380 Rockwell Automation Publication MOTION-RM003I-EN-P - February 2018

• Conversion Constant / Motion Resolution = Motion Units (revs, inches,

or millimeters) / Position Unit

Conversely, all actual position, velocity, and acceleration data from the Motion

Planner is scaled from Motion Units to the user's preferred Position Units based

on the Motion Resolution and Conversion Constant. The ratio of Motion

Resolution and the Conversion Constant determines the number of Position

Units in a Motion Unit as described using the following formula:

• Motion Resolution / Conversion Constant = Position Units / Motion

Unit (rev, inch, or millimeter)

In general, the Motion Resolution value may be may be configured in Motion

Counts per Motion Unit independent of the resolution of the feedback device(s)

used. The drive's scaling function takes care of scaling between Feedback Counts

and Motion Counts. Providing a configurable Motion Resolution value is

particularly useful for addressing Fractional Unwind applications where it is

necessary to have an integer number of Motion Counts per Unwind Cycle.

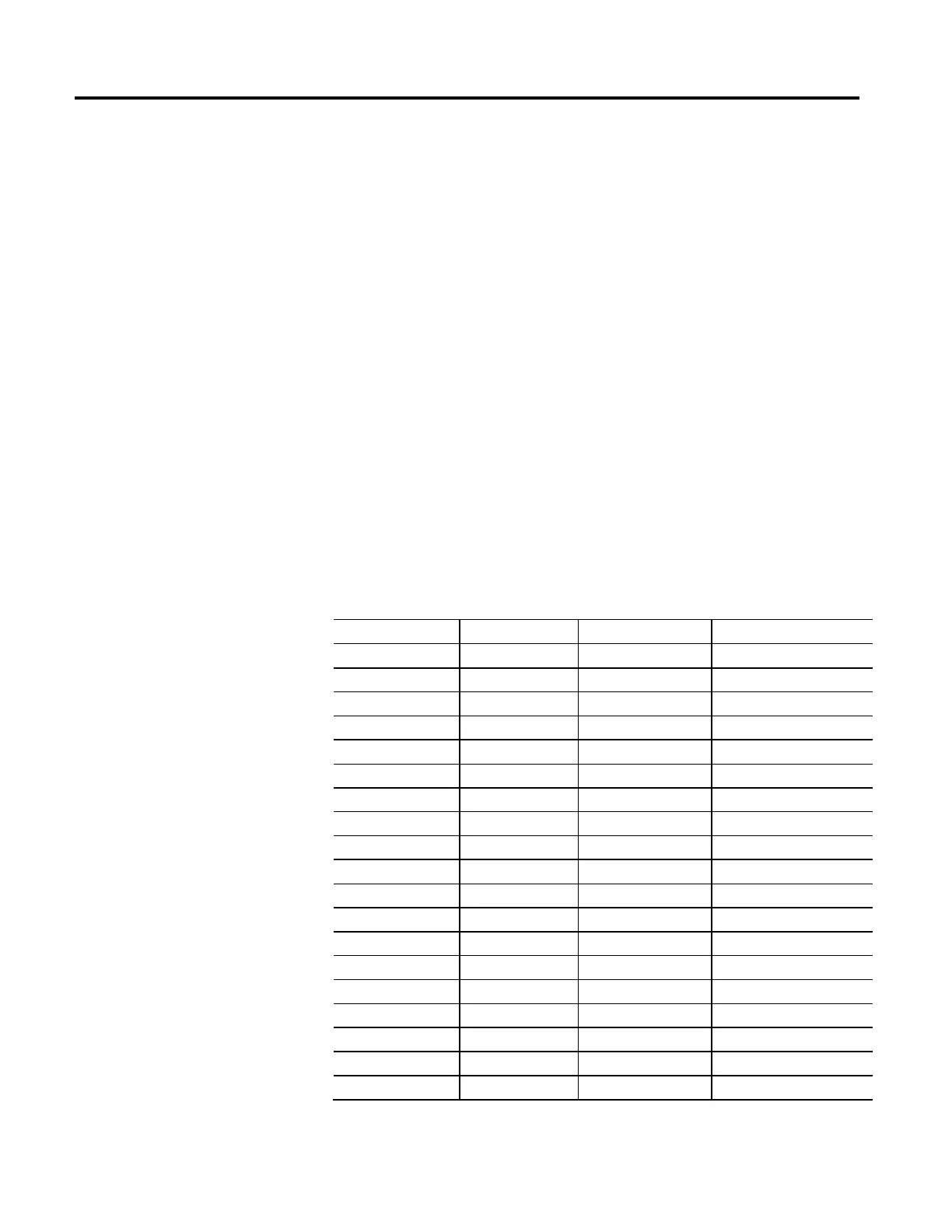

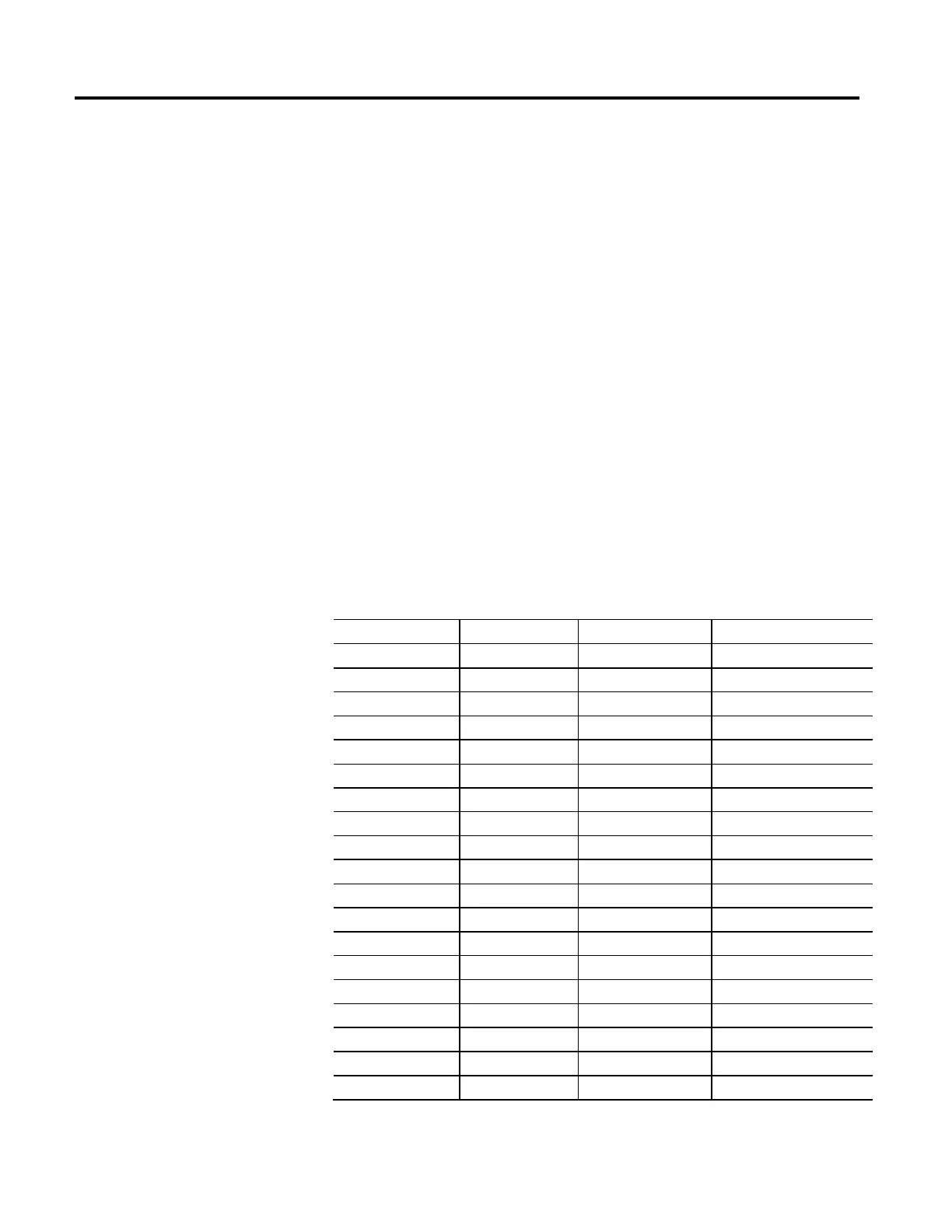

