HI ROLLER - BELT CONVEYORS 7. MAINTENANCE

HI ROLLER, MINI ROLLER, LO ROLLER & HI LIFE 7.2. BELT TRACKING GUIDE

P115506 R3 87

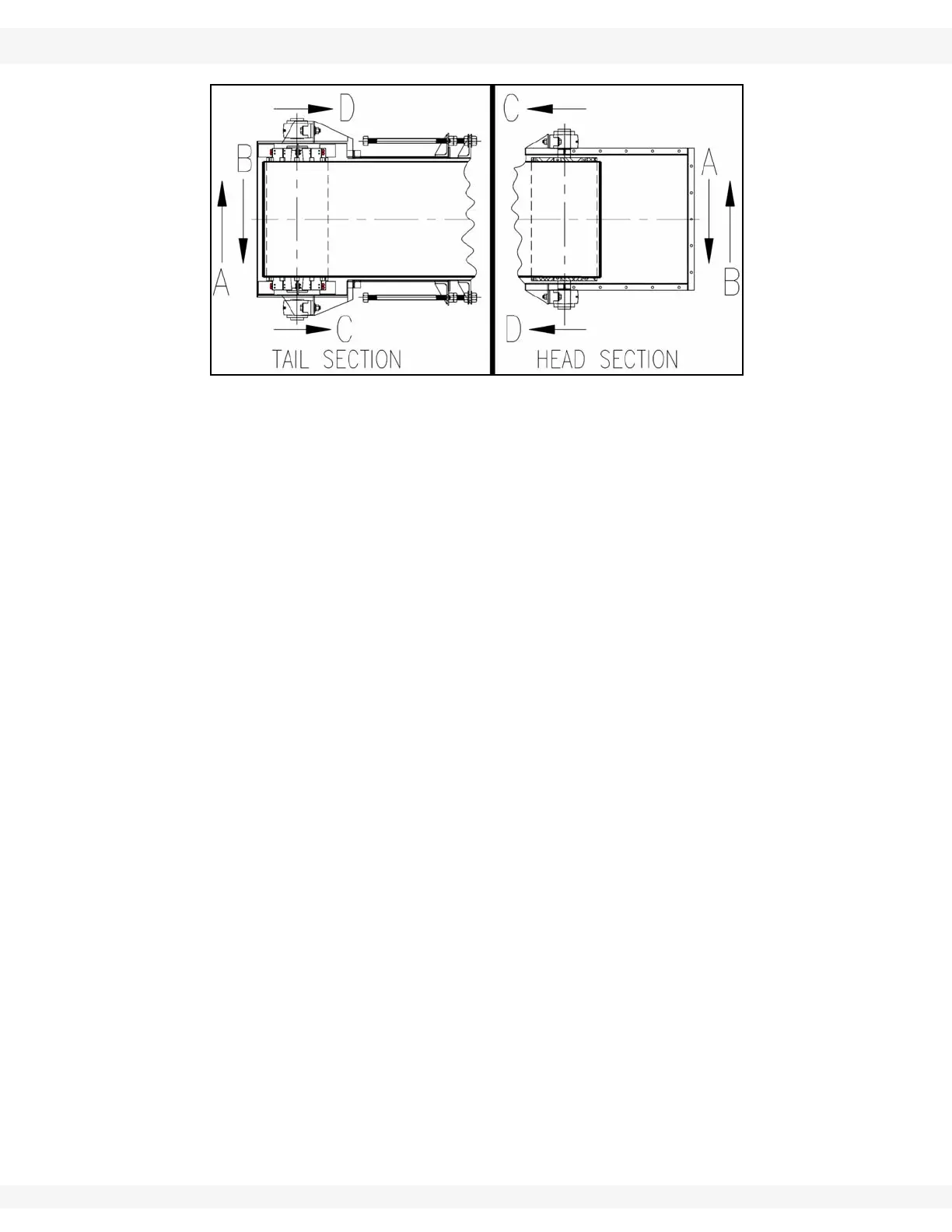

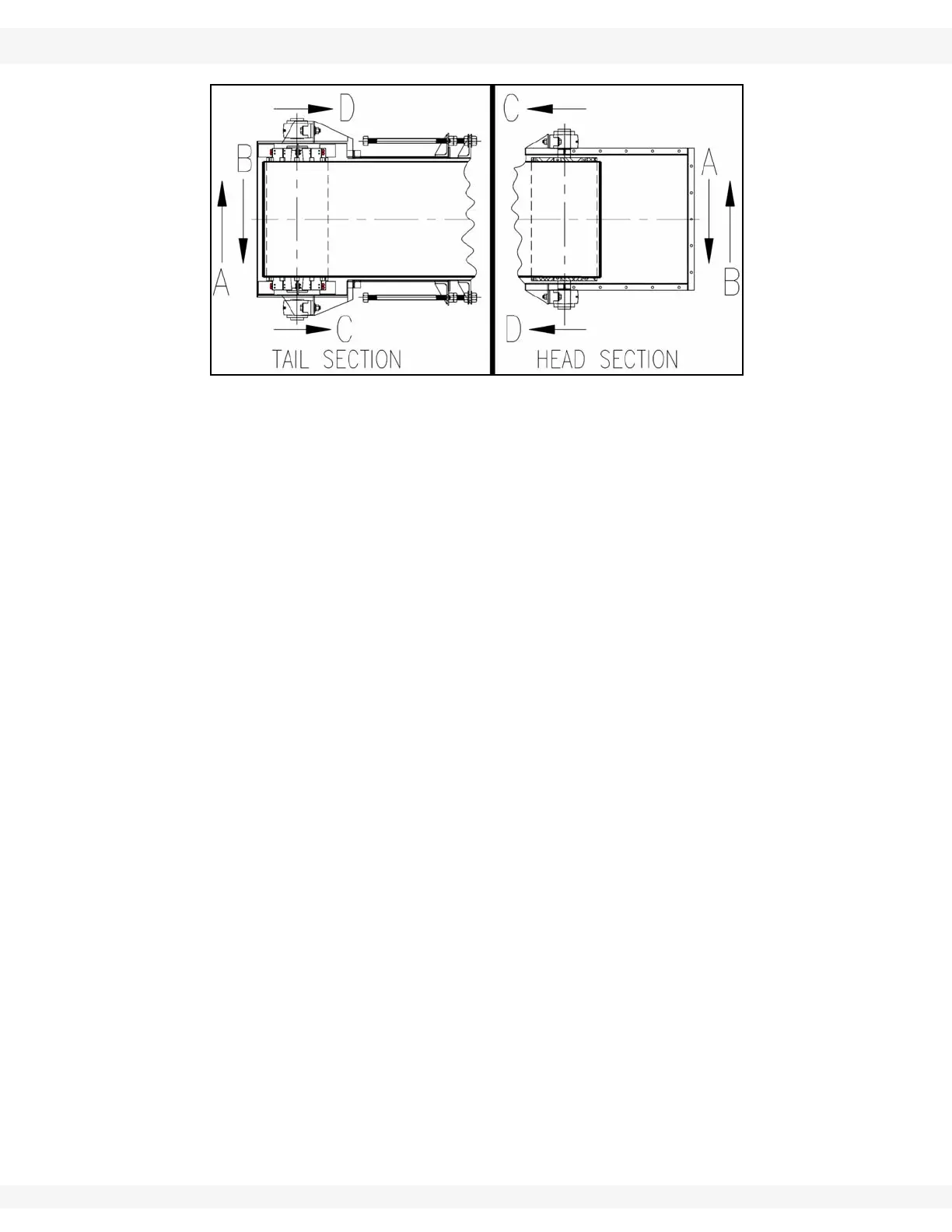

Figure 7.2

3. If the belt will not train after all of these procedures, thoroughly check that the

trunking, tripper, head and tail sections are square, level, and straight, and

that the belt splice is square, the belt is running of the flat part of the idler, and

that the load is centered. If nothing helps, contact Hi Roller Conveyors.

4. If the belt trains significantly different when loaded vs. empty, contact Hi

Roller.

IDLERS

Idlers may be adjusted only if attempts to train the belt with the head and tail

pulleys have failed. The conveyor must be square, level, in-line, belt splice must

be square, belt must be running on the flat part of the idler, and the load must be

centered on the belt. All of these must check out before attempting to train the

belt with the idlers.

1. Hi Roller and Mini Roller idler adjustments are completed by loosening the

two bearing retainer bolts. This should be done on the bearing that is easiest

to work on. These bolts hold the bearings in place and are located on both

sides of the conveyor as shown in Figure 7.3. The nuts on the inside of the

conveyor are welded to a nut clip so that they will not have to be held in order

to loosen the bearing bolts.

2. After loosening these bolts, the end of the idler can be shifted either forward

or backward.

3. Adjust 5 - 10 idlers in the middle of the conveyor. Adjust these idlers about 1/

4" to 3/8".

• If the belt is too close to the side of the bearing being adjusted, move the

bearing toward the head section. If the belt is too close to the opposite

side, move the bearing toward the tail section.

Loading...

Loading...