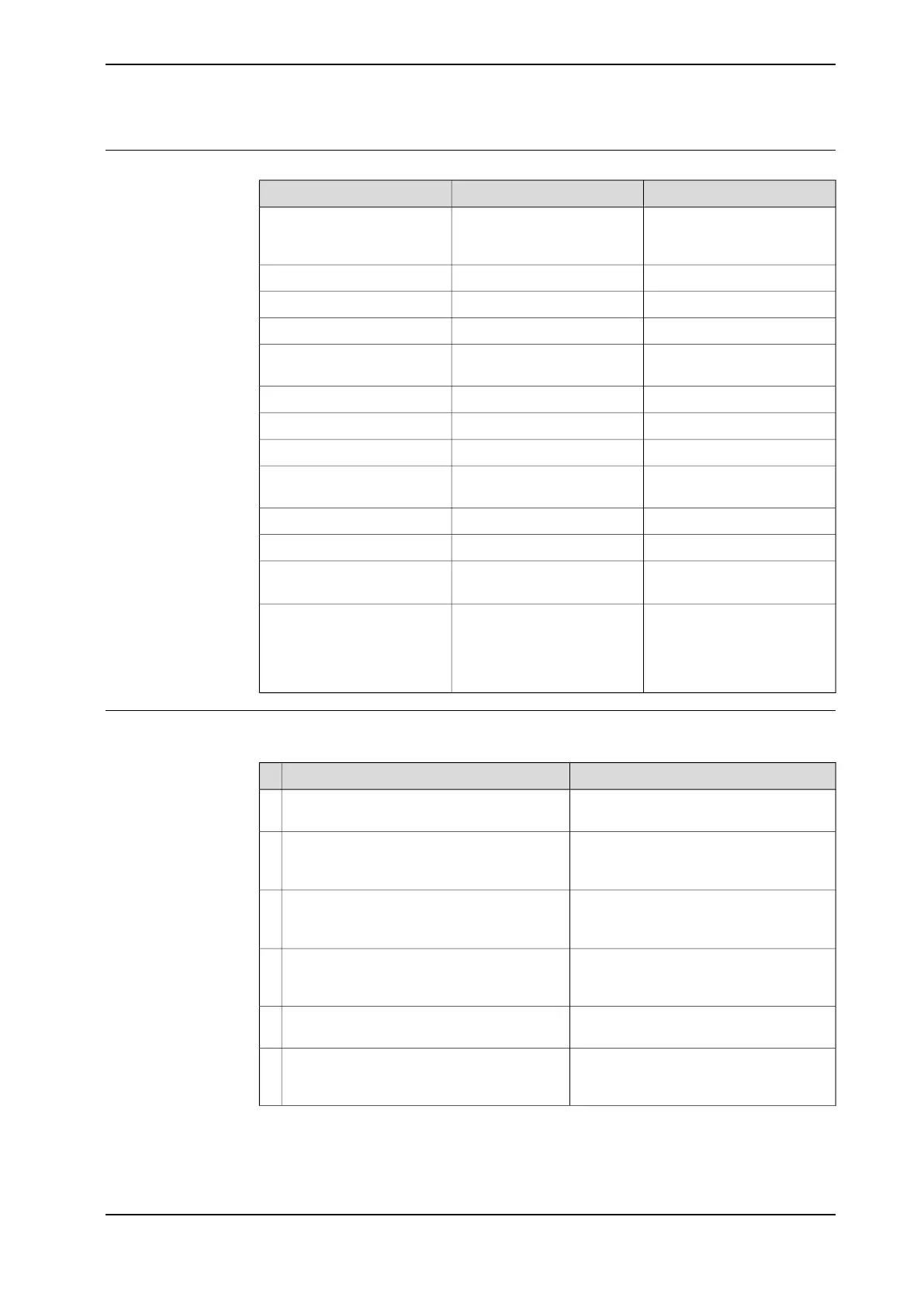

Required equipment

NoteArt.no.Equipment, etc.

Includes:

• 3HAC037314-001

bushing (2 pcs)

For spare part no. see:

• Spare parts on page 355

Upper arm, axis 4

Conical roller bearing3HAC039571-002Grease filling tool

Optimol Longtime PD 23HAC9408-1Bearing grease

Mercasol 31063HAC034903-001Rust preventive

For information how to use

the tool, please contact ABB.

3HAC038174-002Shaft fitting/removing tool

T=2.5 mm3HAC038174-031Shims

Range: Up to 400 mm.-Slide caliper (large size)

0.4 mm-Feeler gage

For cleaning surface of bush-

ing

-Isopropanol

-Glycerine

Loctite 2433HAB7116-1Locking liquid

Content is defined in section

Standard tools on page 351.

-Standard toolkit

These procedures include

references to the tools re-

quired.

