Required equipment

NoteArt. no.Equipment, etc.

Detailed in section Standard

tools on page 351.

-Standard toolkit

These procedures include refer-

ences to the tools required.

Other tools and procedures may be

required. See references to these

procedures in the step-by-step instruc-

tions below.

See chapter Circuit diagrams

on page 357.

Circuit diagram

Inspecting cable harness, axes 1-6

Use this procedure to inspect cable harness of axes 1-6.

NoteAction

DANGER

Turn off all:

• electric power supply

• hydraulic pressure supply

• air pressure supply

to the robot, before entering the robot working

area.

1

Make an overall inspection of the cable har-

ness in order to detect wear and damage.

2

Shown in figure Location of cable har-

ness, axes 1-6 on page 114

Check the connectors at the base.3

Shown in figure Location of cable har-

ness, axes 1-6 on page 114.

Check the motor cables.4

Shown in figure Location of cable har-

ness, axes 1-6 on page 114.

Check the cable guide axis 2.

Replace if damaged.

5

Shown in figure Location of cable har-

ness, axes 1-6 on page 114

Check the metal clamps on the lower arm.6

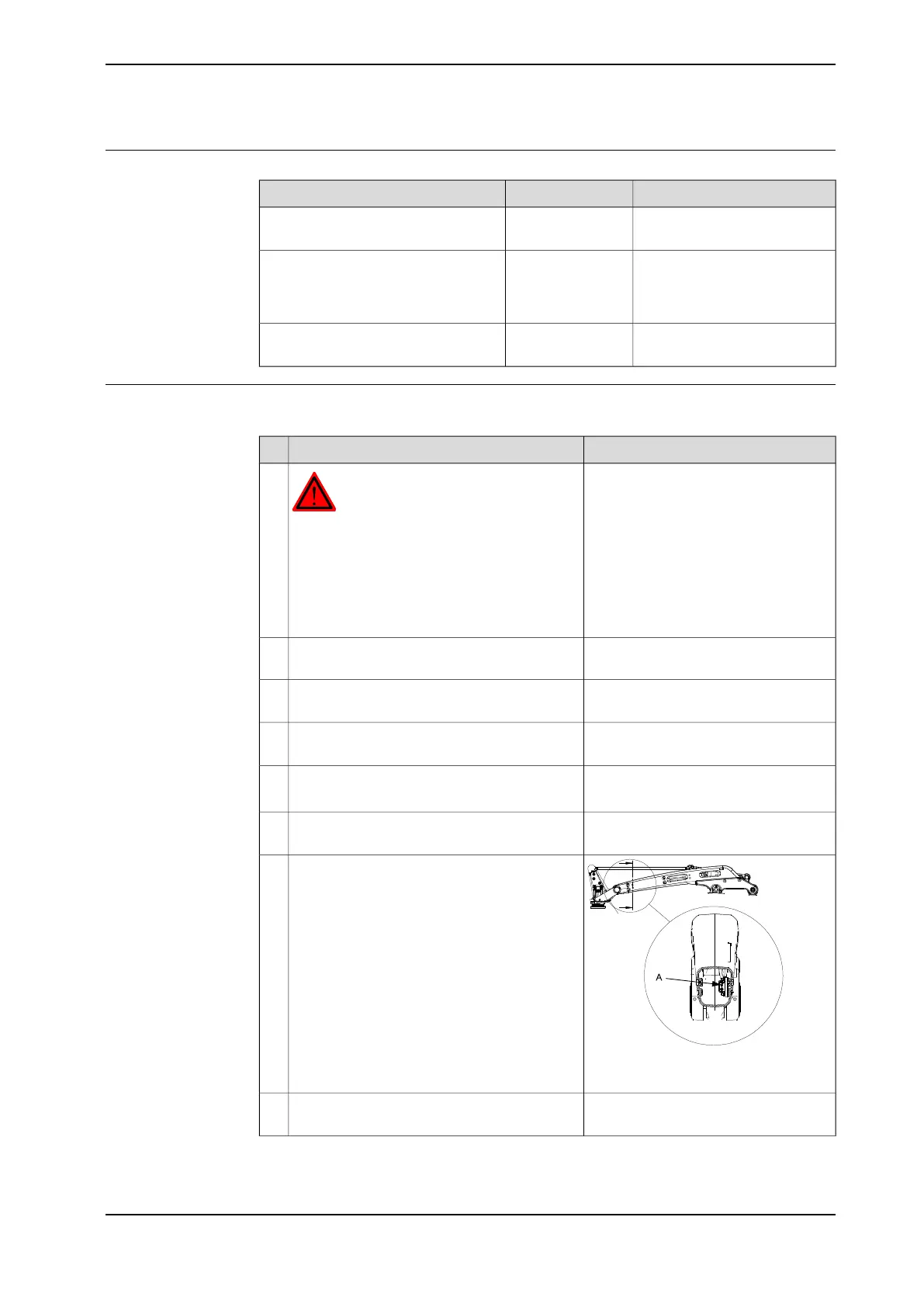

xx0500002498

Check the metal clamps holding the cable

harness inside the upper arm, as shown in

figure to the right.

7

A: Metal clamp inside upper arm

Shown in figure Location of cable har-

ness, axes 1-6 on page 114.

Check the metal clamp holding the motor cable

on axis 6.

8

Continues on next page

3HAC039838-001 Revision: C 115

© Copyright 2013 ABB. All rights reserved.

3 Maintenance

3.3.5 Inspecting, cable harness

Continued

Loading...

Loading...