26 American Dryer Corp. 112144-46

2. Technical Gas Data

a. Gas Specifications

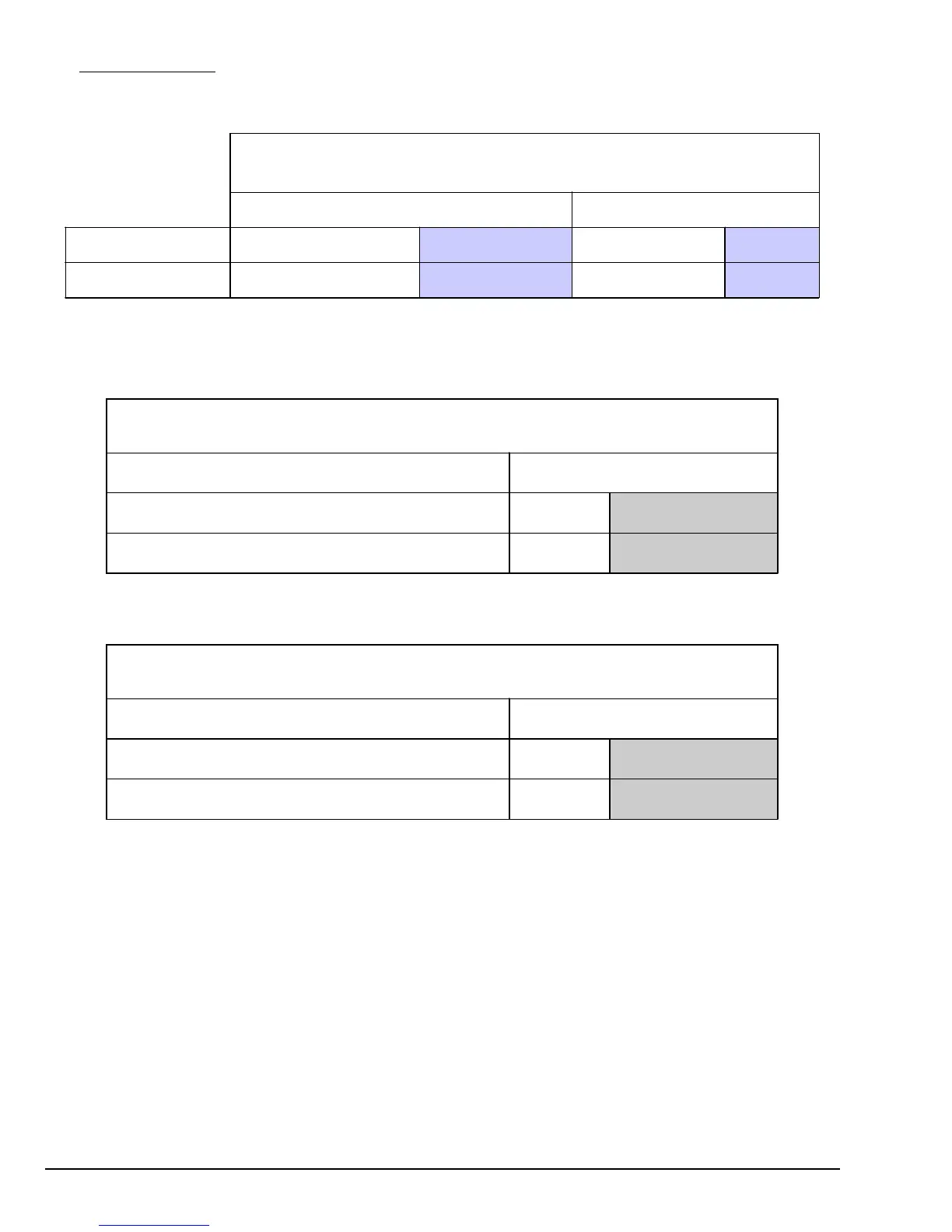

ADG-320D

Gas Inlet Size (each basket/tumbler) 1/2” N.P.T.

Btu/hr Input (each basket/tumbler) 60,000 15,120 kcal/hr

Btu/hr Input (total for both baskets/tumblers) 120,000 30,240 kcal/hr

N.P.T. = National Pipe Thread

ADG-330D

Gas Inlet Size (each basket/tumbler) 1/2” N.P.T.

Btu/hr Input (each basket/tumbler) 68,000 17,136 kcal/hr

Btu/hr Input (total for both baskets/tumblers) 136,000 34,272 kcal/hr

N.P.T. = National Pipe Thread

TYPE OF GAS

NATURAL LIQUID PROPANE

Manifold Pressure* 3.5 inches W.C. 8.7 mb 10.5 inches W.C. 26.1 mb

In-Line Pressure 6.0 - 12.0 inches W.C. 14.92 - 29.9 mb 11.0 inches W.C. 27.4 mb

Shaded areas are stated in metric equivalents

b. Natural Gas

Regulation is controlled by each gas valve’s internal regulator. Incoming supply pressure must be consistent

between a minimum of 6.0 inches (14.92 mb) and a maximum of 12.0 inches (29.9 mb) water column

(W.C.) pressure.

c. Liquid Propane (L.P.) Gas

Dryers made for use with L.P. gas have the gas valve’s internal pressure regulator blocked open so that the

gas pressure must be regulated upstream of the dryer. The pressure measured at each gas valve pressure tap

must be a consistent 10.5 inches (26.1 mb) water column. There is no regulator or regulation provided in

an L.P. dryer. The water column pressure must be regulated at the source (L.P. tank) or an external regulator

must be added to each dryer.

* Measured at gas valve pressure tap when gas valve is on.

Loading...

Loading...