153

YORK INTERNATIONAL

FORM 150.52-NM2 (1001)

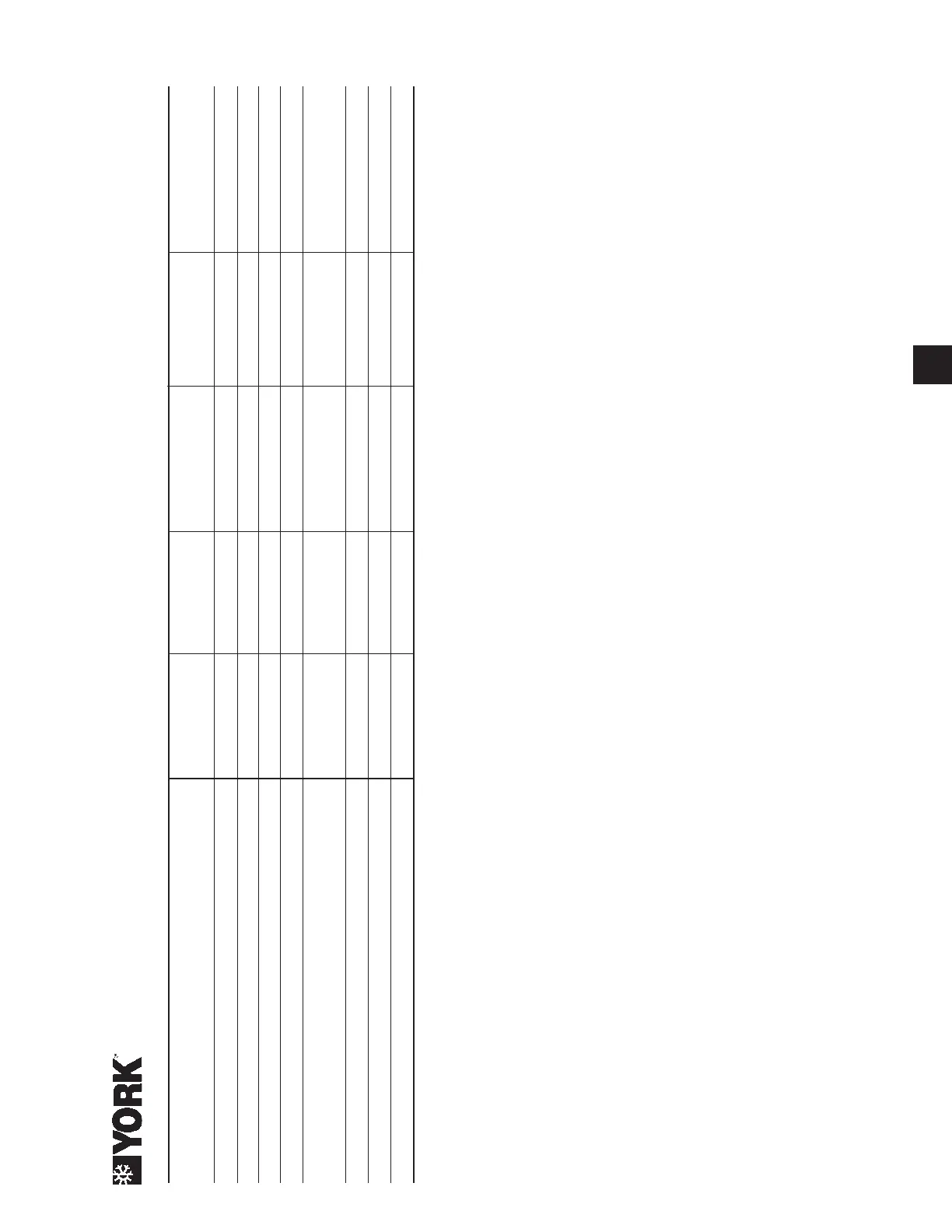

PROCEDURE WEEKLY QUARTERLY SEMI-ANNUALLY YEARLY

EVERY

___ HOURS

Check oil level X

1

Check oil appearance X

2

Leak check X

Check oil temperatures X

3

Record operating pressures, temperatures and

X

motor current readings

Check compressor superheat X

4

Change oil X

2

Replace Suction/Discharge springs

†

X

5

MAINTENANCE REQUIREMENTS FOR YORK P RECIPROCATING COMPRESSOR

*

A. Pre-Lubrication: To ensure long compressor life, pre-lubrication at the start-up and after long idle periods of several months is recommended. This manual pre-lube is especially important

on R-134a and R-407C units that employ POE-type oil due to the polar nature of these oils. This is accomplished by attaching a hand pump to the core-type access port (Schrader fitting) on

the oil pump.

B. Run hours and starts must be recorded on all maintenance and repair records for warranty reimbursement.

† An Industry-Certified Technician should perform this service. Proof of maintenance fulfillment may be required for warranty validation purposes.

* Reserved for any special site-determined requirements as determined by end user.

1. For all models, maintain oil level no higher than the midpoint of the upper sightglass and no lower than the middle of the lower sightglass.

2. Oil should be golden-colored and relatively clear. If contamination is suspected, an oil sample should be tested.

3. At idle, the crankcase oil heater should maintain a minimum oil temperature 15 to 30°F above ambient. “Oil Temp Inhibit” fault will display if 15° minimum is not met. During compressor operation,

high oil temperature/fault cutout is set at 160°F.

4. On typical air conditioning applications, compressor superheat should be 12 - 15°F.

5. Helical coil springs used in reciprocating compressor suction and discharge valve assemblies should be replaced every 5,000 hours when used on normal chilled water (40° - 50°F LWT) air

conditioning applications. Other applications that may operate at higher-pressure ratios such as low temp brine (20 - 39°F LWT), and units operating under high ambient conditions (ambient temps

above 115°F) should have more frequent maintenance intervals.

10

Loading...

Loading...