Medium-consistency pump MC

STANDARD, C-01-000000

Rev. 0, 2010.02.09 MAINTENANCE Kap.7 , Seite 5 of 22

GRZ-2698573-v1-Maintenance.FM

7.5 Fasteners

Screw/bolt

material

Bolts and screws are manufactured in several classes of material. The

heads of these screws and bolts are marked to show the strength class.

Damaged or lost fasteners should only be replaced with fasteners of the

same material.

Check Unless they are suitably tightened, screws/bolts can work loose or fail

under operating conditions. This is why all connecting screws/bolts must

be checked in the course of maintenance work.

• During the first six months: every 2 to 2½ months

• After the first six months: 6-monthly

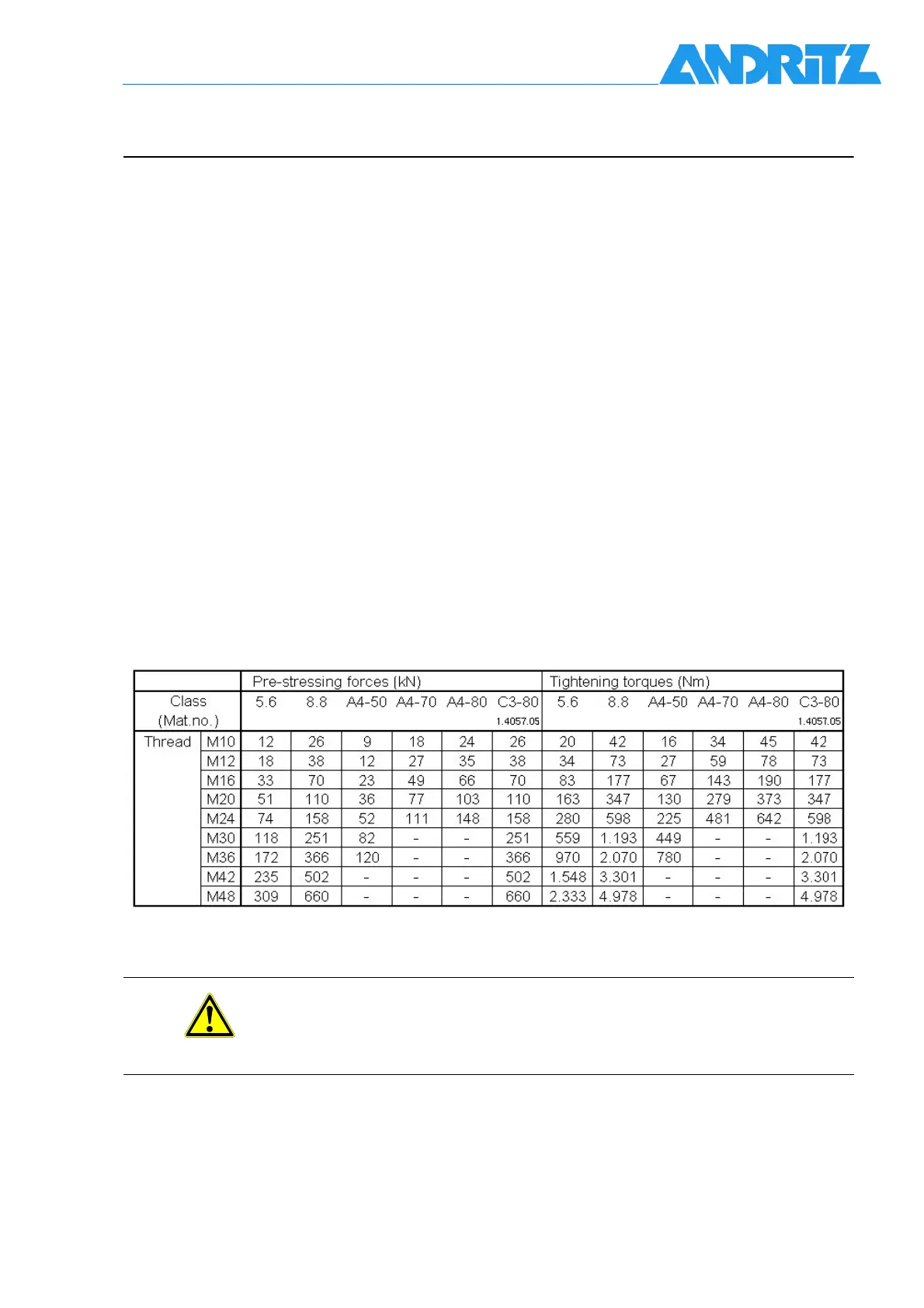

Tighten During checks and maintenance work it is imperative to tighten all

connecting screws/bolts to the torque specified for each one in the

drawings or in the table below.

Pre-stressing forces and tightening torques in the table apply to normal

screwed/bolted connections. Please contact Andritz AG if you have

special requirements.

The thread and screw head should be lubricated with an appropriate

lubricant (for example Molyslide Plus from Loctite).

Tab. 7-5 Tightening Torques and Pre-stressing Forces for Rigid Screws(Normal thread)

CAUTION

Wrong torque tightening may cause machine damage and hazards

leading to personal injury.

The pre-loads and tightening torques above

must be observed.

Loading...

Loading...