Other tools and procedures

may be required. See refer-

ences to these procedures in

the step-by-step instructions

below.

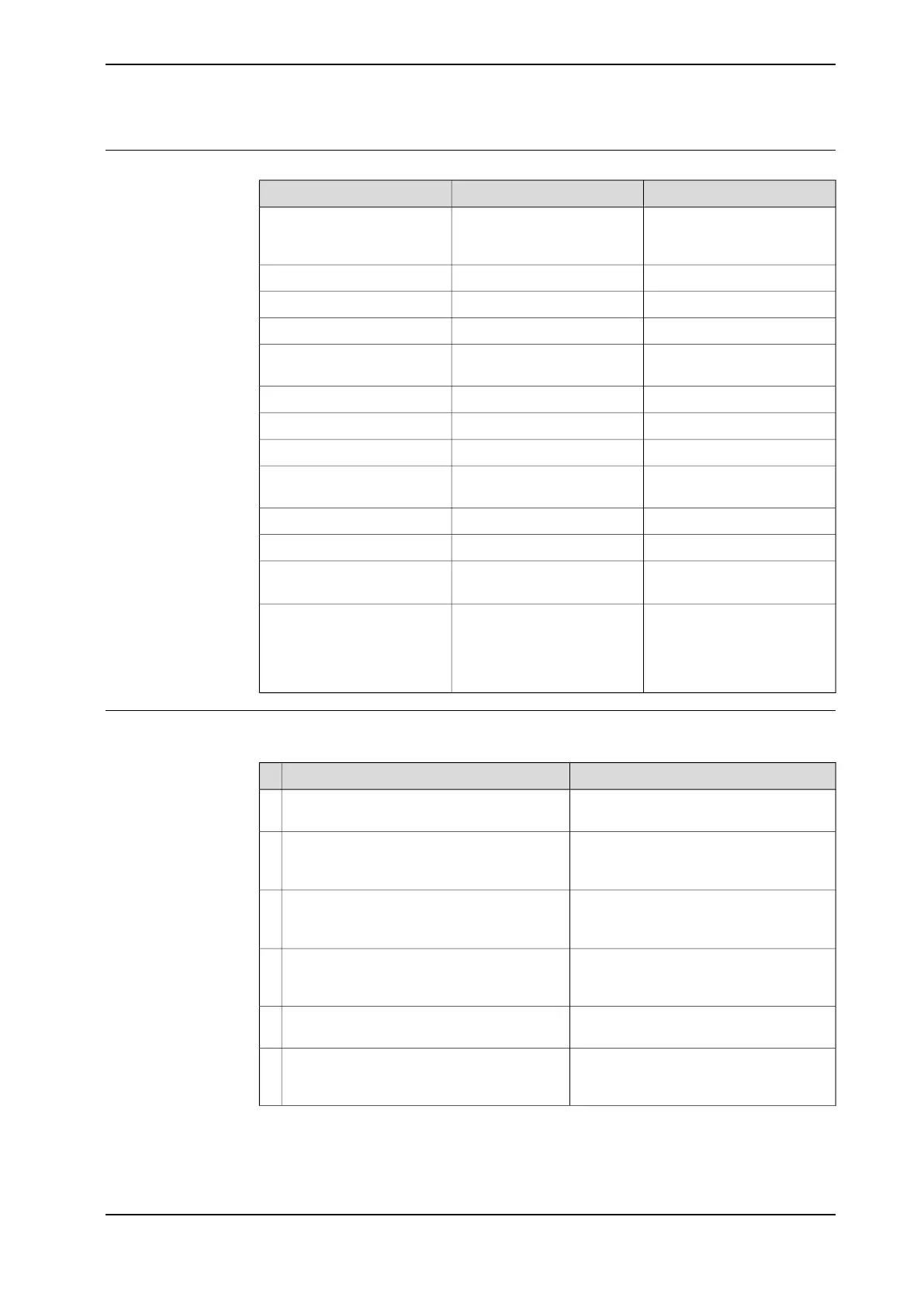

Removing the upper arm

Use this procedure to remove the upper arm.

NoteAction

Remove all equipment fitted to upper arm

and tilthouse unit.

1

Shown in the figure:

• Calibration scale and correct axis

position on page 332

Move the robot to calibration position.2

See section:

• Replacing the balancing device on

page 265

Remove the balancing device.3

Put two loading pallets under the balancing

weight and run axis 3 så that the balancing

weight rests on the pallets.

4

Release the brake of axis 3 so that the balan-

cing weight really rests on the pallets.

5

Move the lower arm forward to get a better

mounting position in the continued removal

procedure.

6

Continues on next page

3HAC039838-001 Revision: C 211

© Copyright 2013 ABB. All rights reserved.

4 Repair

4.4.3 Replacing the upper arm

Continued

Loading...

Loading...