Rockwell Automation Publication MOTION-RM003I-EN-P - February 2018 339

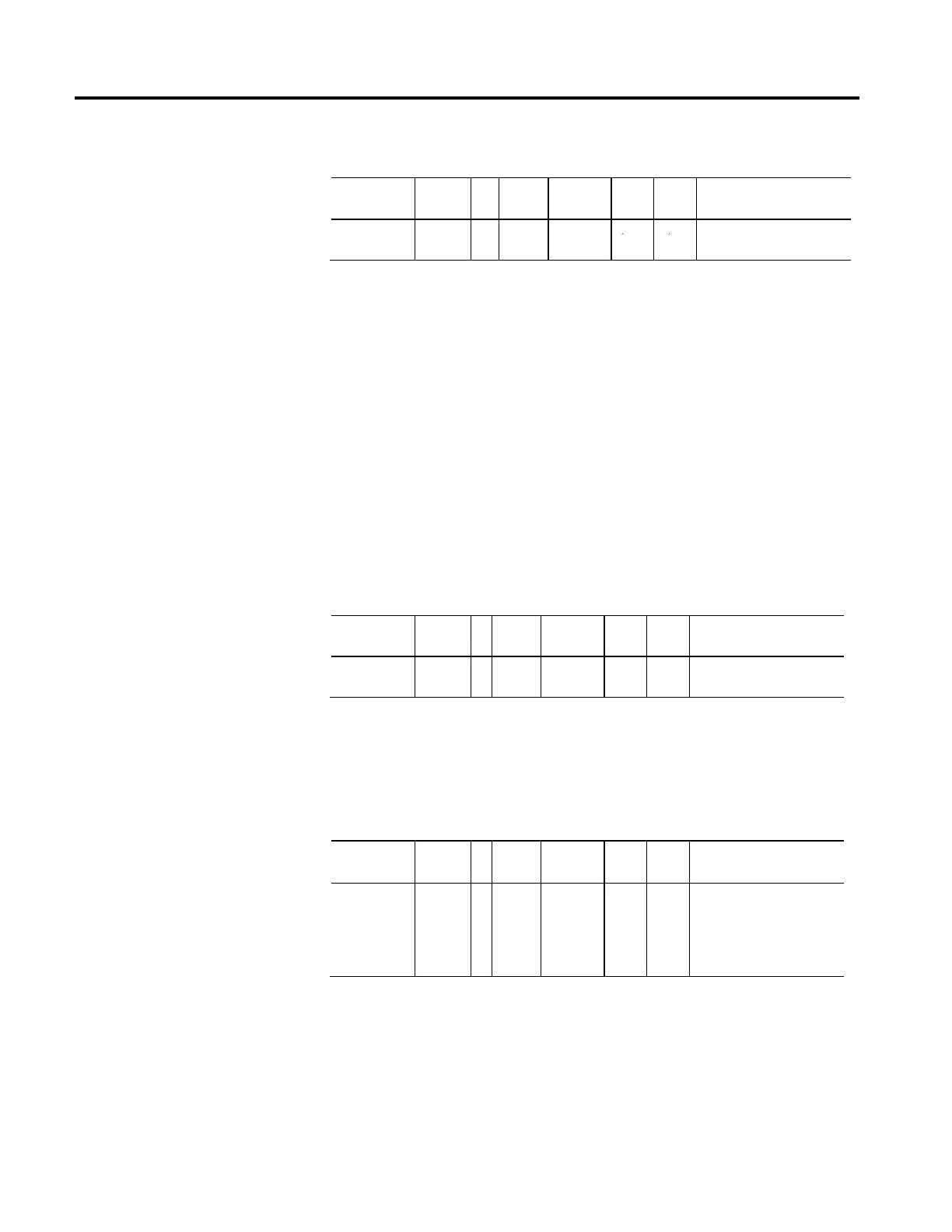

Command Torque

Usage Access T Data

Type

Default Min Max Semantics of Values

Required - VT

Get/

SSV

T REAL 0 - + % Rated

The Command Torque attribute is the commanded torque in units of percent

Rated Torque of the motor. This tag value is transferred by the Logix Processor to

a physical axis as part of an ongoing synchronous data transfer process. Unlike

Command Position, Command Velocity, and Command Acceleration, the

Command Torque attribute is not generated by the motion planner. Instead, the

value may be written directly by the application program.

Command Torque has no effect on the axis unless the axis is configured for

Torque Loop operation. In order for the this attribute's value to be applied as the

torque command, a Motion Drive Start instruction will be executed, which in turn

sets the Direct Torque Control Status bit of the Motion Status Bits attribute. If

this bit is not set, the Command Torque value has no effect on axis motion. Only

CIP Drive Axis data types currently support this capability.

