107

FEM630 | ELECTROMAGNETIC FLOWMETER | OI/FEM630-EN REV. A

8 ...Operation

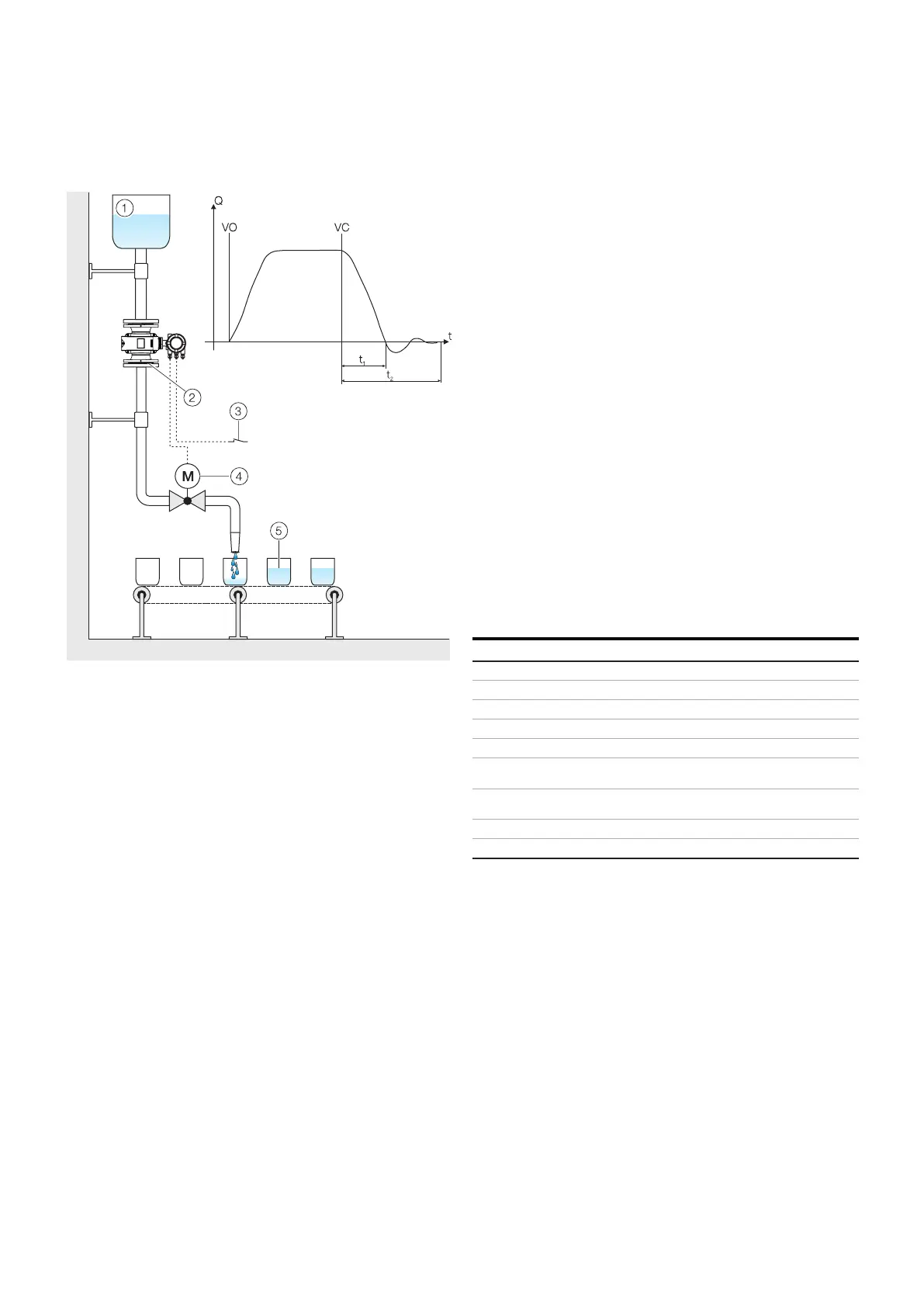

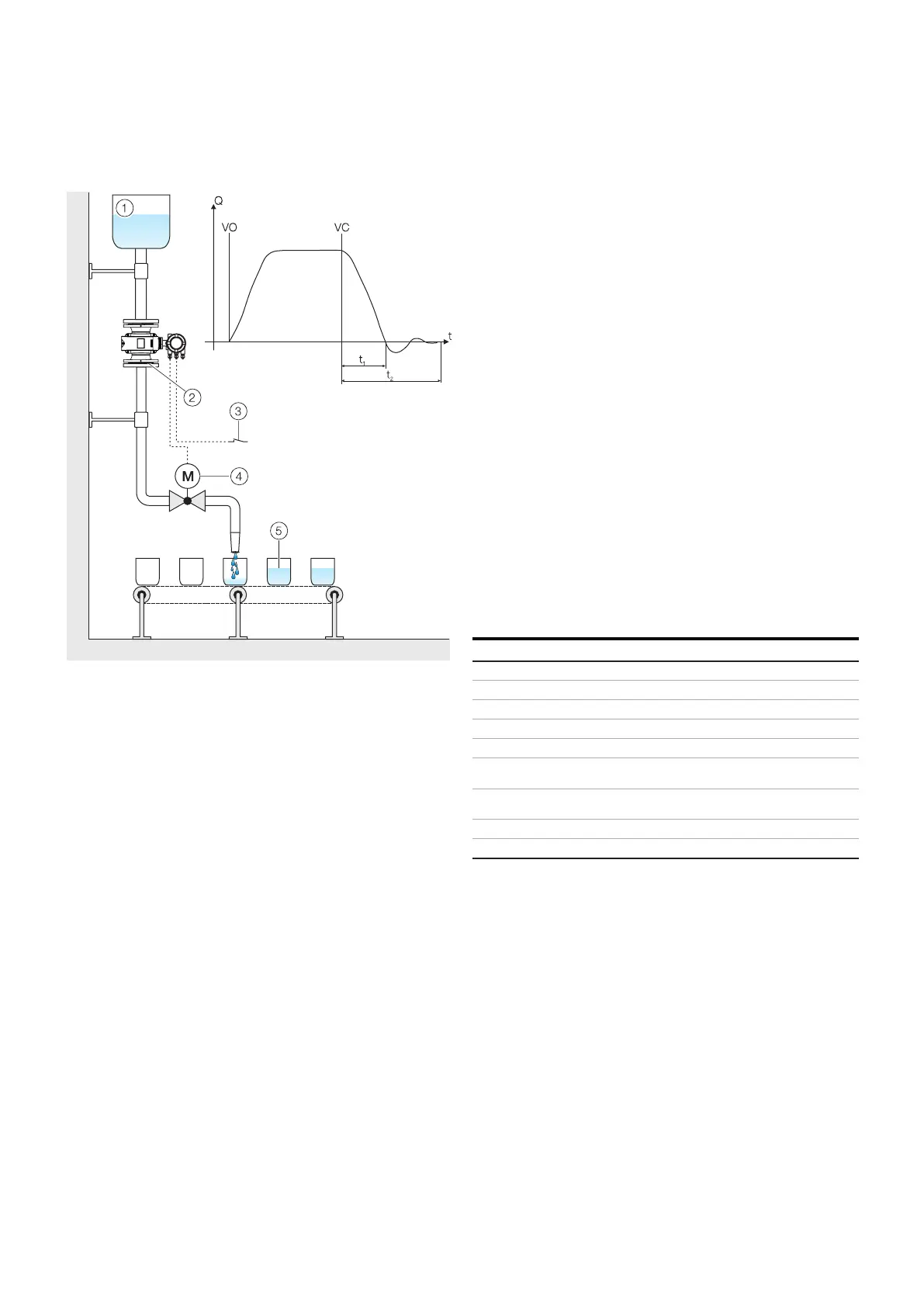

Filling function

Menu / parameter Description

Mode Pulse

Outp. Flow Direction Forward

Input/Output / ...Setup Pulse Output

Output Value Pulse Pulse Volume Flow

Pulses per Unit

Setting in accordance with

requirement

Pulse Width

Setting in accordance with

requirement

Mode

Supply tank

Sensor

Start / stop fill operation (digital input through plug-in card)

Fill valve

Filling tank

Valve open (filling started)

Valve closed (fill quantity reached)

Valve closing time

Overrun time

1

2

3

4

5

VO

VC

t1

t2

Figure 69 FillMass fill function

The optional filling function allows filling with filling times> 3

seconds.

Filling quantity is configurable and the filling process can be

started via the digital input (plug-in card).

As soon as the filling quantity has been reached, the valve can

be closed via the digital output. Filling quantity correction is

calculated by measuring the overrun quantity. Additionally,

the low flow cut-off can be configured if required.

Setup

For the configuration of the fill function, the following steps

must be performed:

1 The fill function must be active. See also the ‘Device

Setup / ...Transmitter / ...Feature Settings / ...’ menu.

2 One digital output must be configured as a binary output

with the function ‘Batch End Contact’. See also the

‘Input/Output / ...’ menu. As an option, one digital input

(option module) can be configured with the function

‘Start/Stop Batching’ at the start of the filling process.

3 The parameters for the fill function must be configured.

See also the ‘Totalizer / ...Batching / ...’ menu.

Note

During fast filling processes, the damping should be set to

the minimum value to guarantee the greatest possible

accuracy of the fill quantity.

See also the ‘Device Setup / ...Transmitter / ...’ menu.

Brief overview of configurations

Configuration of digital output 41 / 42 as pulse output for

forward flow and digital output 51 / 52 as pulse output for

reverse flow.

Loading...

Loading...