442 Rockwell Automation Publication MOTION-RM003I-EN-P - February 2018

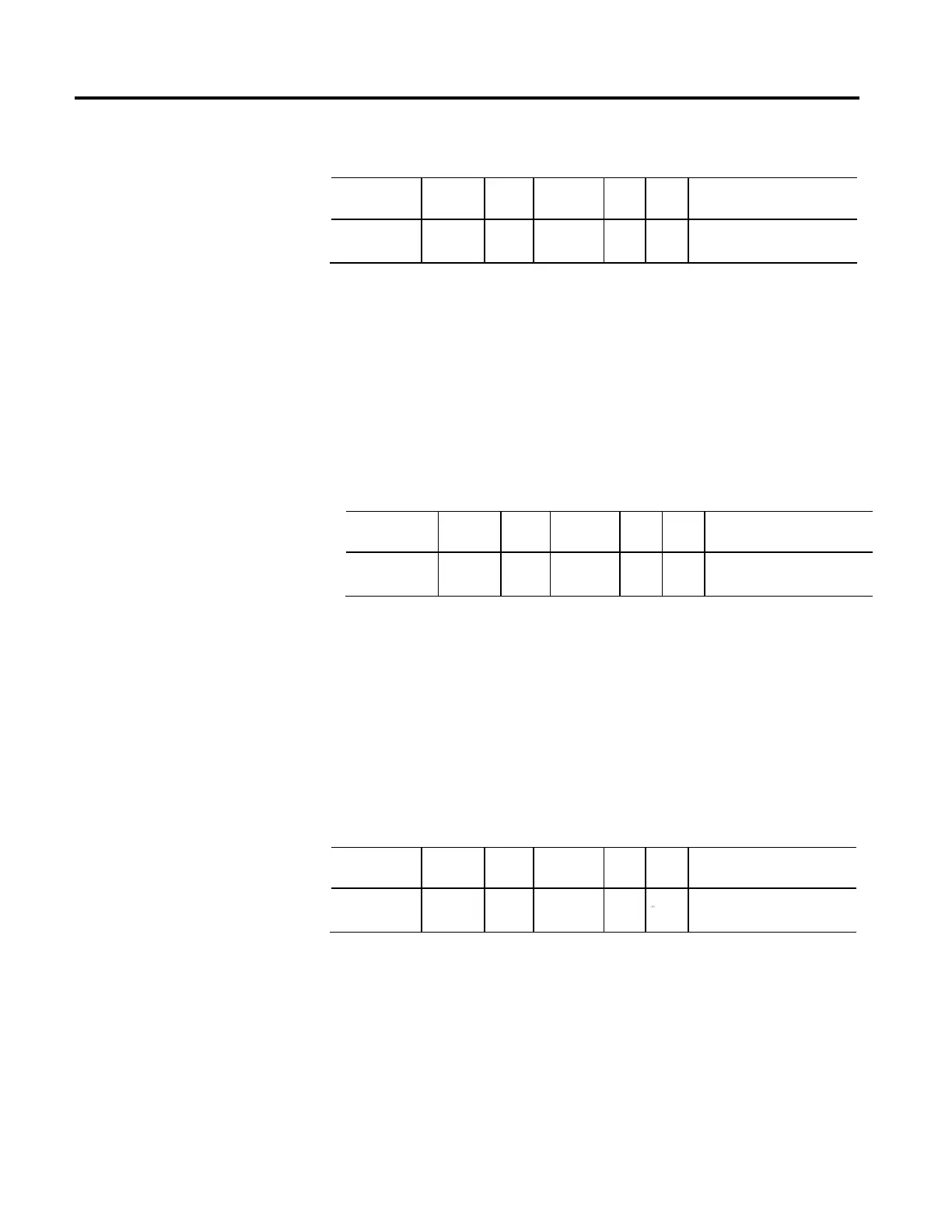

Brake Test Torque

Usage Access Data

Type

Default Min Max Semantics of Values

Optional - DE Set/SSV REAL 0

FD

0 10

3

% Motor Rated

This attribute sets the percent of motor rated torque applied to the motor by the

Brake Test as part of the Torque Proving function executed in the Starting state.

This Brake Test proactively tests the ability of the mechanical brake to hold the

maximum anticipated load before releasing the brake and allowing operation.

Should the Brake Test detect brake slip, a Brake Slip exception is generated.

If the Brake Test Torque attribute value is 0 the Brake Test is not performed in

the Starting state.

