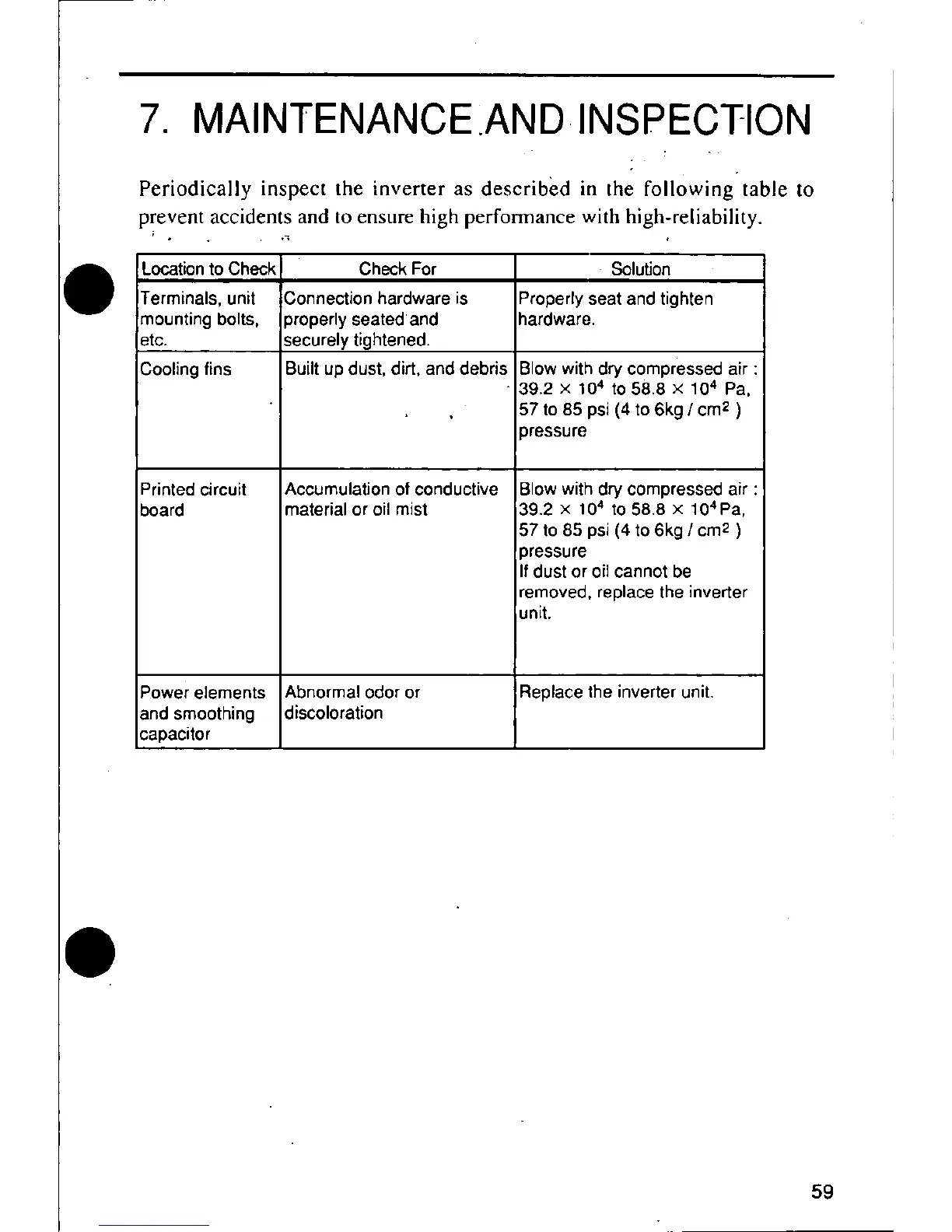

7. MAINTENANCE AND INSPECTION

Periodically inspect the inverter as described in the following table to

prevent accidents and to ensure high performance with high-reliability.

LocationtoCheck CheckFor Solution

ITerminals, unit Connection hardware is =roperly seat andtighten

"nountingbolts, properly seated and lardware.

etc. securely tightened.

Cooling fins Built up dust, dirt, and debris Blowwith dry compressed air :

39.2 x 104to 58.8 x 104 Pa,

57 to 85 psi (4 to 6kg / cm2)

pressure

Printedcircuit Accumulationof conductive Blowwith dry compressed air :

board material oroil mist i39.2 x 104 to 58.8 x 104pa,

57 to 85 psi (4 to 6kg / cm2 )

xessure

Ifdust or oil cannot be

removed,replace the inverter

unit.

Power elements Abnormalodor or Replace the inverter unit.

and smoothing discoloration

capacitor

59

Loading...

Loading...