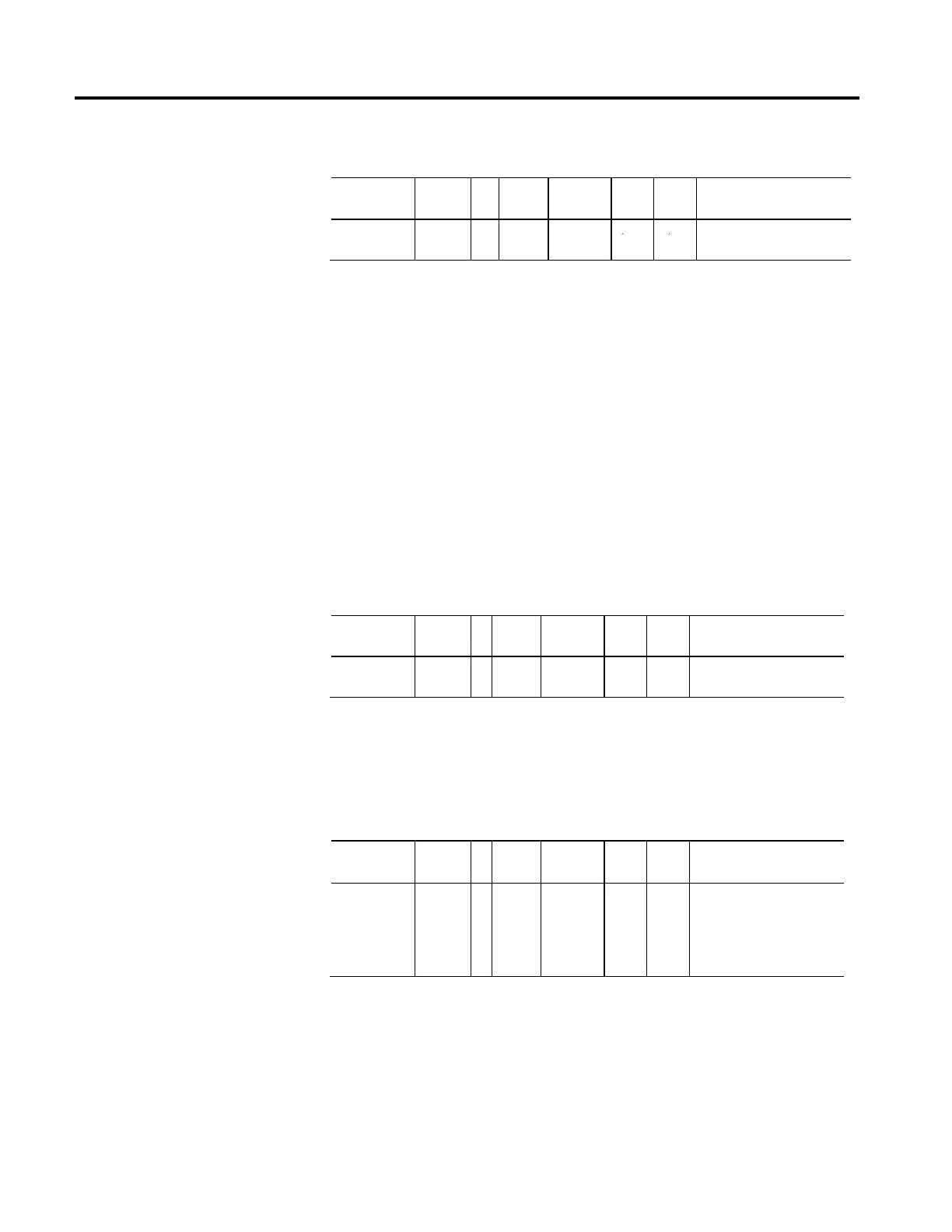

Interpolated Command Position

Usage Access T Data

Type

Default Min Max Semantics of Values

Required - E

PV only

Get/

GSV

T REAL - - - Position Units

The Interpolated Command Position attribute is the interpolation of the

commanded position, based on past axis trajectory history, at the time specified by

the Interpolation Time attribute.

Master Offset

Usage Access T Data

Type

Default Min Max Semantics of Values

Required - FPV

PV only

Get/

GSV*

T REAL - - - Master Position Units

Tag access supported but the

value is valid only when Auto Tag

Update of the Motion Group

Object is enabled.

The Master Offset attribute is the position offset that is currently applied to the

master side of the position cam. The Master Offset is returned in master position

units. The Master Offset shows the same unwind characteristic as the position of a

linear axis. Tag access is supported but the tag value is valid only when Auto Tag

Update of the Motion Group Object is enabled

Loading...

Loading...