LUBRICATION

59 AU103170 H5B

1. Clean the area around the breather with cleaning

solvent.

2. Remove the breather.

3. Clean the breather with cleaning solvent.

4. Dry the breather with compressed air. Always wear

face protection when using compressed air.

5. Install the breather.

Suction Screens

Clean the suction screens every 1,000 hours of operation

or once each year, whichever occurs first.

There are two (2) suction screens installed inside the

hydraulic reservoir. The suction screens are located at the

back of the reservoir near the bottom.

NOTE:

It is recommended that you clean the hydraulic

suction screens when you change the hydraulic fluid. See

Fluid Change in this manual.

1. See Fluid Change in this manual and do steps 1

through 5.

2. Remove the clamps and hoses.

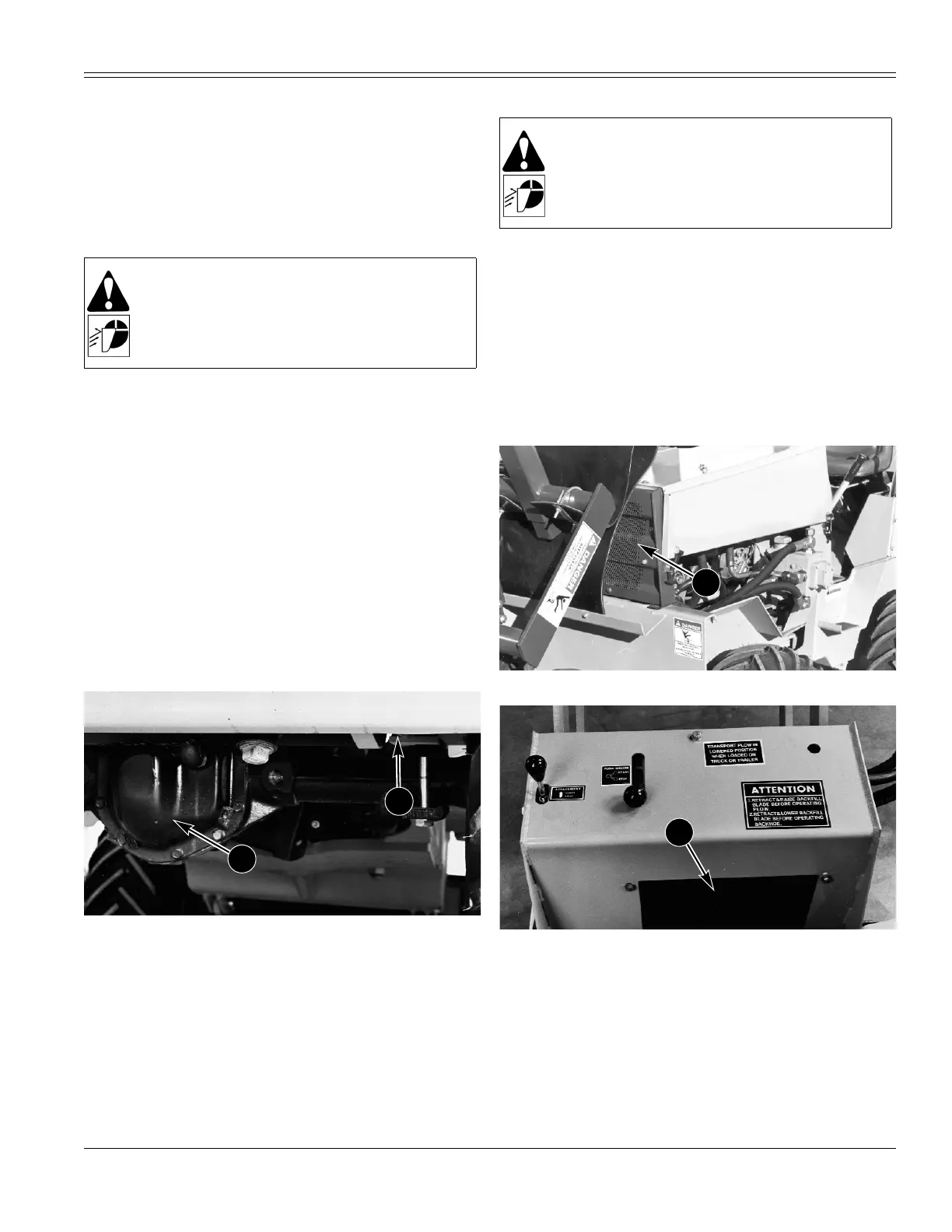

866365

1. FRONT AXLE DIFFERENTIAL (REFERENCE)

2. SUCTION SCREENS (NOT SHOWN)

3. Remove the suction screens (2).

4. Clean the suction screens in cleaning solvent.

5. Dry the suction screens with compressed air. Always

wear face protection when using compressed

air.

