Manual, Robotic Tool Changer, QC-5 through QC-27

Document #9610-20-2254-09

Pinnacle Park • 1041 Goodworth Drive • Apex, NC 27539 USA • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com

28

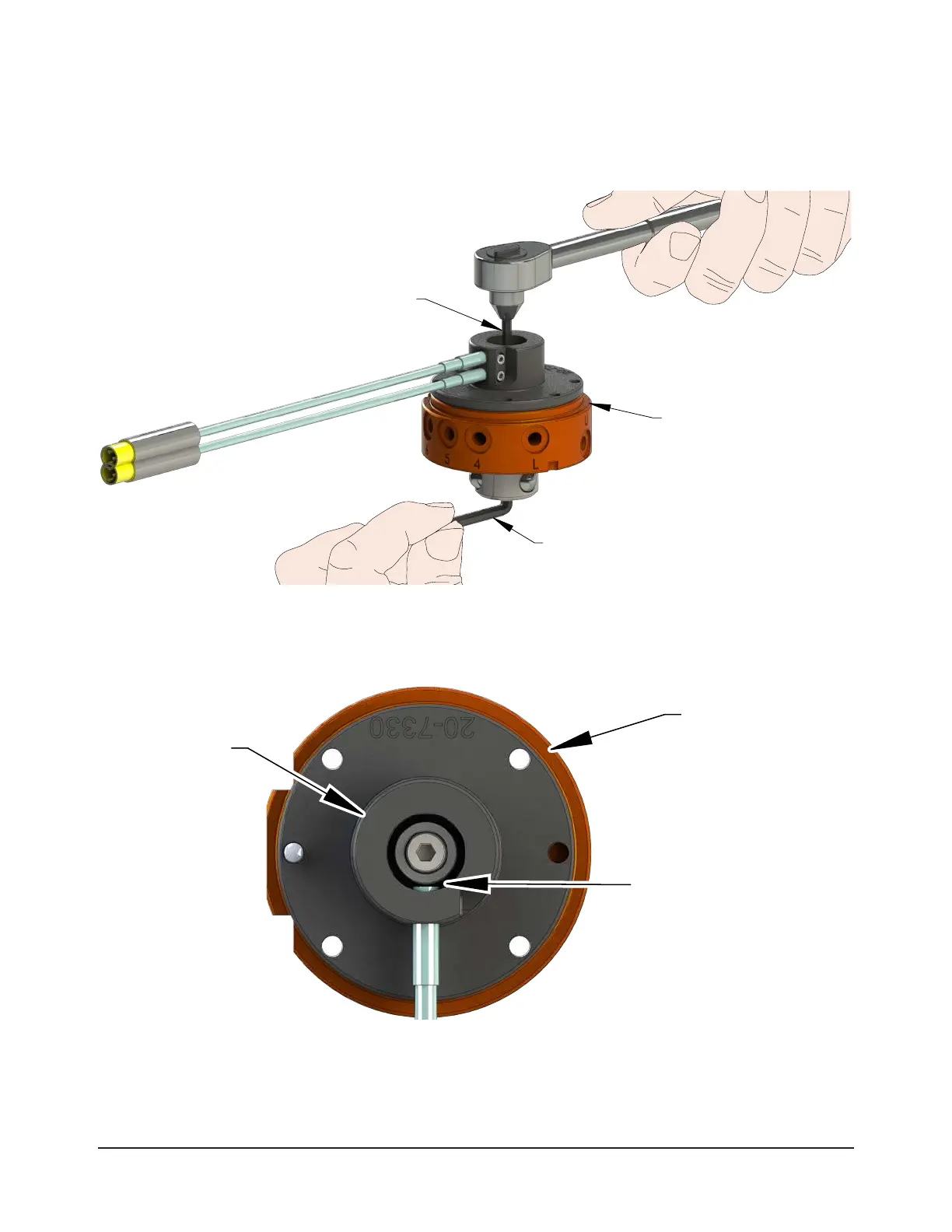

10. Insert a 3 mm hex key into the cam of the Tool Changer plate locking mechanism to

hold the piston.

