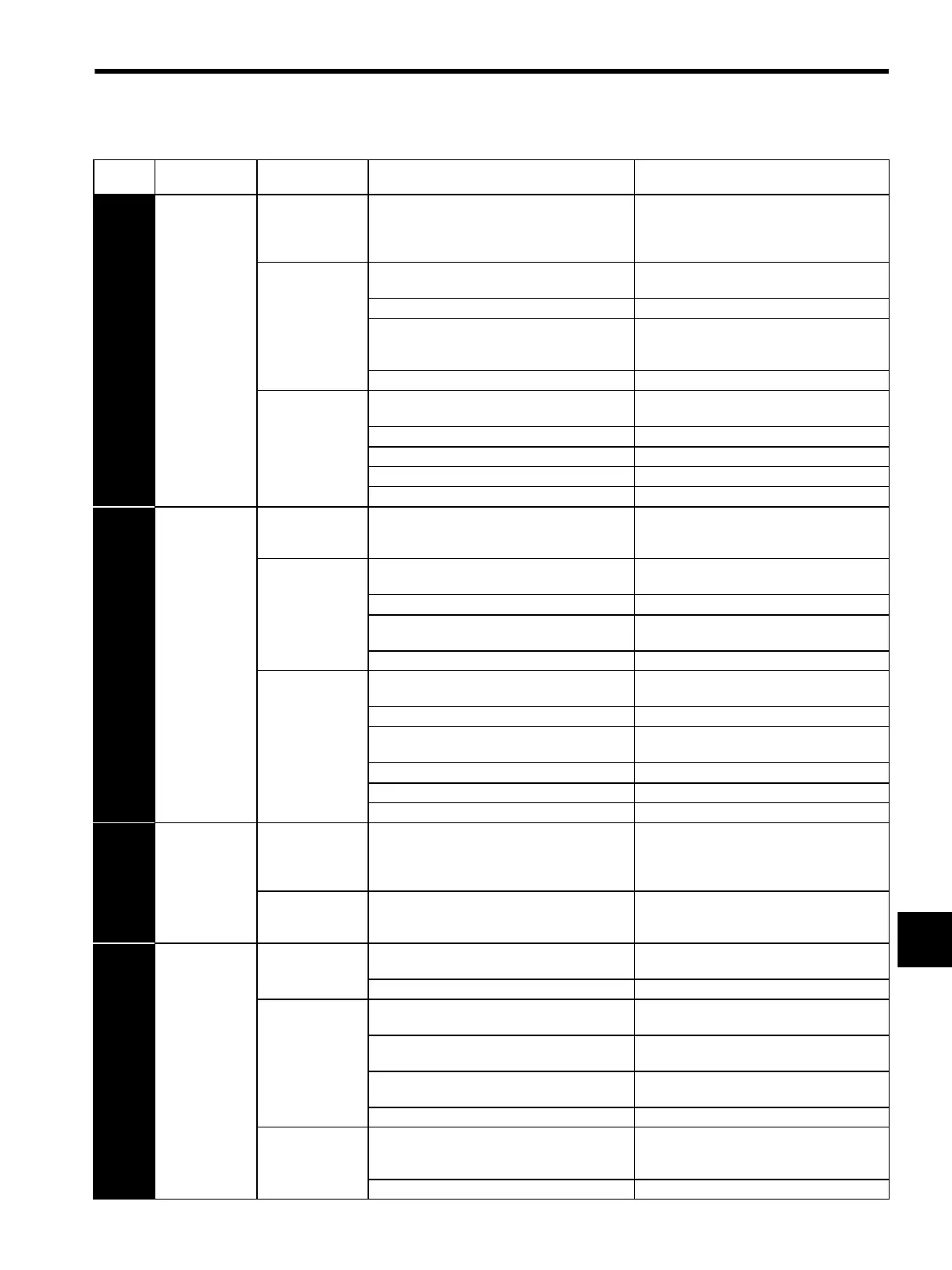

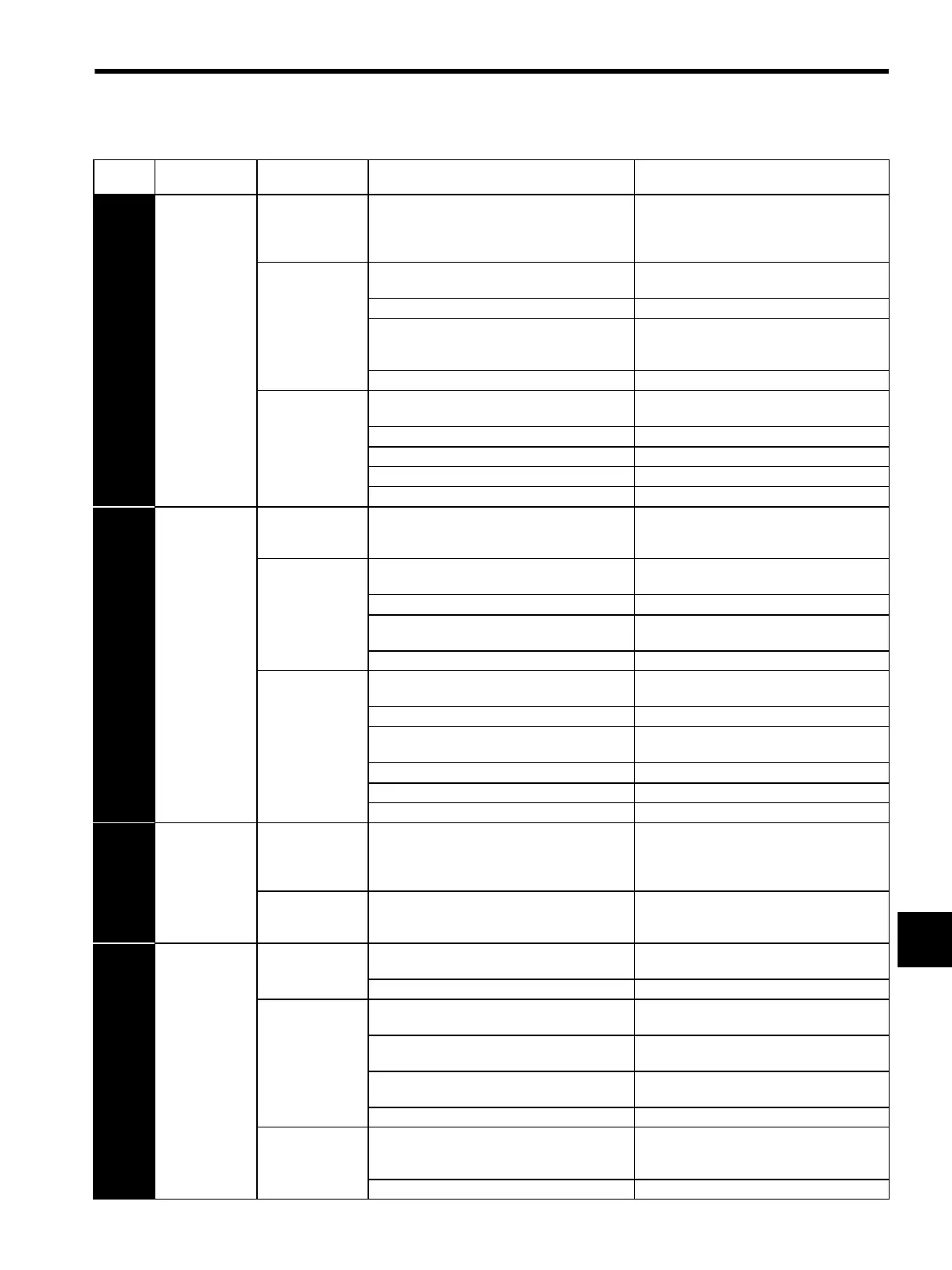

9.1 Troubleshooting

9-9

9

A.410

Undervoltage

(Detected when

the

SERVOPACK

main circuit DC

voltage is

approx. 170 V or

less.)