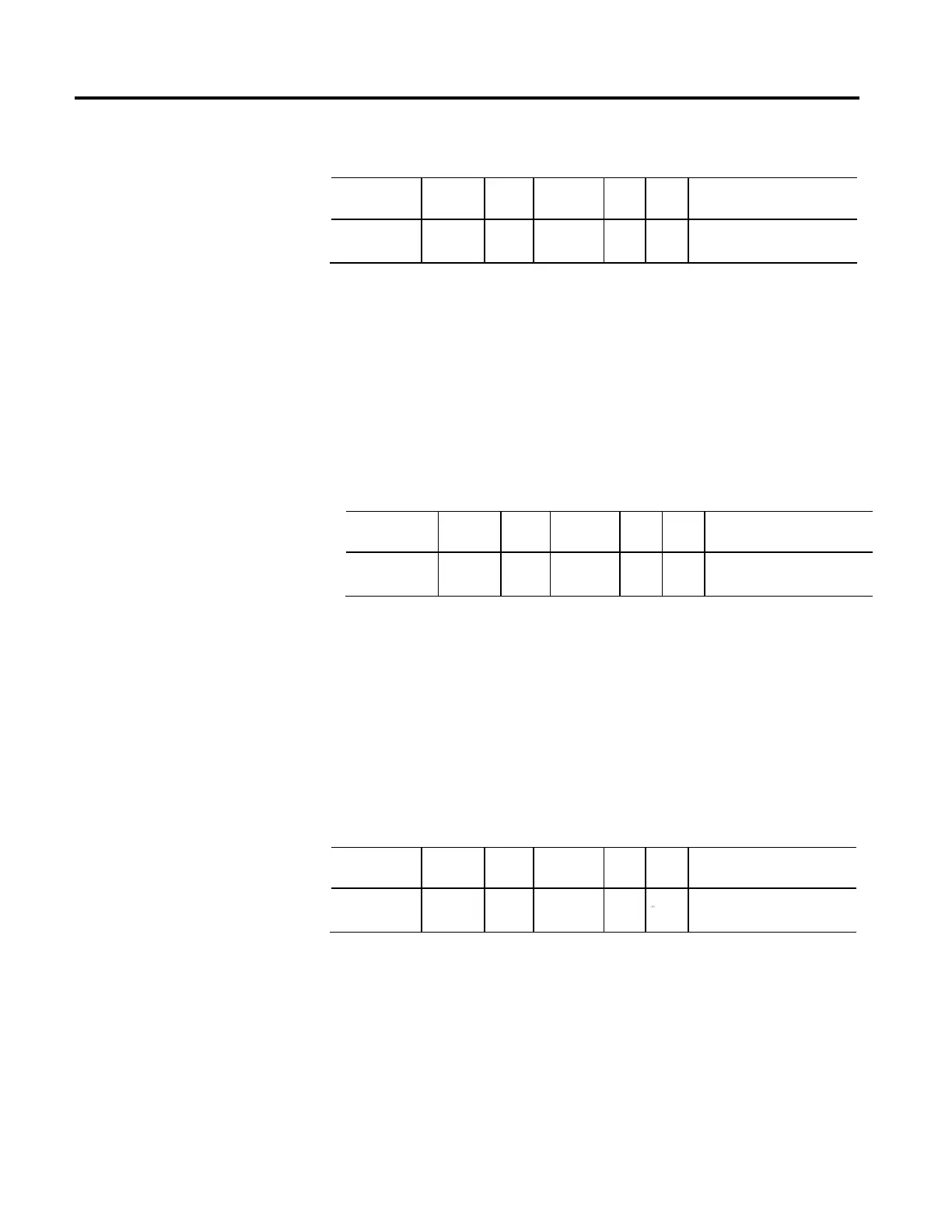

Brake Prove Ramp Time

Usage Access Data

Type

Default Min Max Semantics of Values

Optional - DE Set/SSV REAL 0

FD

0 10

3

Seconds

This attribute determines the amount of time the drive will take to ramp the

applied torque of the motor down to zero during the Brake Proving test in the

Stopping or Aborting state. The Brake Prove Ramp Time determines the ramp

down rate of the applied torque output by dividing the Torque Limit by the Brake

Prove Ramp Time. The Torque Limit in this case is the maximum of the

configured Torque Limit Positive and Torque Limit Negative values. The Brake

Prove test is performed to check for brake slip before the power structure is

disabled.

Brake Slip Tolerance

Usage Access Data

Type

Default Min Max Semantics of Values

Optional - DE Set/SSV REAL 0

FD

0

Position Units

This attribute determines the amount of brake slip allowed after the brake is

engaged. If this tolerance is exceeded while the brake is engaged, a Brake Slip

exception is generated. Brake slip can therefore be monitored in any axis state

where the brake is engaged.

Loading...

Loading...