6

-172

Using Inverters for Elevating Machines

This section describes precautions to be observed when using the Varispeed G7 for elevating machines

such as elevators and cranes.

Brake ON/OFF Sequence

Brake ON/OFF Sequence

For the holding brake’s ON/OFF sequence, use the following Inverter output signals according to the set con-

trol method.

* 1. This example shows multi-function output terminals M1-M2 used for the holding brake ON/OFF signal.

Do not set H2-01 to 0 (During run).

* 2. This is the standard setting range for open-loop vector 1 control. For V/f control, set to approximately the motor rated slip frequency +0.5 Hz.

If the set value is too low, the motor torque is insufficient and the load may slip when the brake is applied. Be sure to set L4-01 to a value larger than that

of E1-09 (Min. output frequency) and larger than that of L4-02 shown in Figure 6.86. If the set value is too large, the motor may not run smoothly when

it starts running.

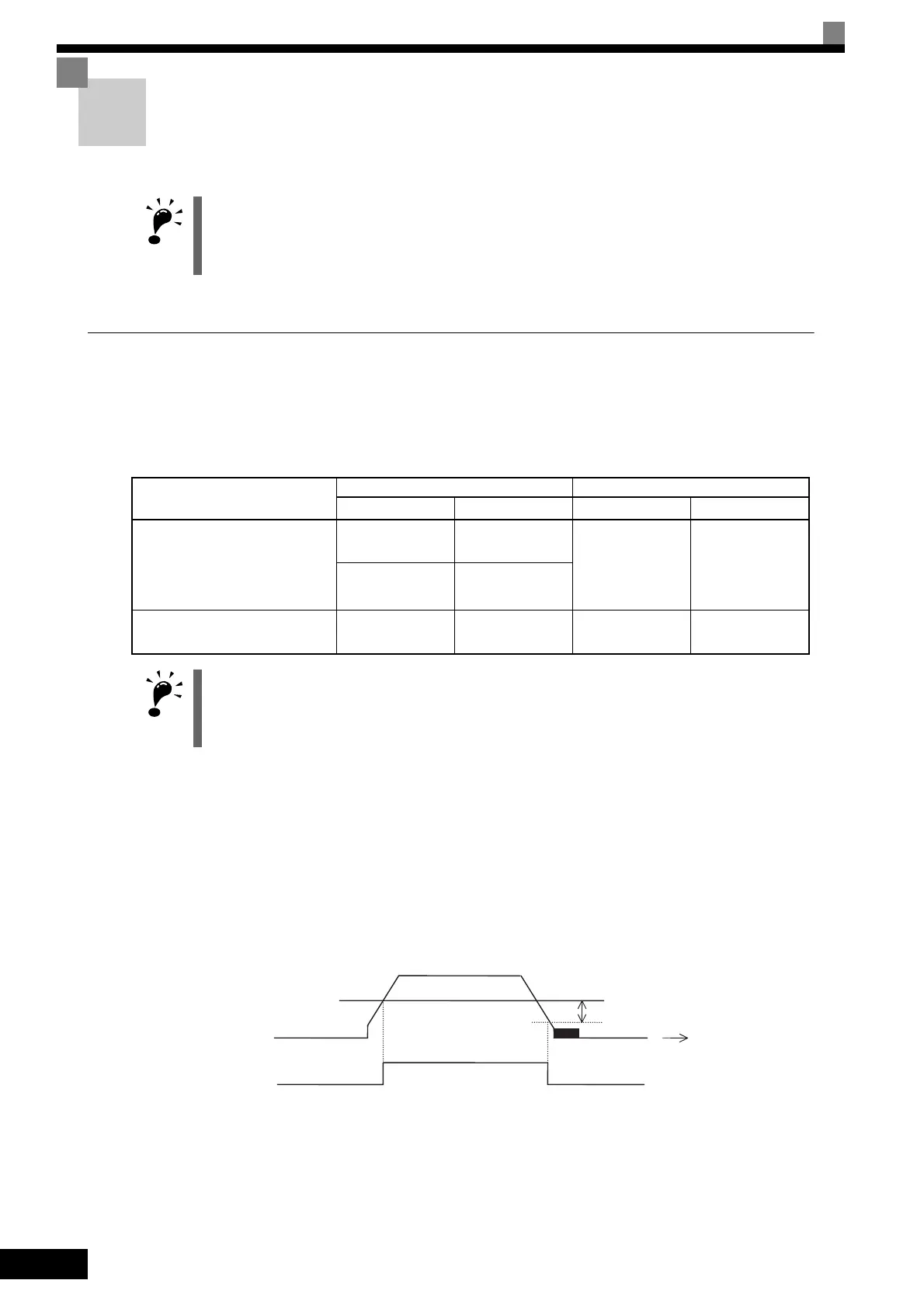

* 3. The hysteresis in frequency detection 2 can be adjusted (from 0.1 to 0.5 Hz) by L4-02 (speed agree detection width). Change the setting to approxi-

mately 0.1 Hz if there are drops while stopping.

* 4. Applicable for G7-Series Inverters with software versions PRG 1038 and later.

* 5. When using frequency detection 2, set L4-01 before H2-01. If H2-01 is set before L4-01, the holding brake will engage while stopping. For Inverters

with software versions PRG 1038 and later, use frequency detection 5 in which a holding brake signal is OFF when the Inverter is baseblocked.

Fig 6.86

When performing trial operation, enable Current alarm function (L8-41 =1), and be sure to make adjustments

to the braking sequence by using Peak hold functions (refer to Current Alarm Function and Peak Hold Cur-

rent Monitoring Function in Chapter 6 ) so that the startup current is less than 150% of the Inverter rated cur-

rent.

Control Method

Brake ON/OFF Signal Brake ON/OFF Level Adjustment

Signal Name

Constant

*1

Signal Name Constant

V/f (A1-02 = 0)

V/f with PG (A1-02 = 1)

Open-loop vector 1 (A1-02 = 2,

factory setting)

Frequency detec-

tion 2

H2-01 = 05

*5

• Speed agree

detection level

• Speed agree

detection width

• L4-01 = 1.0 to

3.0 Hz

*2

• L4-02 = 0.1 to

0.5 Hz

*3

Frequency detec-

tion 5

*4

H2-01 = 36

*5

Flux vector (A1-02 = 3) During run 2 H2-01 = 37

Zero-speed level

(OFF timing only)

b2-01 = 0.1 to

0.5 Hz

Do not set Open-loop vector 2 for use in elevating machines.

L4-02

L4-01

OFF

ON

Frequency detection 2

Output frequency

Time

TOE-S616-60.1.book 172 ページ 2017年8月4日 金曜日 午後3時41分

Loading...

Loading...