Manual, Robotic Tool Changer, QC-5 through QC-27

Document #9610-20-2254-09

Pinnacle Park • 1041 Goodworth Drive • Apex, NC 27539 USA • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com

5

Glossary

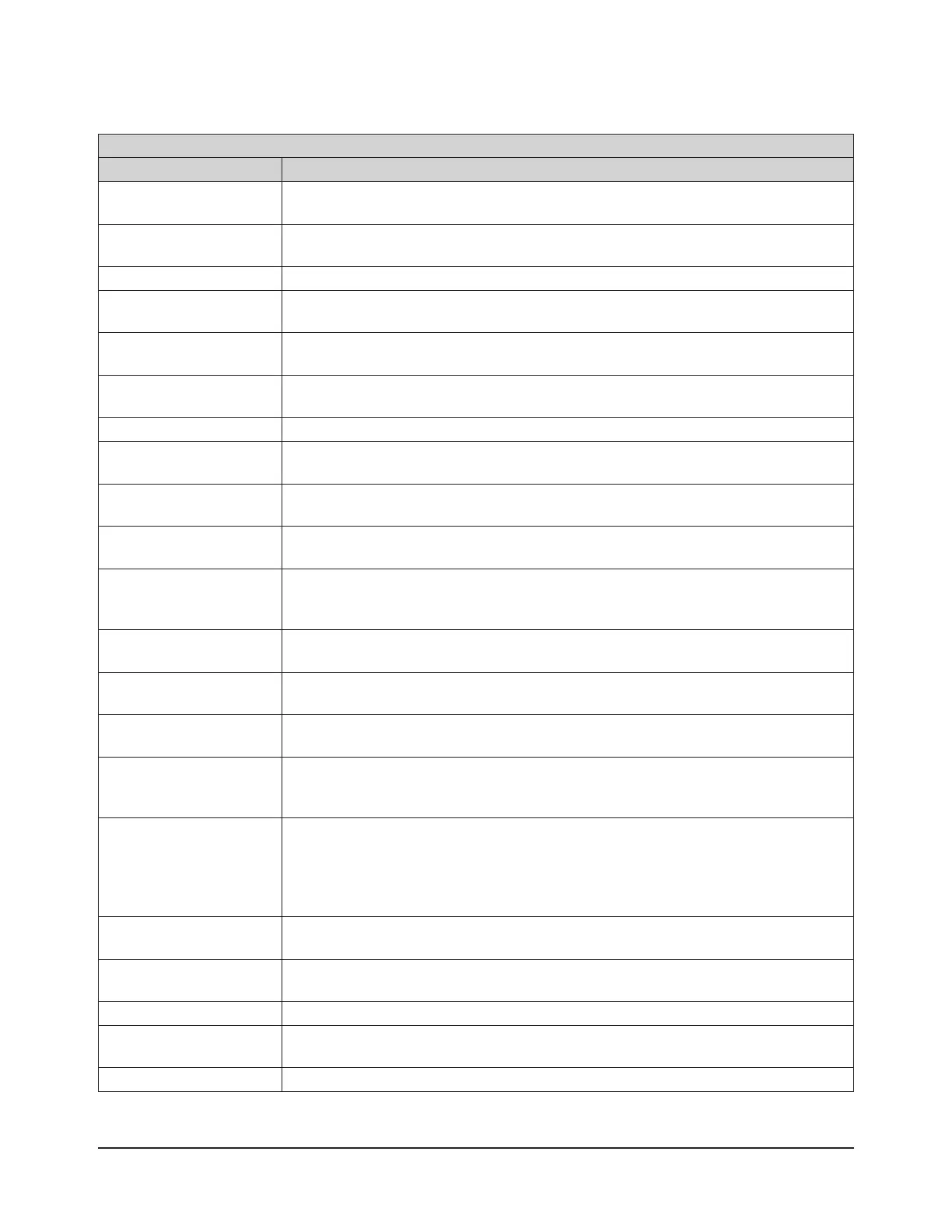

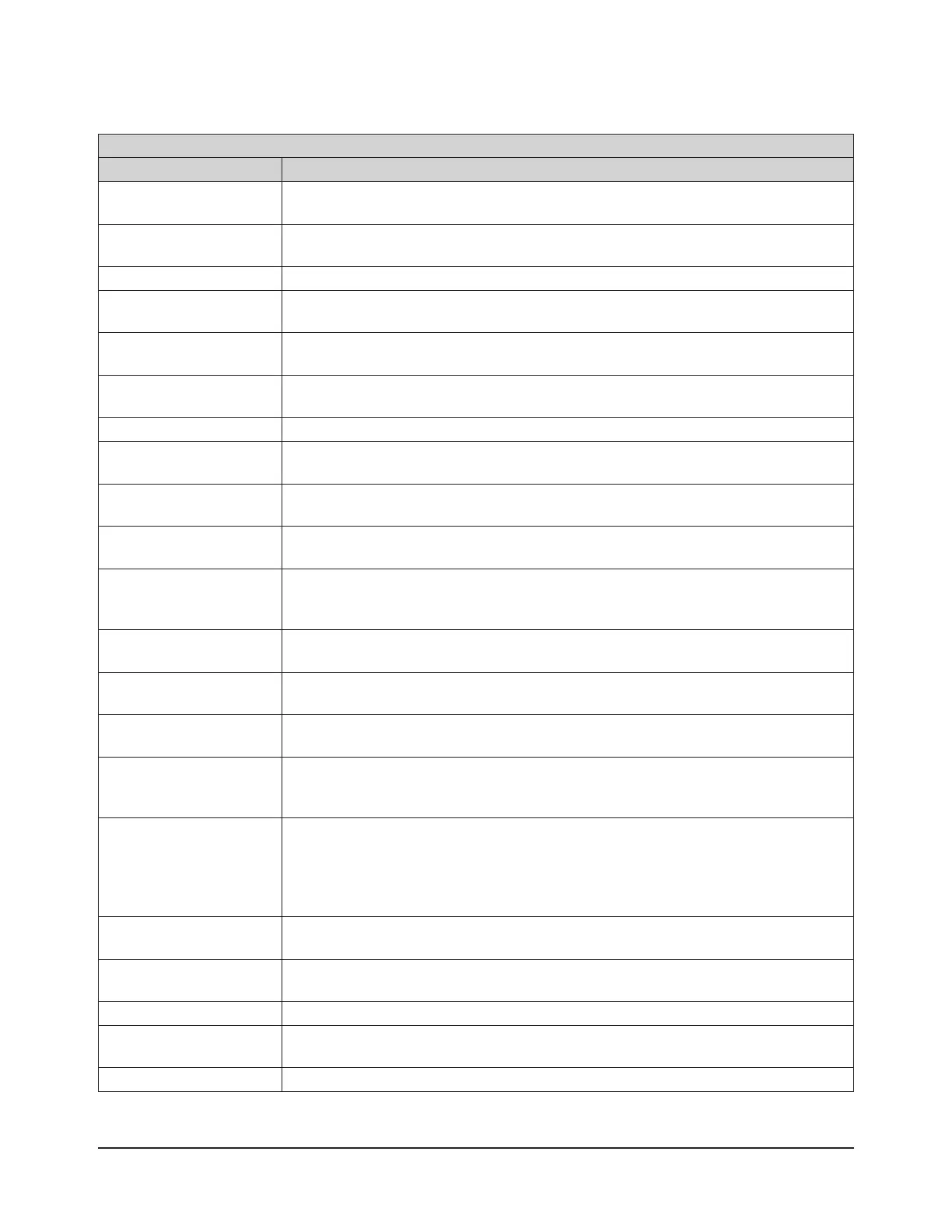

Table 1.1—Tool Changer and Module Glossary

Term Denition

Bearing Race

A steel ring in the Tool plate that is engaged by the locking balls during the

coupling of the Tool Changer.

Cam

A multi tapered sliding cylinder attached to the piston that forces the locking balls

outward during the locking process.

Coupling The physical action of the locking the Master and Tool plates together. See Lock.

Cover Plate

A protective closure plate on the standard Master assemblies which closes the

pneumatic chamber.

Detection Shaft

A threaded stem inserted into the robot side of the piston and functions as a

target to actuate the Lock/Unlock sensors.

Electrical Module

Utility modules that pass electrical power and signals through the Master and

Tool modules to the end-effector.

End-Effector Tool used by the robot to perform a particular operation or function.

Fluid Module

Utility modules that pass uids through the Master and Tool modules to the end-

effector.

High Current Module

Utility modules that pass electrical power through the Master and Tool modules to

the end-effector.

Interface Plate (IP)

An optional customized component that is used to adapt a Tool Changer to the

user’s robot or tooling.

Lock

The lock air pressure that is provided to the Master plate locking mechanism to

force the cam to press the locking balls against the bearing race and lock the

