TCS-Compact 6 Putting into operation

EN - 17

You can activate the device manually via the cover in order to set the dosing of the anti-adhesives.

• An injection pulse is activated by lightly pressing down the cover.

• You can assess the amount of the atomized anti-spatter by the produced spray mist.

• The injection pulse should only be activated for max. 2 sec.

• You can increase or reduce the amount of anti-spatter via the adjusting screw (8) (see Fig. 11 Adjusting

the anti-spatter fluid on page EN-16).

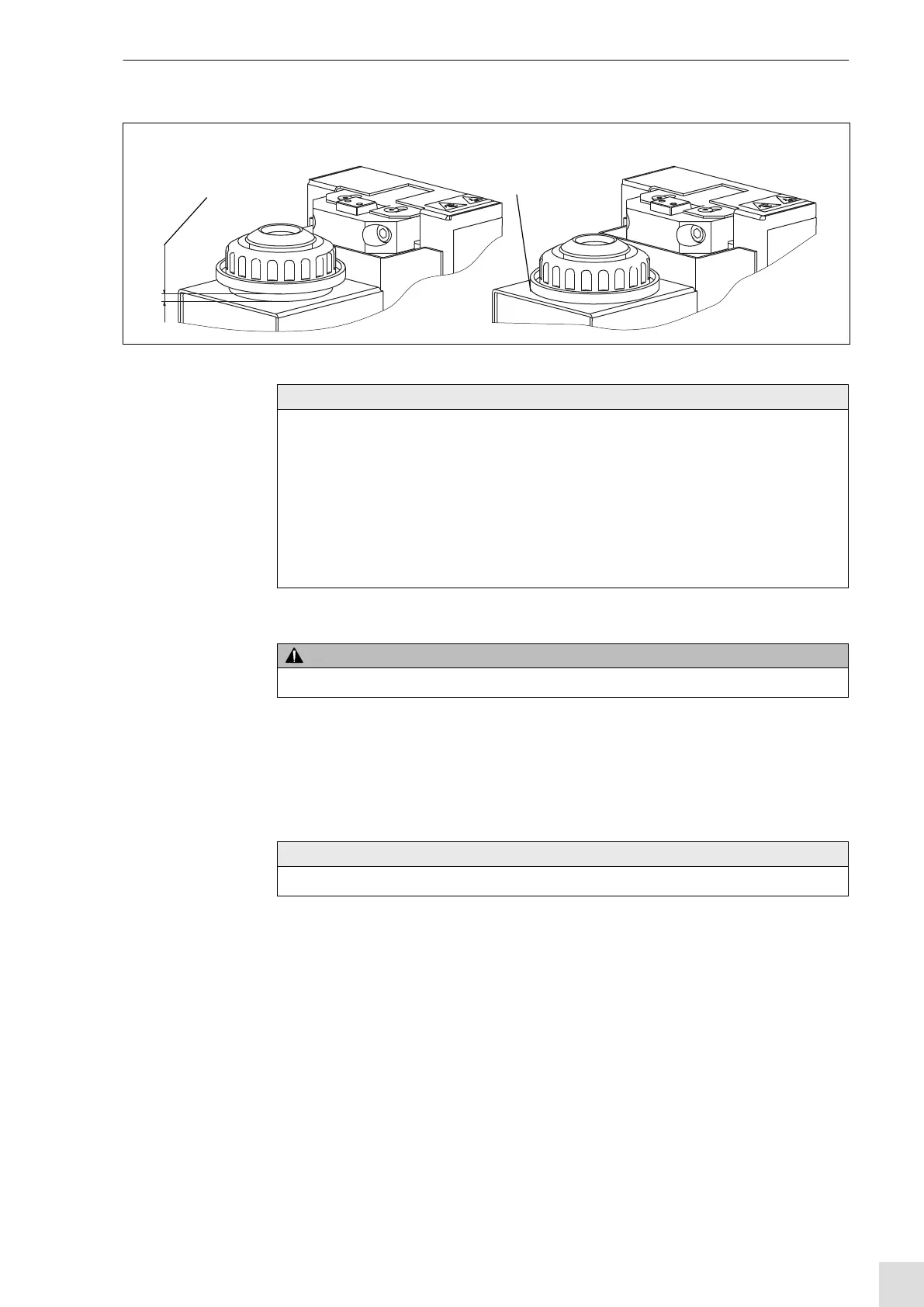

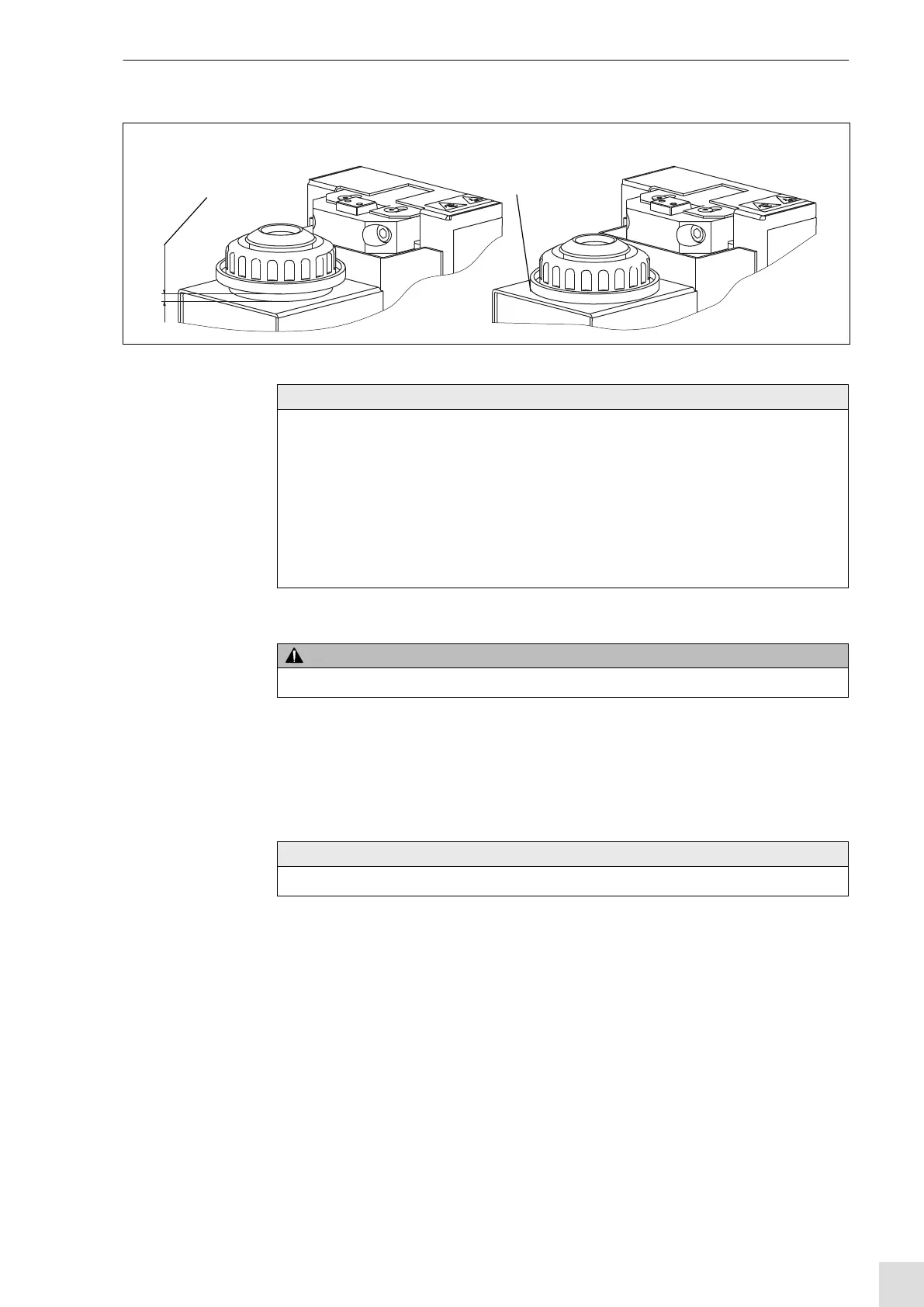

Fig. 12 Stroke movement injection unit

Injection unit not activated

(max. stroke movement)

max. 6 mm

Injection unit

activated

NOTE

• Observe the max. stroke movement for injection.

• The max. stroke travel (traverse movement of the welding torch) should not exceed 6 mm.

• We recommend a maximum injection impulse of 3 s.

The injection pulse is reset when moving out of the injection unit.

• Use the adjusting screw (8) to adjust the amount of anti-adhesives per injection impulse (see Fig.

11 Adjusting the anti-spatter fluid on page EN-16).

• The residual oil of the anti-spatter from the injection unit is collected in the drain bottle (7) (see Fig.

11 Adjusting the anti-spatter fluid on page EN-16) and can be reused after cleaning particulate from

it.

CAUTION

• When setting the anti-spatter adjustment manually, wear safety goggles.

NOTE

• A small amount of anti-spatter is sufficient to achieve the desired effect.

Loading...

Loading...