120

YORK INTERNATIONAL

FORM 150.52-NM2 (1001)

New C.O.= Programmed C.O. x

(33.3 - Time Remaining)

33.3

This transient cutout value increases with time until af-

ter 30 seconds it equals the programmed cutout value.

If the suction pressure falls below the value as calcu-

lated by the formula relative to time, the system will

shut down on a low suction pressure fault. If the suc-

tion pressure rises above the programmed cutout value,

the 30-second timer will be reset.

If the Dip Switch on the microprocessor board is set

for “Water Cooling” (see page 124), the cutout is pro-

grammable between 3-5 bar (44-70 PSIG) for both R-

22 and R-407C models. In this mode, settings of 3 bar

(44 PSIG) for R-22 and R-407C are recommended. If

the Switch is set for “Brine Cooling” (glycol) the cut-

out is programmable between 0.3 - 5 bar (5 - 70 PSIG)

for R-22 and R-407C models. In this mode, the cutout

should typically be set to the saturated refrigerant pres-

sure equivalent to 10°C (18°F) below the temperature

of the chilled liquid. The sludge point of the glycol

MUST be at least another 11°C (20°F) below the

equivalent cutout temperature. This programmable

value is password protected.

High Compressor Motor Current Cutout:

The High Motor Current Safety protects against exces-

sively high motor current and shuts a system down and

locks it out after only a single occurrence of a rise in

average motor current above the cutout point. Motor

current is monitored through the 3 Current Transform-

ers (CTs) per motor, one on each phase, in the motor

protection module.

Average motor current is monitored after 4 seconds of

compressor operation. The system will be shut down if

average motor current exceeds 115% FLA.

FLA (full load amps) is approximately

1.2 x RLA (rated load amps). RLA is

specified on the motor / chiller name-

plate and is typical current demand

under rated operating conditions in a

fully loaded system. When a system is

fully loaded, typical motor currents

may be at 60 - 85% FLA depending on

operating conditions.

frigerant flow. A number of transient timer features pre-

vent nuisance trips during start-up, compressor loading,

etc. The Low Suction Pressure Safety is programmable

(see Section 9 [8.2] / Page 143, Low Suction Pressure

Cutout for more details).

The suction pressure cutout is ignored for the first 45

seconds of operation. During the next 180 seconds of

running , suction pressure may be lower than the cutout,

but must be greater than:

SP Cutout =

Programmed Cutout * (Run Time - 25)

200

This cutout value increases with time until after 225

seconds it equals the programmed cutout value. If suc-

tion pressure falls below the calculated cutout value

before 225 seconds of run time, the system will be shut

down.

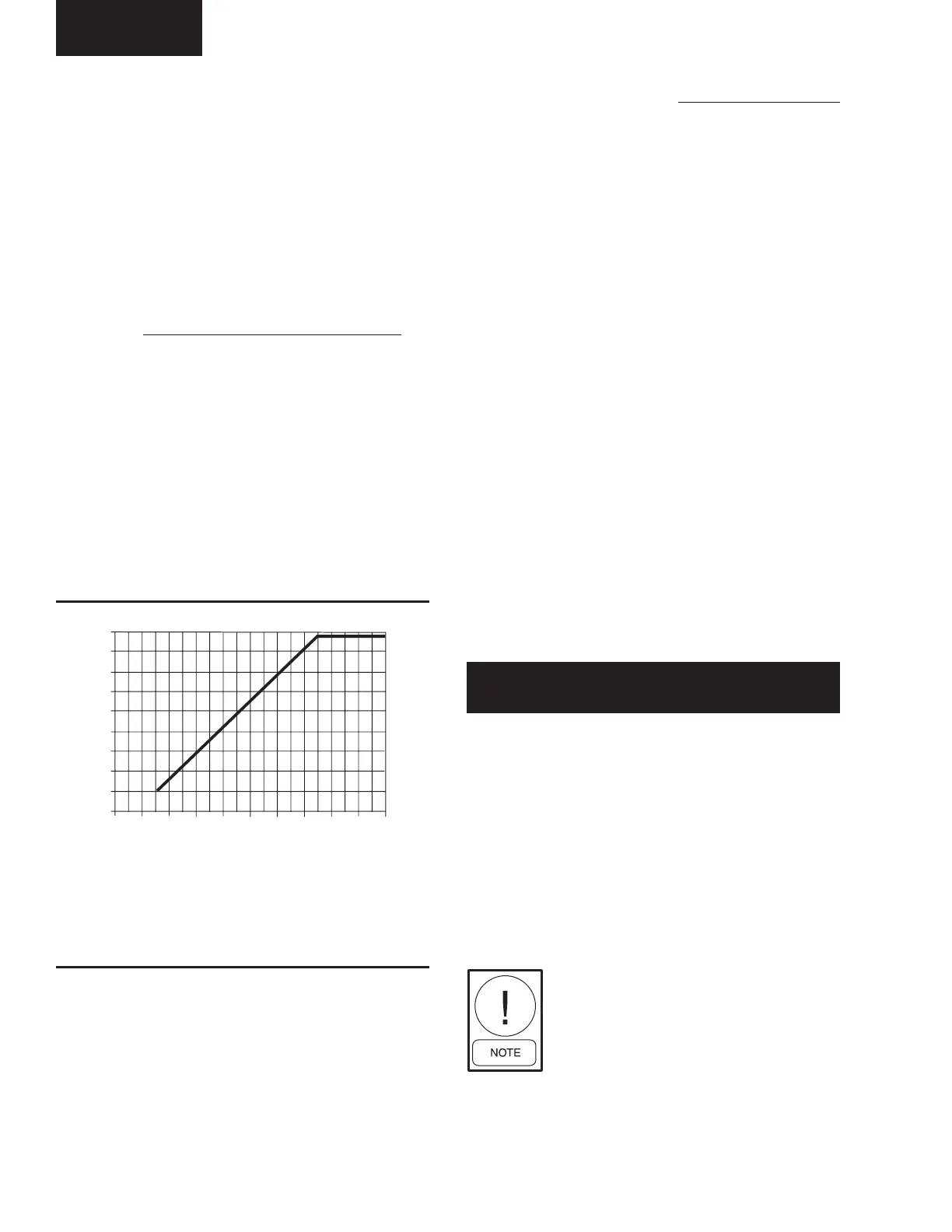

The following graph shows a typical programmed suc-

tion pressure cutout of 3 bar (44 PSIG) and its change

from time = 0 sec of compressor run time to 225 sec-

onds of compressor run time.

After 225 seconds of operation with suction pressure

operating above the cutout, a 30-second transient timer

prevents short term fluctuations in suction pressure due

to loading or fan cycling from causing shutdown. If suc-

tion pressure drops below the cutout point after 225 sec-

onds of operation, the transient timer is activated. While

the transient timer is active, suction pressure must not

drop below 10% of the cutout initially programmed and

must be greater than:

Suction Pressure Cutout With

3 bar Programmed Cutout

LD03525

0 30 60 90 120 150 180 210 240 270 310

45

40

35

30

25

20

15

10

5

0

Run Time (seconds)

Suction Pressure Cutout

FIG. 38 – SUCTION PRESSURE CUTOUT

SYS # H I GH MTR CURR

SYS # H I GH MTR CURR

Micro Panel

Loading...

Loading...