Operation Manual / 4 Product description / A130-M.. - A145-M..

Page 41 /

© Copyright 2017 ABB. All rights reserved.

5.3 Expected replacement intervals

Rotating components

The recommended replacement intervals for compressor and turbine wheels are specified

based on the safety concept for rotating parts (SIKO) and dependent on the operating condi-

tions. These intervals are shown on the rating plate of the turbocharger.

Depending on the system-specific operating conditions, a differentiation must be made be-

tween the intervals to be expected for:

replacing the bearing parts and

replacing the non-rotating components exposed to hot gas.

A decisive role is played by various influencing parameters which, in extreme cases, can dras-

tically shorten the replacement interval of these parts.

During the prescribed periodic service work, the individual parts are examined for wear and

replaced if necessary.

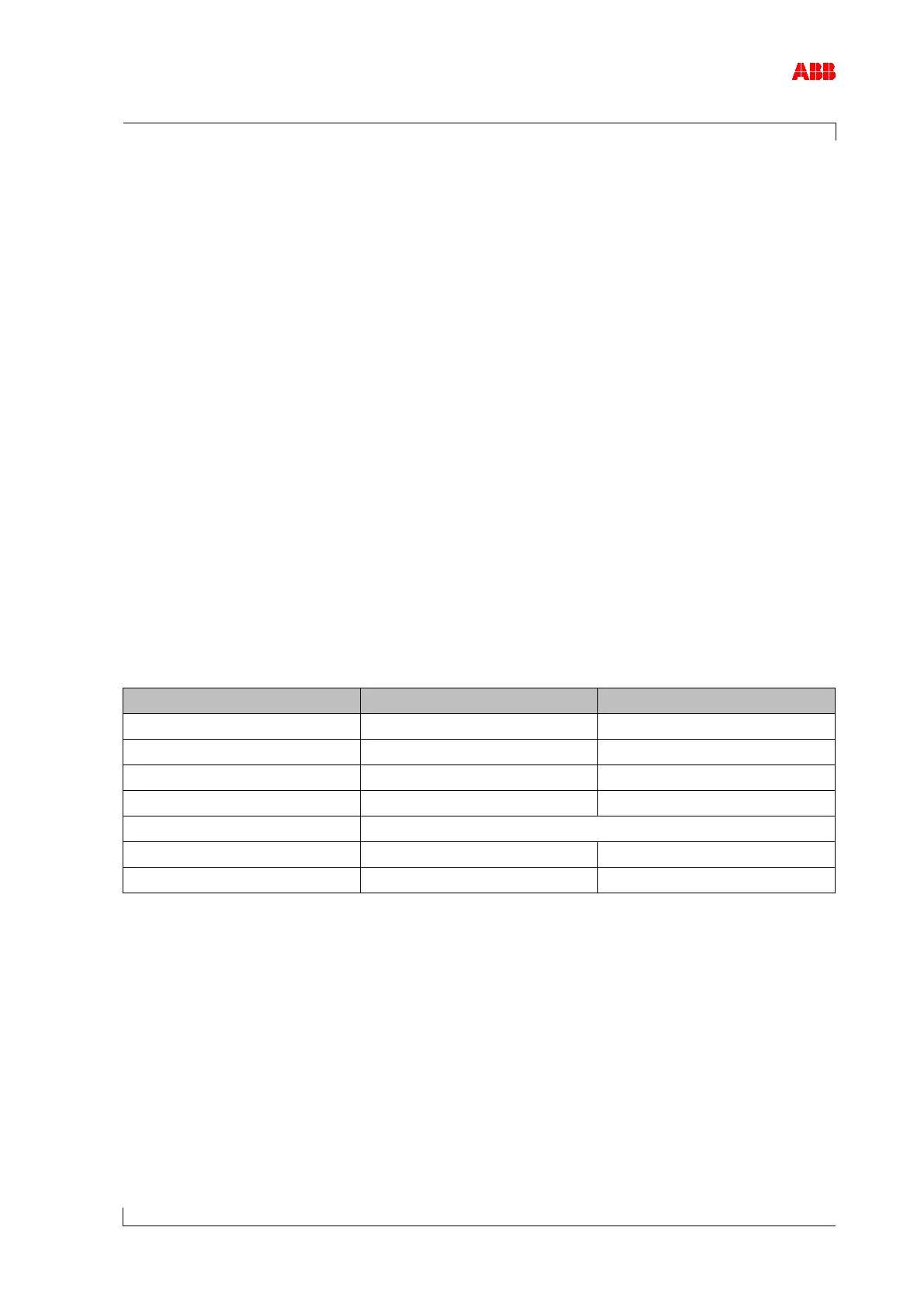

Expected replacement intervals [h]

Turbine casing 25000 … 50000 25000 … 50000

Nozzle ring 25000 … 50000 10000 … 25000

Gas outlet flange 25000 … 50000 25000

Heat shield 25000 … 50000 25000

Rotor components See rating plate data

Bearing parts 12000 … 24000 12000 … 24000

Other casings 50000 50000

Table 10: Expected replacement intervals

The specified values are guideline values and not guaranteed values, see Influencing parame-

ters.

Loading...

Loading...