Master and Tool plates together.

Lock Port

A pneumatic port on the Master plate through which air pressure is supplied to

Lock the Master plate to the Tool plate.

Lock Sensor

A proximity sensor that detects the position of the pneumatically actuated piston

when it is in the locked or missed tool position.

Locked

An output signal provided by a proximity sensor that indicates the coupling

mechanism is in the Locked position.

Locking Balls

Hardened steel ball bearings used in the fail-safe locking mechanism. The

locking balls are forced outward by the cam against the bearing race to pull the

Master and Tool plates together.

Locking Mechanism

A manual, pneumatic or electrical driven device that draws the Master and

Tool plates together and secures them in a fail-safe locked condition until the

mechanism is unlocked. The locking mechanism consists of locking balls, cam,

ball cage, bearing race, and either an lever, pneumatic cylinder, or an electric

motor.

L/U

Lock/Unlock sensing capability that allows the customer to determine the state of

the Master assembly locking mechanism.

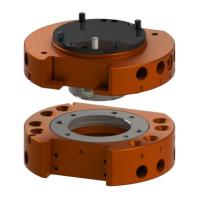

Master plate

The half of the Tool Changer that is mounted to a robot. The Master plate

contains the locking mechanism.

Moment The applied force multiplied by the distance it is from a point.

No-Touch™

A design feature of all ATI Tool Changer products that allows the Master plate

and Tool plate to couple without physical contact prior to locking.

Piston A cylinder located in the Master plate that actuates the locking mechanism.

Loading...

Loading...