11. Using a 2.5 mm hex key, tighten the M3 socket head cap screw to 12 in-lbs (1.36 Nm).

Figure 3.12—QC-11 Sensor Plate Assembly Installation

Tool Changer

Master Plate

3 mm Hex Key

2.5 mm Hex Key

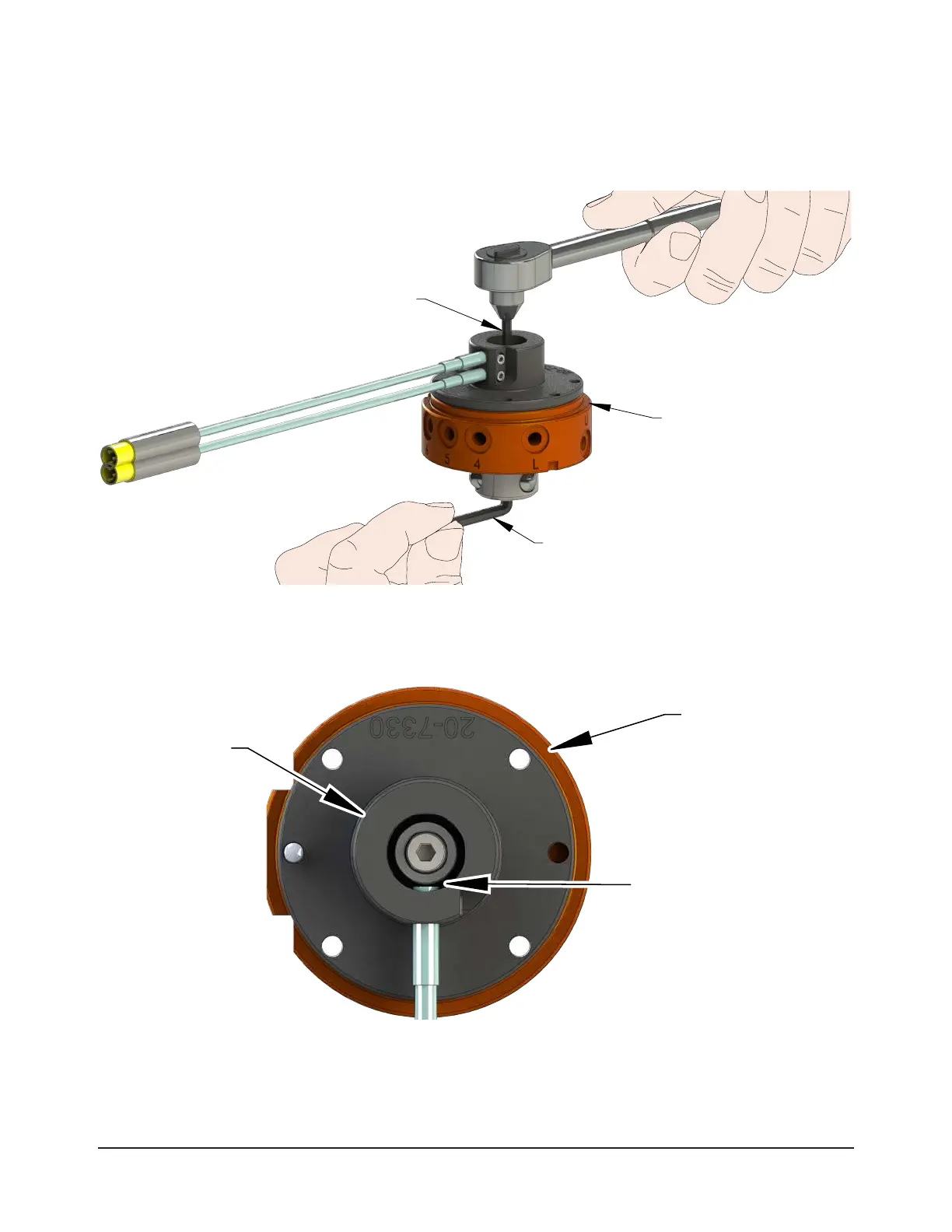

12. Look straight into the sensor plate assembly and verify the detection shaft does not touch the

Lock and Unlock sensors. If the sensors touch the shaft, adjust the sensor position. Refer to

Section 6.2.1—QC-11 and QC-27 Proximity Sensor Adjustment, Test, or Replacement.

Figure 3.13—Verify Sensor and Detection Shaft Clearance

Tool Changer

Master Plate

Clearance Between the

Lock/Unlock Sensors

and Detection Shaft

Sensor Plate

Assembly

Loading...

Loading...