7. MAINTENANCE HI ROLLER - BELT CONVEYORS

7.3. IDLER REPLACEMENT - HI ROLLER MODELS HI ROLLER, MINI ROLLER, LO ROLLER & HI LIFE

96 P115506 R3

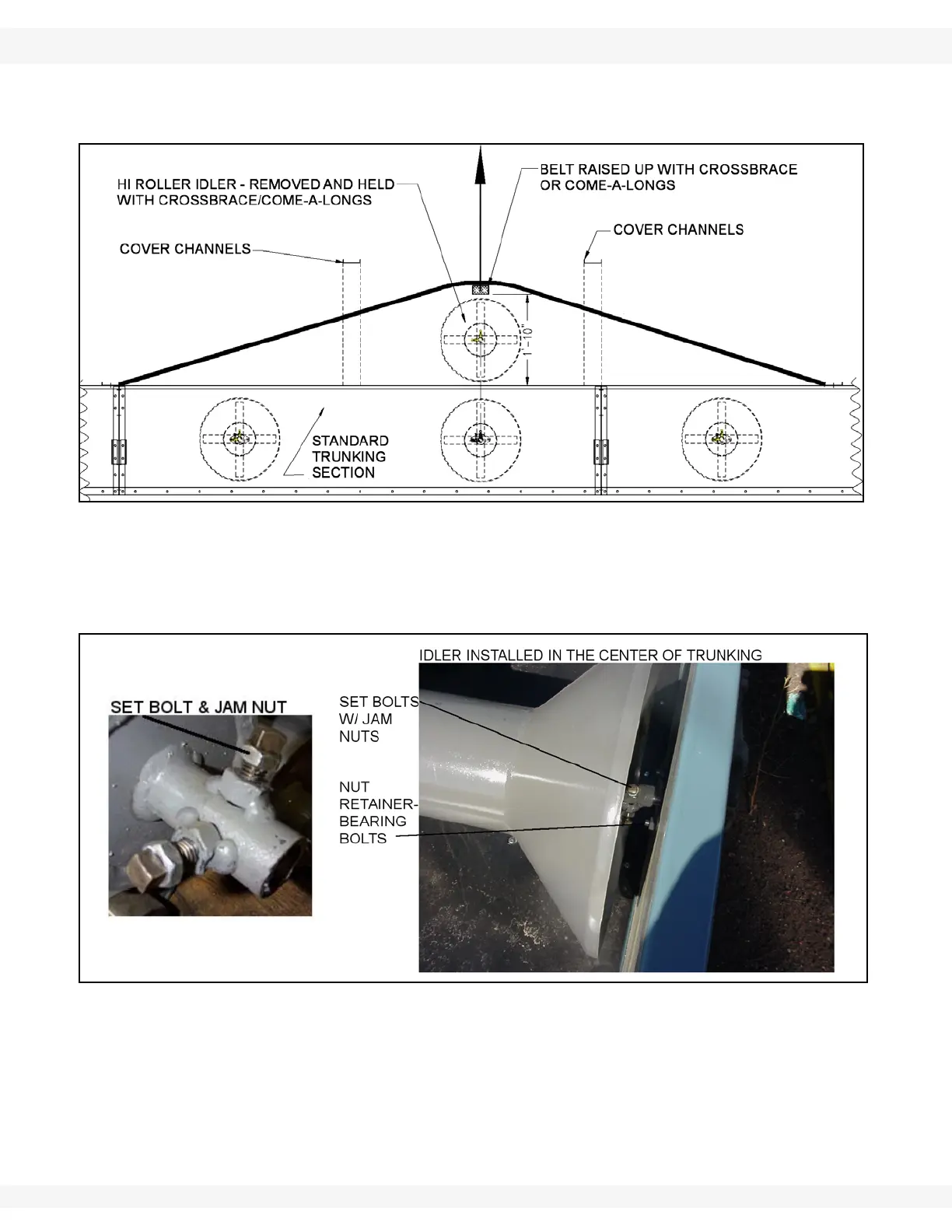

11. In some cases, the inlet/loader skirts, crossbraces, and other components

may have to be removed for proper clearance to replace the Hi Roller idler.

Figure 7.13

Note: The crossbrace and come-a-longs in Figure 7.13 are for Models 25-54 of the

larger Hi Roller idlers. Models 18 and 22 require a height opening of 1’8”.