(Detected when

the power to the

main circuit was

turned ON)

Occurred when the

control power sup-

ply was turned

ON.

A SERVOPACK board fault occurred. Replace the SERVOPACK.

Occurred when the

main circuit power

supply was turned

ON.

The AC power supply voltage is 120 V or less. AC power supply voltage must be within the

specified range.

The fuse of the SERVOPACK is blown out. Replace the SERVOPACK.

Inrush current limit resistor disconnection

(abnormal power supply voltage? inrush current

limit resistor overload?)

Replace the SERVOPACK (check the power

supply voltage, and reduce the number of times

of main circuit ON/OFF operation.)

A SERVOPACK fault occurred. Replace the SERVOPACK.

Occurred during

normal operation.

Lowered AC power supply voltage (large voltage

drop?)

AC power supply voltage must be within the

specified range.

A temporary power failure occurred. Reset the alarm and restart the operation.

The servomotor cable is short-circuited. Repair or replace the servomotor cable.

The servomotor is short-circuited. Replace the servomotor.

A SERVOPACK fault occurred. Replace the SERVOPACK.

A.510

Overspeed

(Detected when

the feedback

speed is the max-

imum motor

speed × 1.1 or

more.)

Occurred when the

control power sup-

ply was turned ON

A SERVOPACK board fault occurred. Replace the SERVOPACK.

Occurred in servo

ON status.

Incorrect order of phases U, V, and W in the ser-

vomotor wiring.

Correct the servomotor wiring.

The encoder wiring is incorrect. Correct the encoder wiring.

Malfunction due to noise interference in the

encoder wiring

Take measures against noise for the encoder

wiring.

A SERVOPACK fault occurred. Replace the SERVOPACK.

Occurred when the

servomotor started

running or at high

speed run.

Incorrect order of phases U, V, and W in the ser-

vomotor wiring.

Correct the servomotor wiring.

The encoder wiring is incorrect. Correct the encoder wiring.

Malfunction occurred due to noise interference in

the encoder wiring

Take measures against noise for the encoder

wiring.

The position/speed reference input is too large. Reduce the reference value.

The setting of reference input gain is incorrect. Correct the reference input gain setting.

A SERVOPACK board fault occurred. Replace the SERVOPACK.

A.710

Overload: High

Load

Occurred when the

control power sup-

ply was turned

ON.

A SERVOPACK board fault occurred. Replace the SERVOPACK.

Occurred when the

servo was turned

ON.

Faulty servomotor wiring (faulty wiring and con-

nection)

Correct the servomotor wiring.

A.720

Overload:

Low Load

Occurred when the

servo was turned

ON.

Faulty encoder wiring (faulty wiring and connec-

tion)

Correct the encoder wiring.

A SERVOPACK fault occurred. Replace the SERVOPACK.

Occurred when the

servomotor did not

run by the refer-

ence input.

Faulty servomotor wiring (faulty wiring and con-

nection)

Correct the servomotor wiring.

Faulty encoder wiring (faulty wiring and connec-

tion)

Correct the encoder wiring.

The starting torque exceeds the maximum torque. Reconsider the load and operation conditions,

or reconsider the servomotor capacity.

A SERVOPACK fault occurred. Replace the SERVOPACK.

Occurred during

normal operation.

The effective torque exceeds the rated torque, or

the starting torque largely exceeds the rated

torque.

Reconsider the load and operation conditions,

or reconsider the servomotor capacity.

A SERVOPACK fault occurred. Replace the SERVOPACK.

Table 9.3 Alarm Display and Troubleshooting (Cont’d)

Alarm

Display

Alarm Name

Situation at Alarm

Occurrence

Cause Corrective Actions

SIEPS80000025.book 9 ページ 2004年10月25日 月曜日 午前11時57分

Loading...

Loading...