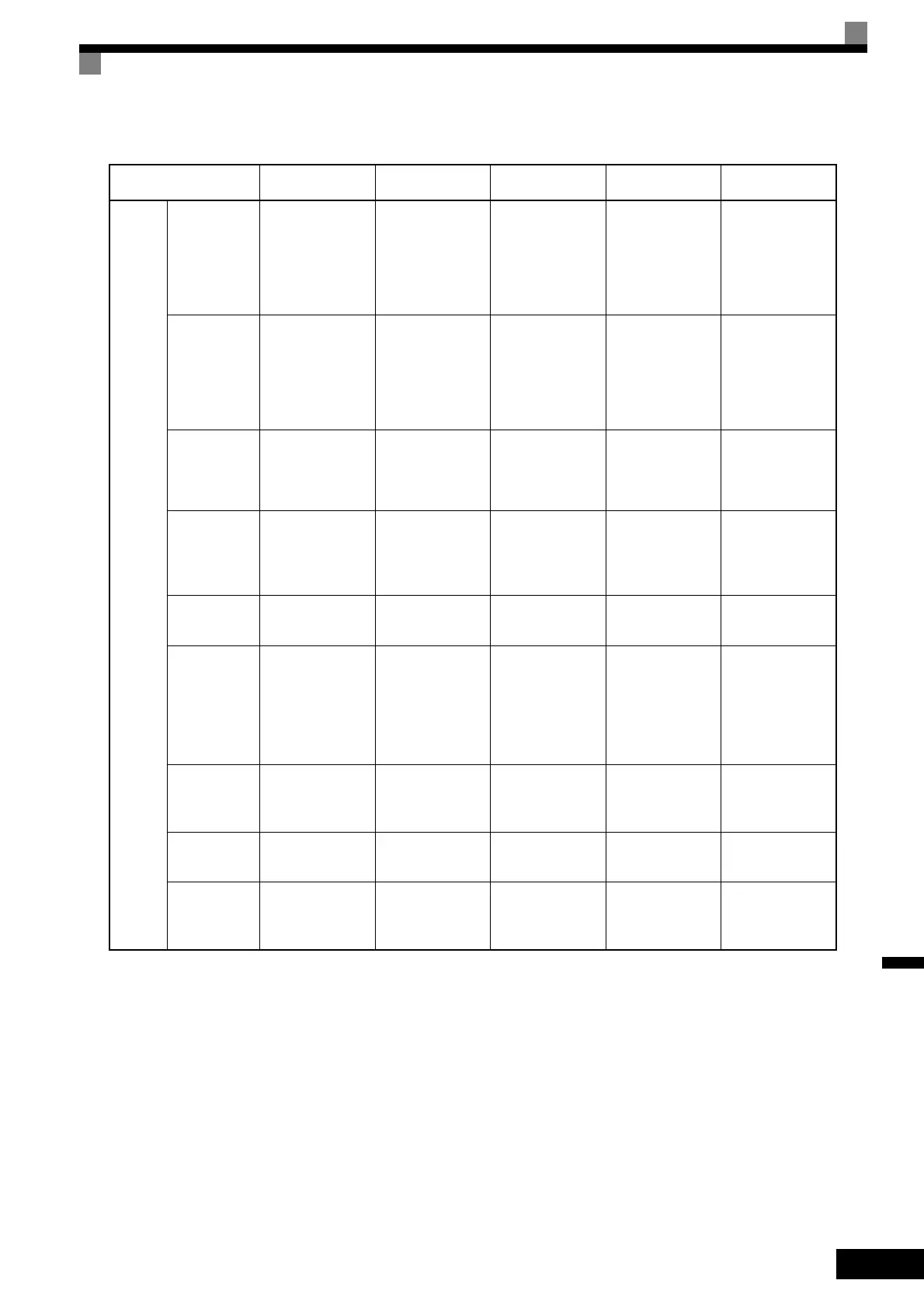

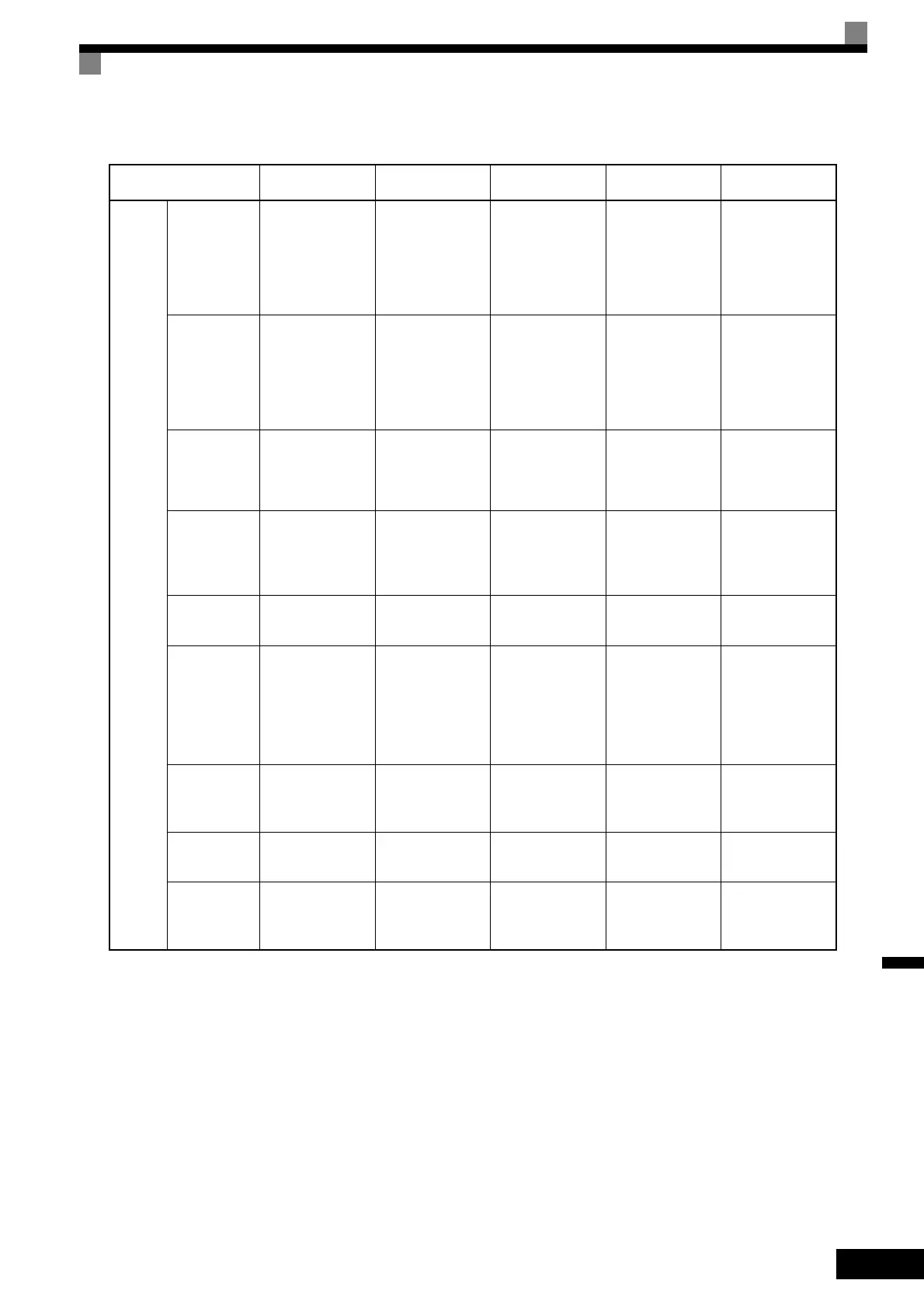

Varispeed G7 Control Methods

10-

3

* 1. The variable speed control range. (For continuous operation, the motor's temperature rise must be considered.)

* 2. The speed deviation in relation to the maximum speed with a rated load and when the load is stable. (For open-loop vector 1 and 2 control, the motor temperature

must be 25°C ± 10°C.)

* 3. The speed response guidelines indicating the extent of the motor's actual speed gain in proportion to the speed reference, which changes in a sinusoidal wave

form, within a range where motor torque does not become saturated.

* 4. A guideline for the motor torque that can be generated when started at a low speed and its output frequency (rotations) at that time.

* 5. This function limits the maximum motor torque to protect the machine and the load.

* 6. This function directly controls the amount of torque being generated at the motor and its rotation direction, e.g., to control force.

* 7. This function controls the amount of motor slip that occurs to prevent mechanical shock, when replacing a torque motor, etc.

* 8. This function performs simple positioning control (servo lock), without using an external positioning control device.

* 9. This function instantaneously estimates (or detects) the speed and rotation direction of a coasting motor, and quickly starts it without subjecting it to shock.

* 10.This function automatically adjusts the voltage applied to the motor to optimize the motor's efficiency with light loads.

* 11.This function improves the deceleration time without using a braking resistor by making the motor winding absorb regenerative power. As a standard, this func-

tion is effective with a motor running on 160 kW or less with a high-inertia load.

* 12.This function enables proportional gain in relation to changes in the speed reference, even for low rigidity (corresponds to the servo's model gain control).

