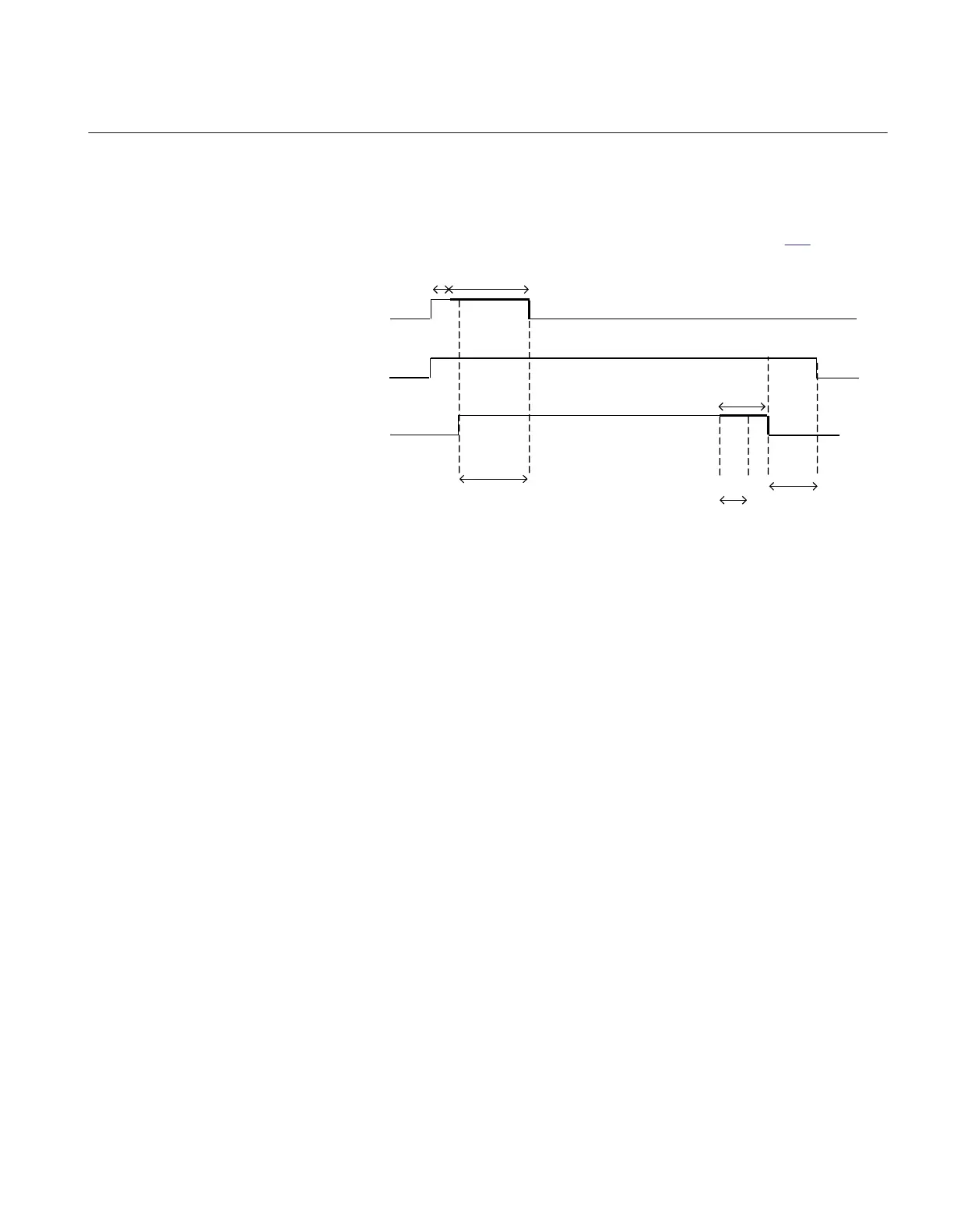

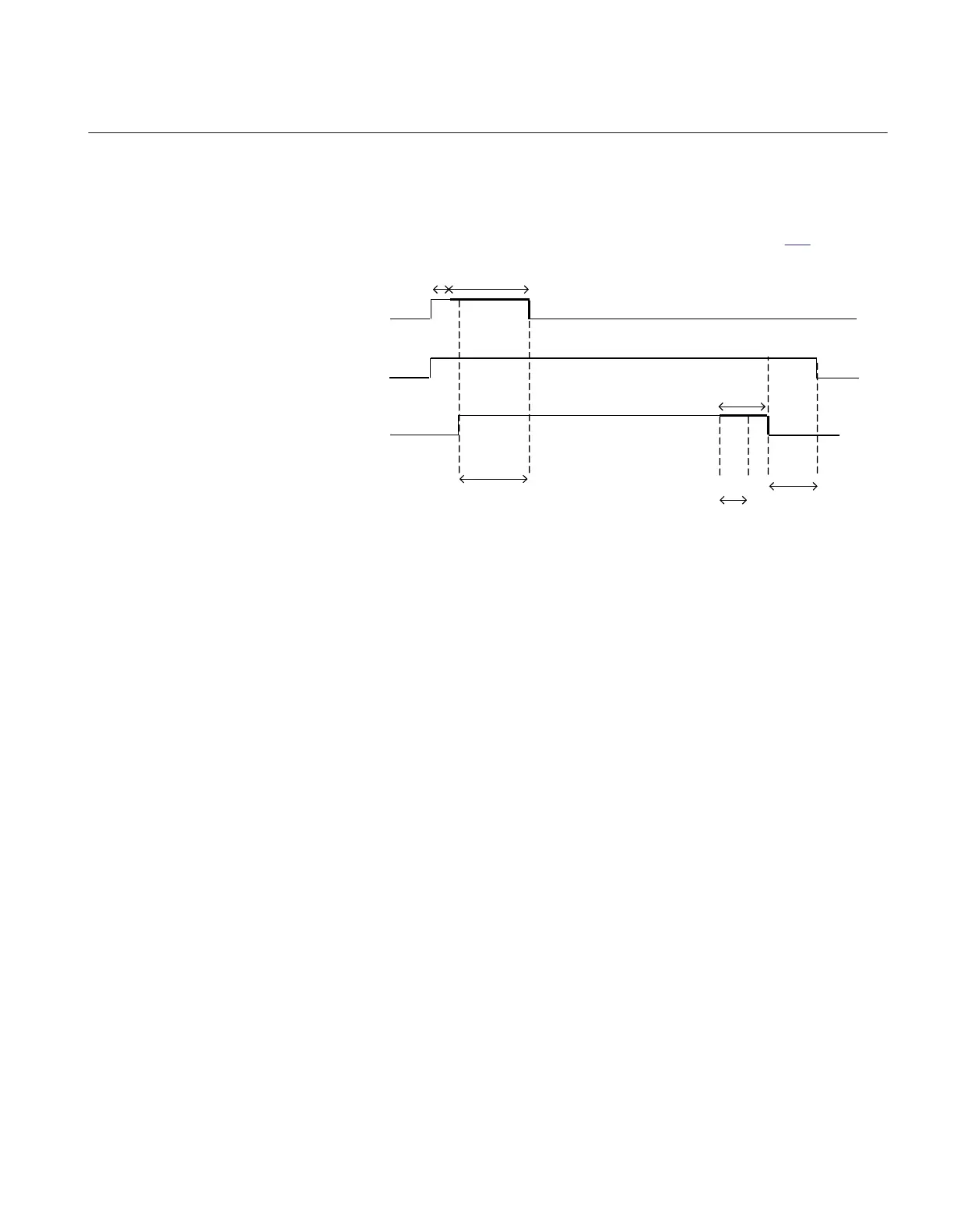

Usually the tap changer mechanism can give a signal, “Tap change in progress”, during

the time that it is carrying through an operation. This signal from the tap changer

mechanism can be connected via a BIM module to TCMYL

TC (84) or TCLYLTC (84)

input TCINPROG, and it can then be used by TCMYLTC (84) or TCLYLTC (84)

function in three ways, which is explained below with the help of figure

180.

VRAISE/VLOWER

tTCTimeout

TCINPROG

a

h

d

e f

g

cb

en06000482_ansi.vsd

ANSI06000482 V1 EN-US

Figure 180: Timing of pulses for tap changer operation monitoring

pos Description

a Safety margin to avoid that TCINPROG is not set high without the simultaneous presence of an

VRAISE or VLOWER command.

b Time setting

tPulseDur

.

c Fixed extension 4 sec. of

tPulseDur

, made internally in TCMYLTC (84) or TCLYLTC (84) function.

d Time setting

tStable

e New tap position reached, making the signal “tap change in progress” disappear from the tap

changer, and a new position reported.

f The new tap position available in TCMYLTC (84) or TCLYLTC (84).

g Fixed extension 2 sec. of TCINPROG, made internally in TCMYLTC (84) or TCLYLTC (84) function.

h Safety margin to avoid that TCINPROG extends beyond

tTCTimeout

.

The first use is to reset the Automatic voltage control for tap changer function

TR1A

TCC (90) for single control and

TR8ATCC (90) for parallel control as soon as

the signal TCINPROG disappears. If the TCINPROG signal is not fed back from the

tap changer mechanism, TR1ATCC (90) or TR8ATCC (90) will not reset until

tTCTimeout has timed out. The advantage with monitoring the TCINPROG signal in

this case is thus that resetting of TR1ATCC (90) or TR8ATCC (90) can sometimes be

made faster, which in turn makes the system ready for consecutive commands in a

shorter time.

1MRK 511 401-UUS A Section 14

Control

Bay control REC670 2.2 ANSI 441

Application manual

Loading...

Loading...