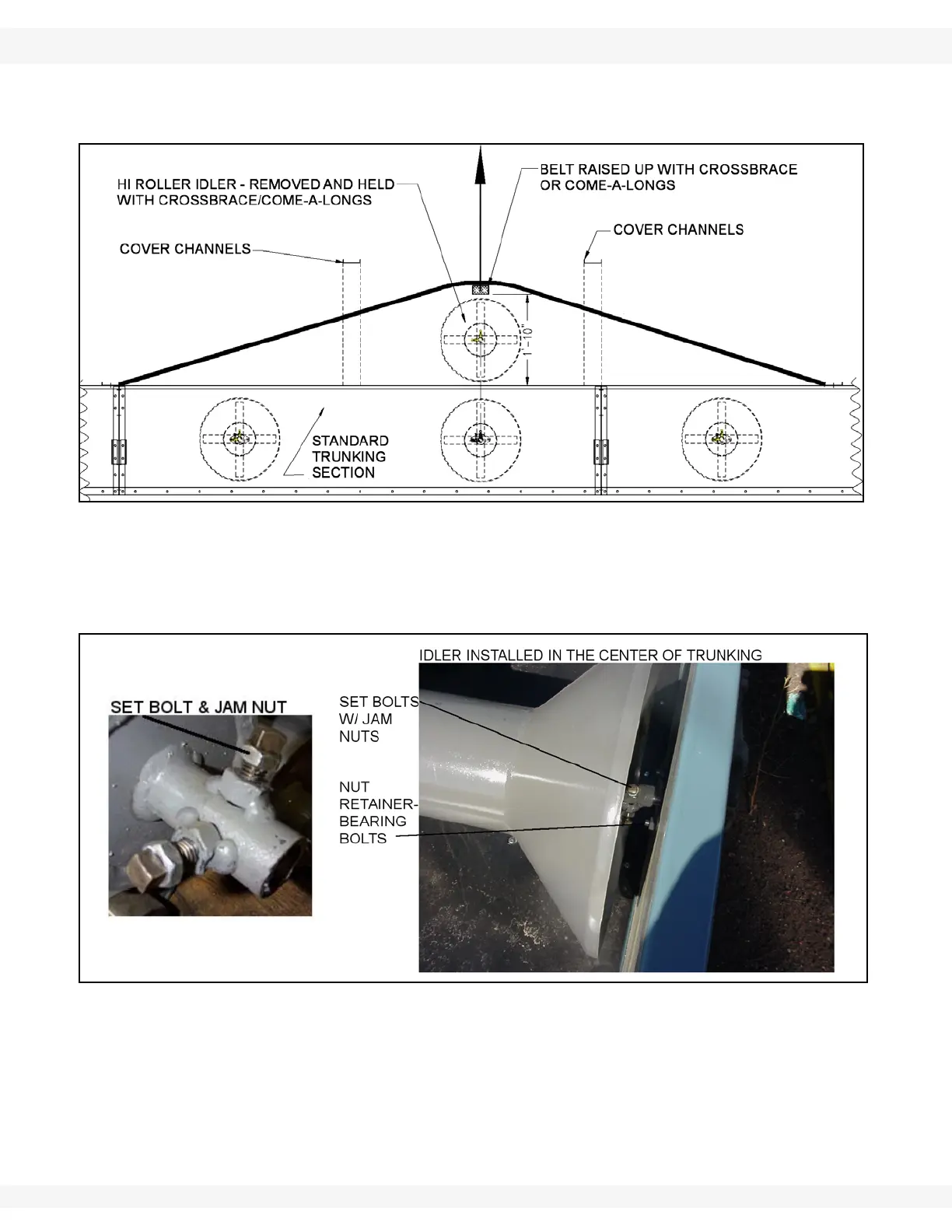

12. Loosen jam nut on set bolts on each side of the idler. See Figure 7.14.

Figure 7.14

13. Mark the location of the idler bearings on the sidewall of the trunking so that

the new idler bearings can be installed in the same location.

14. Loosen and remove bolts holding idler bearings in place.

a. Nut retainers on the inside of the trunking hold the nuts and therefore a

wrench is not required on the inside nut. See Figure 7.15.

Loading...

Loading...