Medium-consistency pump MC

STANDARD, C-01-000000

Rev. 0, 2010.02.09 MAINTENANCE Kap.7 , Seite 14 of 22

GRZ-2698573-v1-Maintenance.FM

7.8.2 Removing and installing the impeller,

fluidisator, casing cover and mechanical seal

Removing the

impeller

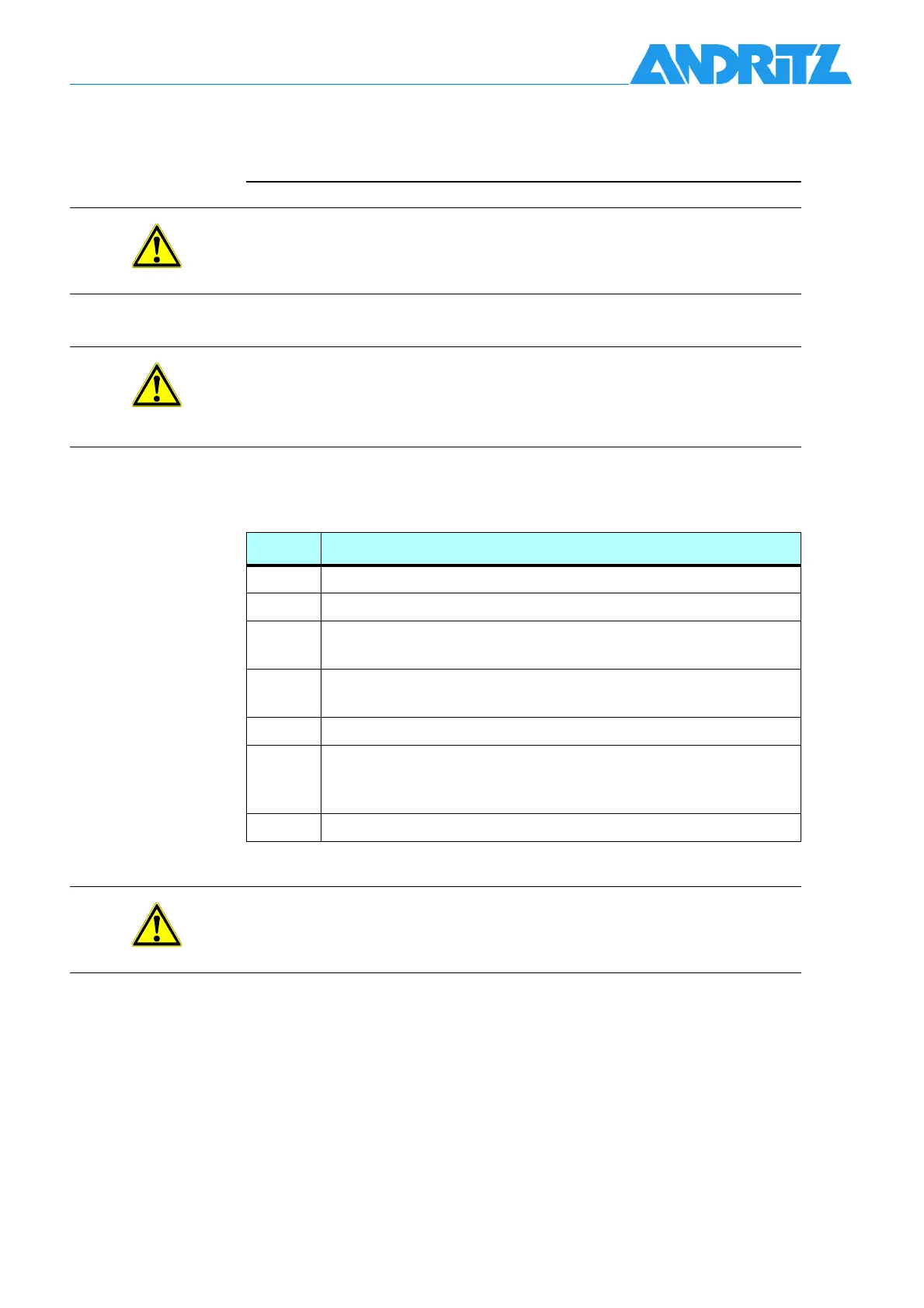

Proceed according to the following table when removing the impeller:

DANGER

Limbs can be trapped or crushed during disassembly work.

DANGER

of injury at the impeller and fluidisator!

Impellers may have very sharp edges, particularly when they are

worn.

Wear protective clothing and gloves!

Step Activity

1 Remove pump unit according to section 7.8.1.

2 Detach locking plate (931.2).

3 Remove hexagon head screw (901.2), locking plate (931.1)

and washer (

260)

4 Pull off fluidisator (230.2) and impeller (230.1) by pushing it off

the casing cover (

161)

5 Pull out casing cover (161) (incl. mechanical seal (433))

6 Dismantle and detach mechanical seal (433) by removing

hexagon nuts (

920.9), waschers (544.5) and locking screws

(

902.5).

7 Re-assemble in reversed order

Tab. 7-13 Removing the impeller

WARNING

When assembling the fluidisator, be aware that the fixing screw has

to be mounted with the provided torque of 279 Nm.

Loading...

Loading...