* 13.Set the maximum output frequency (E1-04) for open-loop vector 2 control to 60 Hz max. (120 Hz max. for PRG 102). For torque control on the regenerative

side, use in the speed range 1:10.

Appli-

cation

Func-

tions

Autotuning

Line-to-line resis-

tance (Normally

not required.)

Line-to-line resis-

tance (Normally

not required.)

Rotational auto-

tuning, stationary

autotuning, sta-

tionary autotuning

for line-to-line

resistance only

Rotational auto-

tuning, stationary

autotuning, sta-

tionary autotuning

for line-to-line

resistance only

Rotational auto-

tuning, stationary

autotuning, sta-

tionary autotuning

for line-to-line

resistance only

Torque

Limiting

*5

No No

Yes (except during

acceleration/decel-

eration, below

minimum fre-

quency, or during

reverse rotation)

Yes

Yes (except below

minimum fre-

quency and during

reverse rotation)

Torque

Control

*6

No No No Yes

Yes (except below

minimum fre-

quency and during

reverse rotation)

Droop

Control

*7

No No No

Yes (except for

0min

−1

and

during reverse

rotation)

Yes (Except below

minimum fre-

quency and during

reverse rotation)

Zero-servo

Control

*8

No No No Yes No

Speed Estima-

tion

(Detection)

Instantaneous

Speed

Search

*9

Yes (speed and

rotation direction

estimation)

Yes (speed detec-

tion and rotation

direction estima-

tion)

Yes (speed and

rotation direction

estimation)

Yes (speed and

rotation direction

detection)

Yes (speed and

rotation direction

estimation)

Automatic

Energy-sav-

ing Control

*10

Yes Yes Yes Yes Yes

High-slip

Braking

*11

Yes Yes

(Under

development)

(Under

development)

(Under

development)

Feed

Forward

Control

*12

No No No Yes Yes

Table 10.1 Overview and Features of Control Methods (Continued)

Control Method V/f Control

V/f Control with

PG

Open-loop Vec-

tor 1 Control

Flux Vector Con-

trol

Open-loop Vec-

tor 2 Control

TOE-S616-60.1.book 3 ページ 2017年8月4日 金曜日 午後3時41分

Loading...

Loading...