466 Rockwell Automation Publication MOTION-RM003I-EN-P - February 2018

• 0 = Ignore (All)

• 1 = Alarm (All)

• 2 = Fault Status Only (B, D)

• 3 = Stop Planner (D)

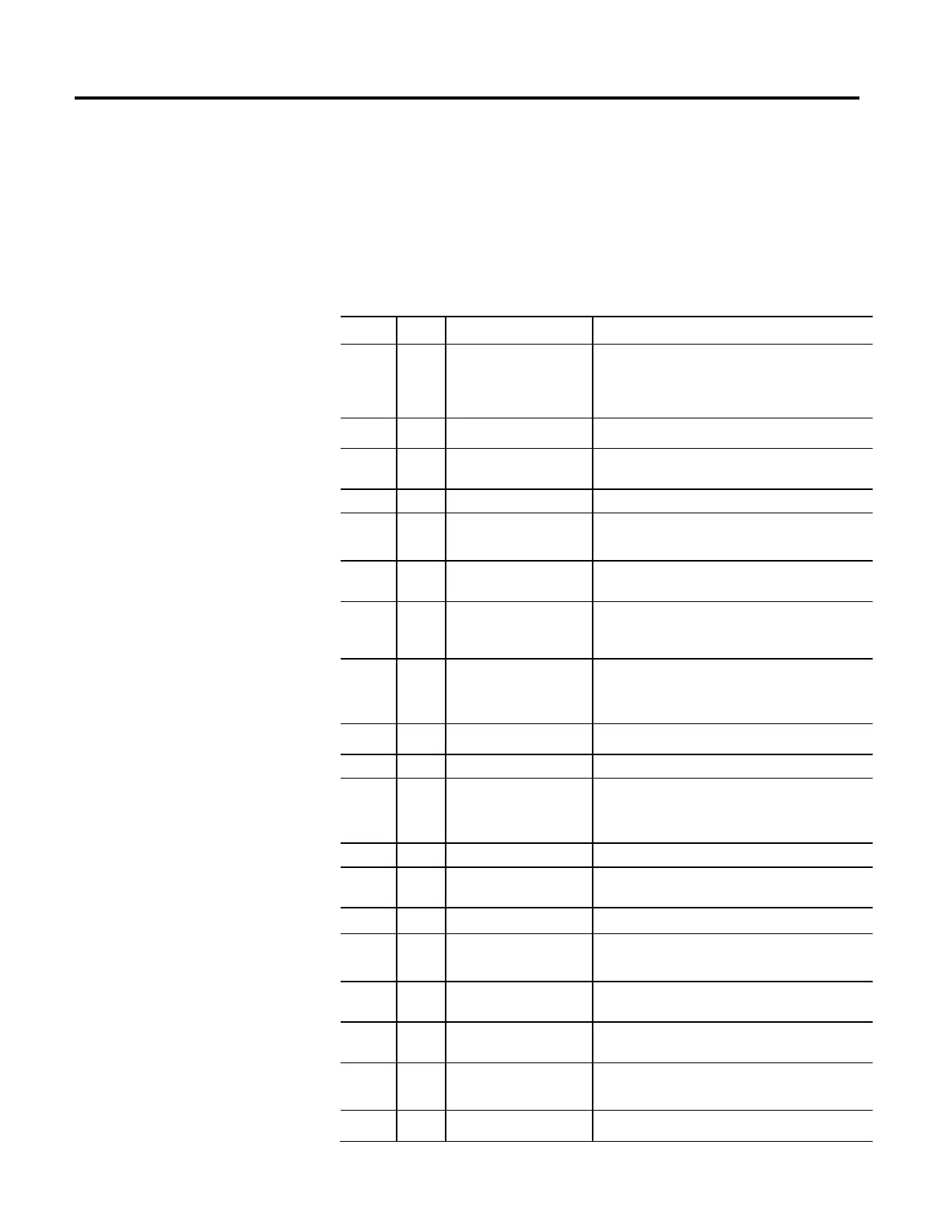

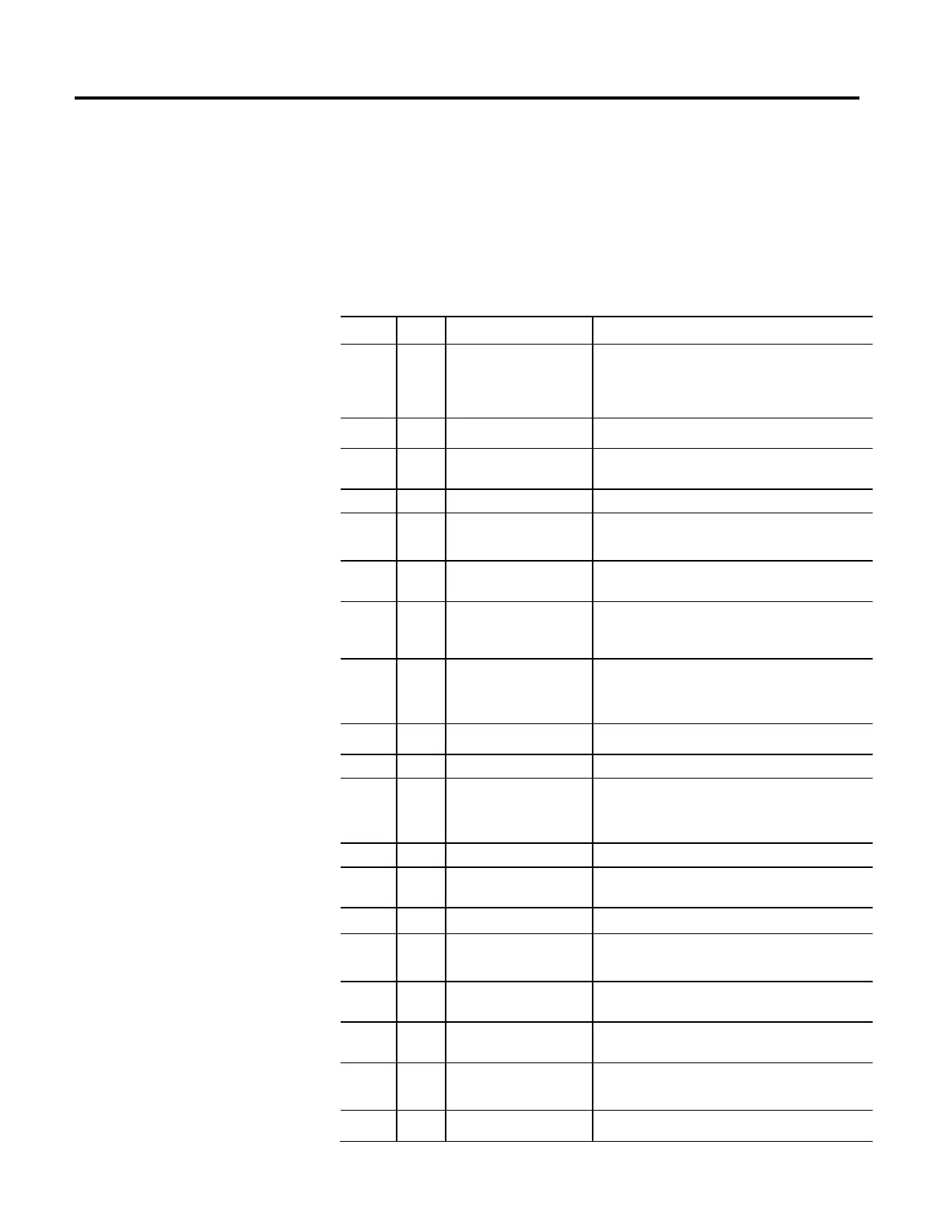

Rockwell Automation Specific Exception Table

Bit Rule Exception Name Description

0 - -- Reserved --

This bit cannot be used since the Alarm Codes and Fault Code

are defined by the associated exception bit number and an

Alarm Code or Fault Code of 0 means no alarm or fault

condition is present.

1 D Commutation Startup Failure The self-sensing commutation startup algorithm failed.

2 D Motor Voltage Mismatch

The motor voltage is incompatible with the applied drive

voltage.

3 - -- Reserved --

4 E Feedback Filter Noise

Excessive levels of noise have been detected by the digital

feedback filter.

5 E Feedback Battery Loss

The battery charge level is too low and encoder power has

been removed possibly resulting in loss of absolute position.

6 E Feedback Battery Low

The battery charge level is too low but encoder power has not

yet been removed. This is intended as a warning that if

encoder power is lost absolute feedback position could be lost.

7 E

Feedback Incremental Count

Error

The periodic check of the incremental encoder position against

the absolute encoder position or Hall edges indicates they are

out of tolerance.

8 - -- Reserved --

9 - -- Reserved --

10 ALL

Control Module

Overtemperature FL

Kinetix: The control module temperature has exceeded its

limit. Rhino: The temperature sensor on the Main Control

Board detected excessive heat.

11

--Reserved--

12 BD

Converter Pre-Charge Overload

FL

Converter estimates that the pre-charge circuit has exceeded

its factory limit due to excessive power cycling.

13

--Reserved--

14 BD

Excessive Current Feedback

Offset

Current in one or more phases has been lost or remains below

a preset level.

15 BD

Regenerative Power Supply

Failure

The hardware Regeneration OK input was deactivated while

the drive was enabled.

16 D PWM Frequency Reduced

Carrier Frequency foldback due to excessive Junction

Temperature.

17 D Current Limit Reduced

Current Limit reduced due to excessive Junction Temperature

or due to Overload Protection.

18 D Torque Prove Failure Actual feedback indicates error in torque proving.

Loading...

Loading...