Operation Manual / 4 Product description / A130-M.. - A145-M..

Page 29 /

© Copyright 2017 ABB. All rights reserved.

4 Monitoring operation

4.1 Oil pressure, oil temperature

Lubricating oil pressure, oil inlet

To limit the oil flow rate through the turbocharger to the admissible values with the engine at

full load, an oil orifice is mandatory or already fitted at the oil inlet of the bearing casing if the

oil inlet pressure is > 3 bar.

Assuring lubricating oil pressure

Serious damage to engine or property can result from missing or insufficient

lubricating oil supply.

The lubricating oil pressure must be monitored during operation and the

necessary pressure assured at the oil inlet.

Pressure at oil inlet upstream of orifice

[bar]

Normal operation 2.0 < p

oil

≤ 4.5

Engine start: Cold oil, admissible for maximal 15 minutes

Engine idling, admissible for maximal 1 hour 0.5 < p

oil

≤ 2.5

Pre-lubrication and post-lubrication (engine stopped)

oil

Warning signal: (n ≥ 0.5 x n

Bmax

) < 1.25

Alarm signal: Not admissible. Stop the engine immediately. < 0.6

Table 6: Lubricating oil pressure, oil inlet

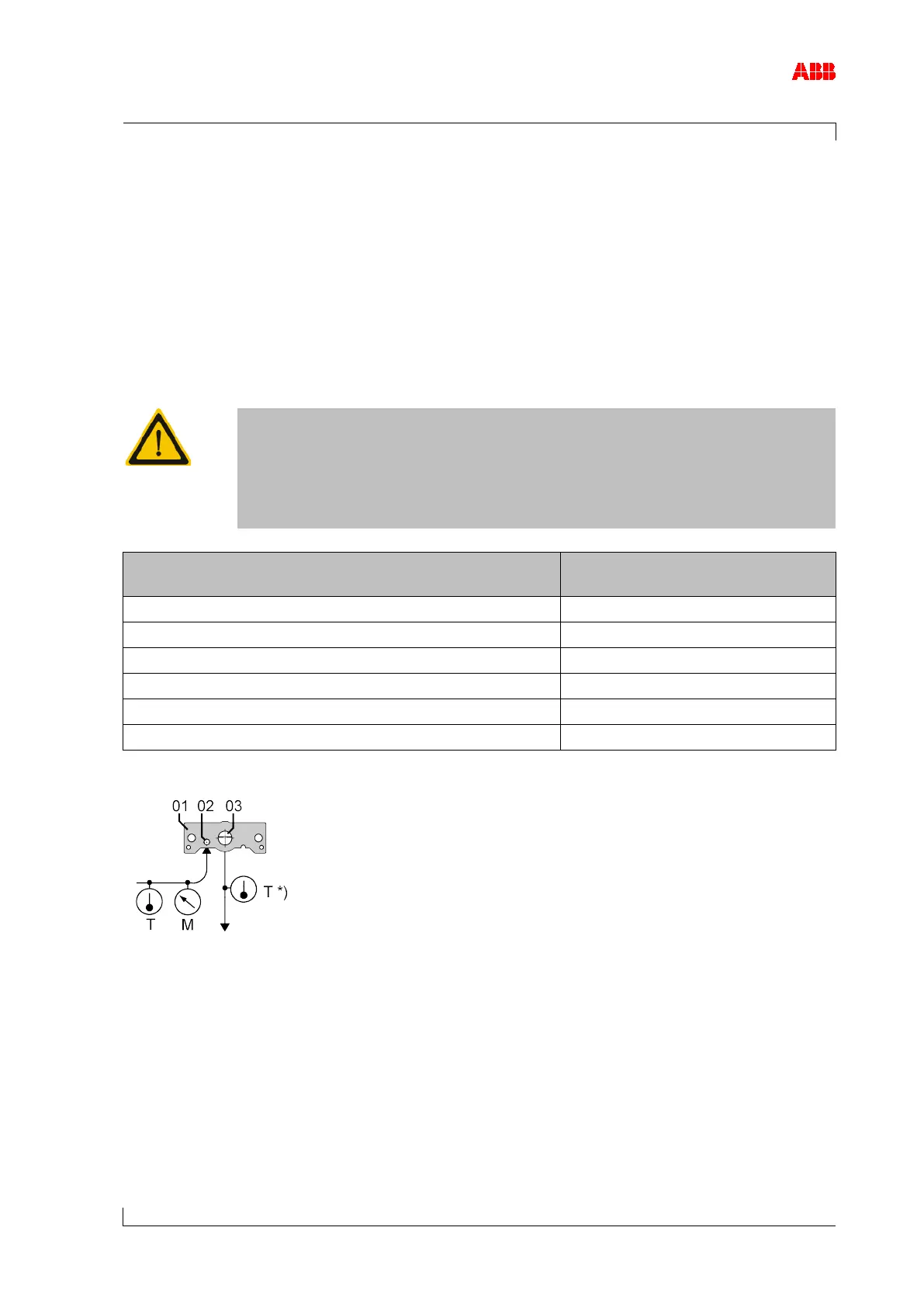

Turbocharger contact surface

Oil pressure measuring point

Oil temperature measuring point

For monitoring the lubricating oil pressure, ABB Turbo Systems recommends installing an "M"

manometer immediately before the turbocharger. If the pressure is controlled electronically,

the appropriate signals are to be triggered at the warning and alarm values.

*) If the drain pipe is vented, the measuring point for lubricating oil temperature can be in-

stalled at the outlet in the vent tank. Otherwise the measurement should be taken in the drain

pipe as close to the turbocharger as possible.

Loading...

Loading...