Valid Motion Unit attribute selections are determined by the Feedback

Configuration, Load Type, and Linear Actuator Unit (Lead Unit or Diameter

Unit) values according to the following table:

Feedback Configuration Load Type Linear Actuator Unit Motion Unit

No Feedback Direct Rotary - Motor Rev/s

No Feedback Rotary Transmission - Load Rev/s

No Feedback Linear Actuator mm/rev | mm Load m/s

No Feedback Linear Actuator inch/rev| inch Load inch/s

Master Feedback Direct Rotary - Feedback Rev

Master Feedback Direct Linear - Feedback mm

Master Feedback Rotary Transmission - Load Rev

Master Feedback Linear Actuator mm/rev | mm Load mm

Master Feedback Linear Actuator inch/rev| inch Load inch

Motor Feedback Direct Rotary - Motor Rev

Motor Feedback Direct Linear - Motor mm

Motor Feedback Rotary Transmission - Load Rev

Motor Feedback Linear Actuator mm/rev |mm Load mm

Motor Feedback Linear Actuator inch/rev | inch Load inch

Load | Dual Feedback Direct Rotary - Load Rev

Load | Dual Feedback Direct Linear - Load mm

Load | Dual Feedback Rotary Transmission - Load Rev

Load | Dual Feedback Linear Actuator mm/rev | mm Load mm

Load | Dual Feedback Linear Actuator inch/rev | inch Load inch

Loading...

Loading...