320 Rockwell Automation Publication MOTION-RM003I-EN-P - February 2018

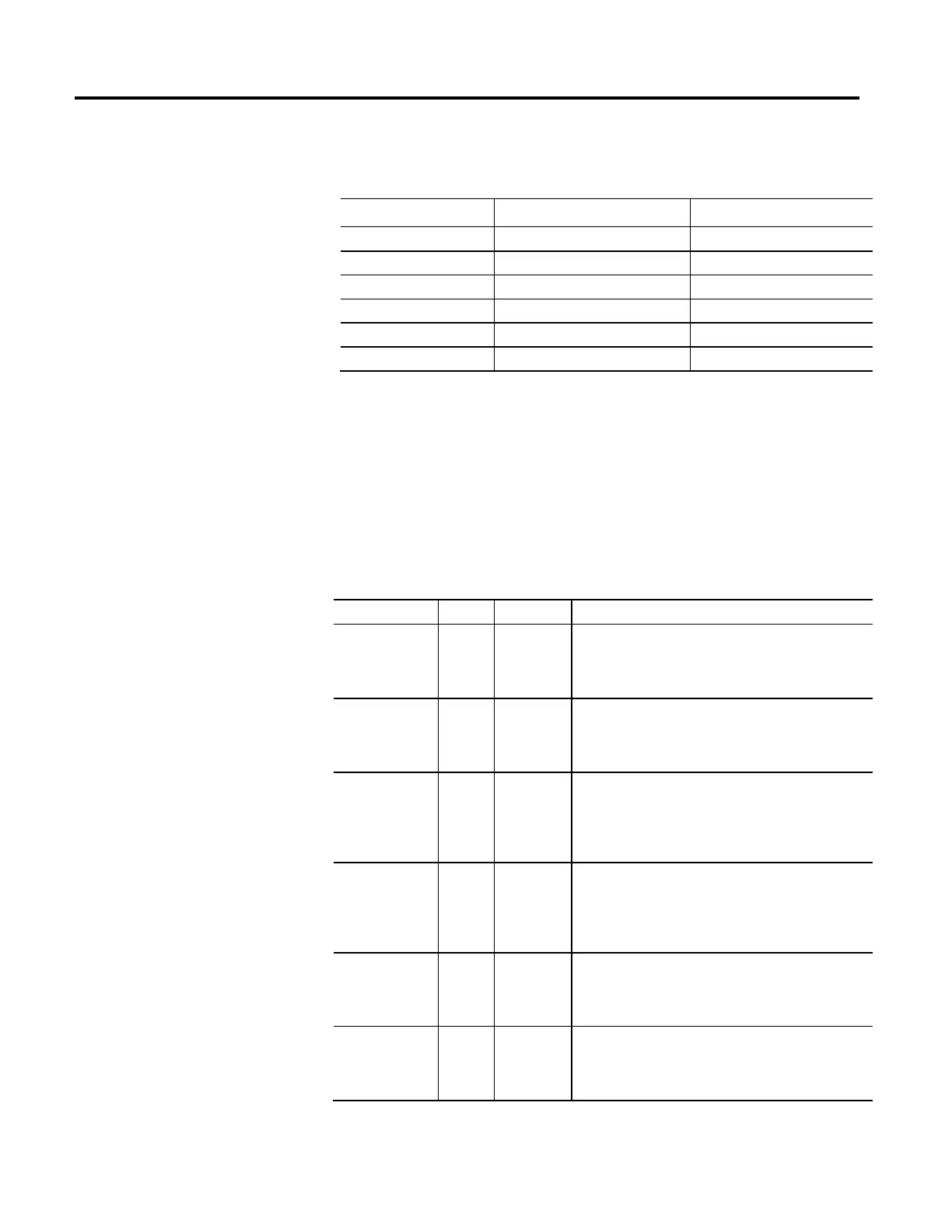

This attribute is used to set both the Control Mode and Control Method

attributes according to the following table:

Axis Config Control Mode Control Method

Converter Only No Control No Control

Feedback Only No Control No Control

Frequency Control Velocity Control Frequency Control

Position Loop Position Control PI Vector Control

Velocity Loop Velocity Control PI Vector Control

Torque Loop Torque Control PI Vector Control

The axis configuration attribute is an enumerated value that determines the

general dynamic control behavior of the motion device axis instance. This

attribute is used by the controller to set the Control Mode attribute that is sent to

the drive as part of the cycle connection, and also determines Control Method

attribute configuration. So, when axis configuration is set by configuration

software, control mode and control method are also updated.