6. Flush the reservoir with cleaning solvent.

7. Install the suction screens.

8. Install the hoses and clamps.

9. See Fluid Change in this manual and do steps 7

through 12.

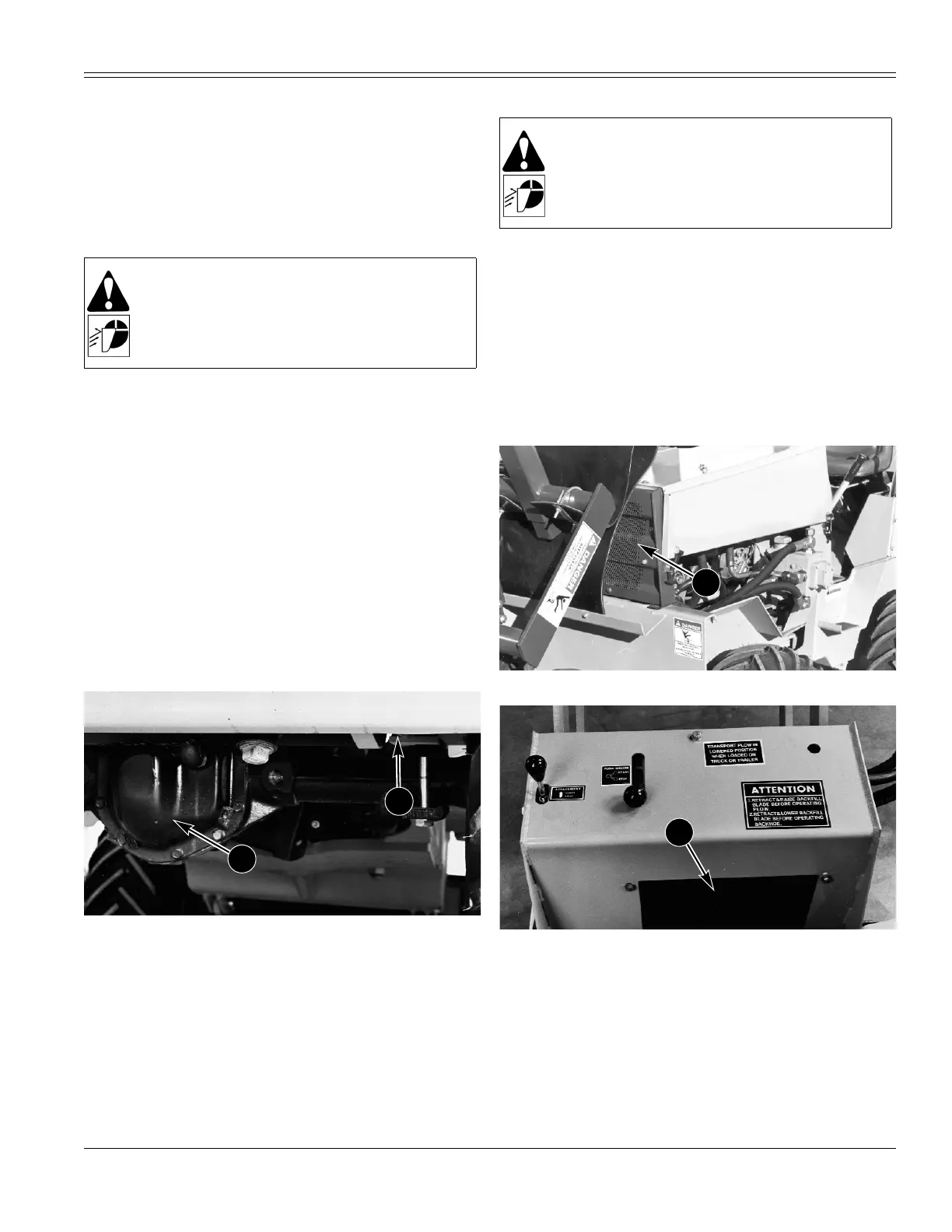

Hydraulic and Plow Coolers

Clean the hydraulic cooler fins (1) and the plow cooler fins

(2) every 250 hours of operation.

PIC00117

1. HYDRAULIC SYSTEM COOLER

A18939

2. PLOW COOLER FINS

WASHING: Washing is the best method for cleaning the

cooler fins. Use a high pressure washer with a mild

detergent to remove the dirt and debris from the cooler

fins. Always wear face protection when using high

pressure washer.

WARNING:

Always wear face protection when

using compressed air.

1

2

WARNING:

Always wear face protection when

using compressed air.

1

2

Loading...

Loading...