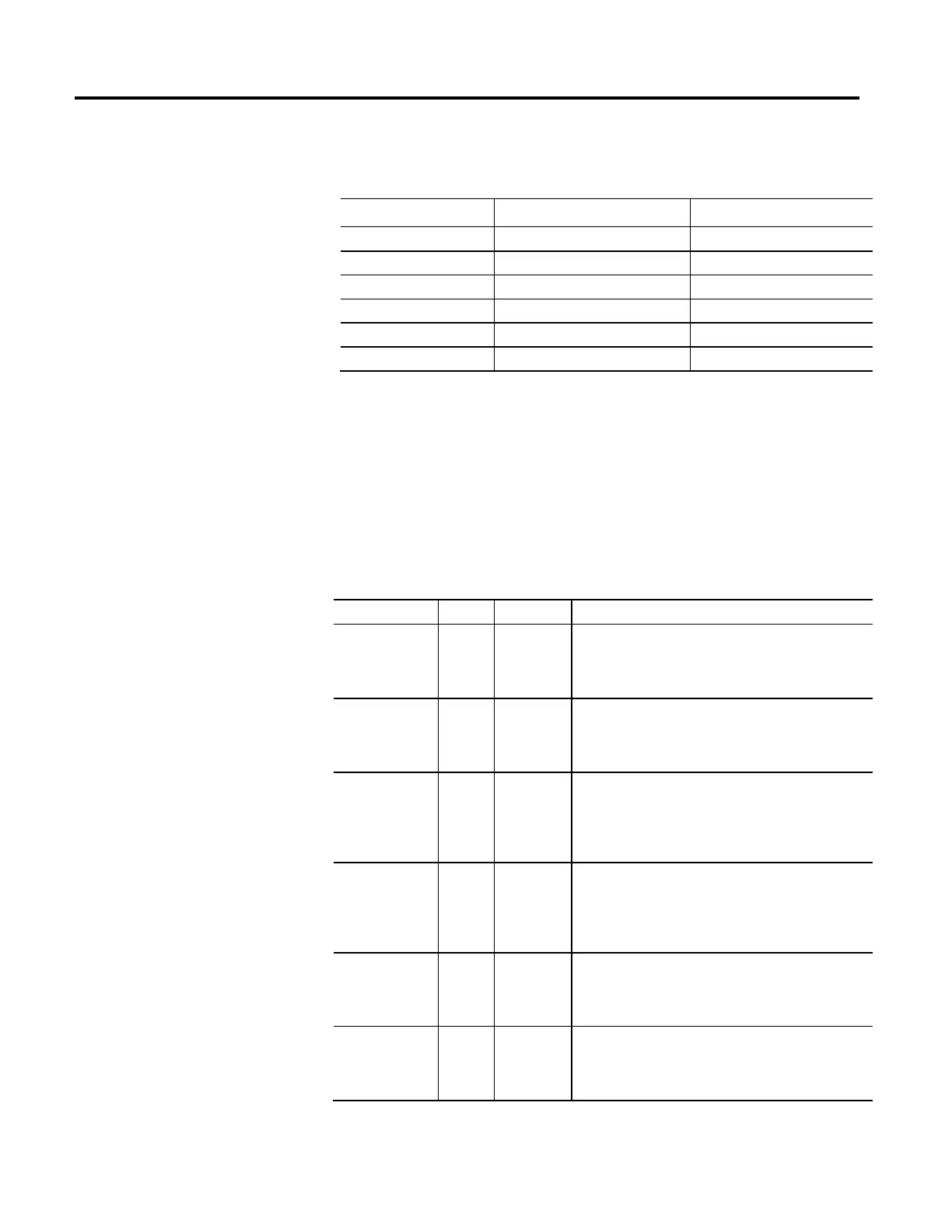

The following table provides descriptions of the Axis configuration attribute

values:

Enumeration Usage Name Description

0 R/N O/C Feedback Only

Provides an axis interface to a specific feedback device as a master

feedback source. The Control Mode and Control Method are set to

No Control in this configuration, indicating that there is no dynamic

control capability associated with this axis.

1 R/F

Frequency

Control

Selects the Frequency Control Method that applies voltage to the

motor, generally in proportion to the commanded frequency or

speed. Accordingly, the Control Mode attribute is set to Velocity

Control.

2 R/P Position Loop

Selects the PI Vector Control Method that applies feedback to

provide closed loop cascaded PI control of motor position, velocity,

and torque, and includes closed loop control of Iq and Id

components of the motor current vector. Accordingly, the Control

Mode attribute is set to Position Control.

3 R/V O/P Velocity Loop

Selects the PI Vector Control Method that applies feedback to

provide closed loop cascaded PI control of motor velocity, and

torque, and includes closed loop control of Iq and Id components of

the motor current vector. Accordingly, the Control Mode attribute is

set to Velocity Control.

4 R/T O/PV Torque Loop

Selects the PI Vector Control Method that applies feedback to

provide closed loop PI control of motor torque through control of Iq

and Id components of the motor current vector. Accordingly, the

Control Mode attribute is set to Torque Control.

5 R/B O/D Converter Only

Provides an axis interface to a standalone power converter device.

Both the Control Mode and Control Method are set to No Control in

this configuration, indicating that there is no dynamic control

capability associated with this axis.

Loading...

Loading...