Condition Fault Remedy

No enough air flow

during the test.

Disconnect the strainer (4-View of OSCi inlet) and take out

the strainer. Clean the strainer and the nozzle with

compressed air and dry tissue. Check that the air tube does

not touch any other components and is not hindered in any

way. Repeat the test procedure.

If the airflow coming out of the air tube is still not sufficient,

order a spare part solenoid valve (3-OSCi air injection).

In case there was enough airflow during the test, check to

see if there is a thick oily condensate present in all 3

vessels. Then check the oil separator element and the

scavenge line flow of the compressor and order the

corresponding service kits in case these components are

not working correctly.

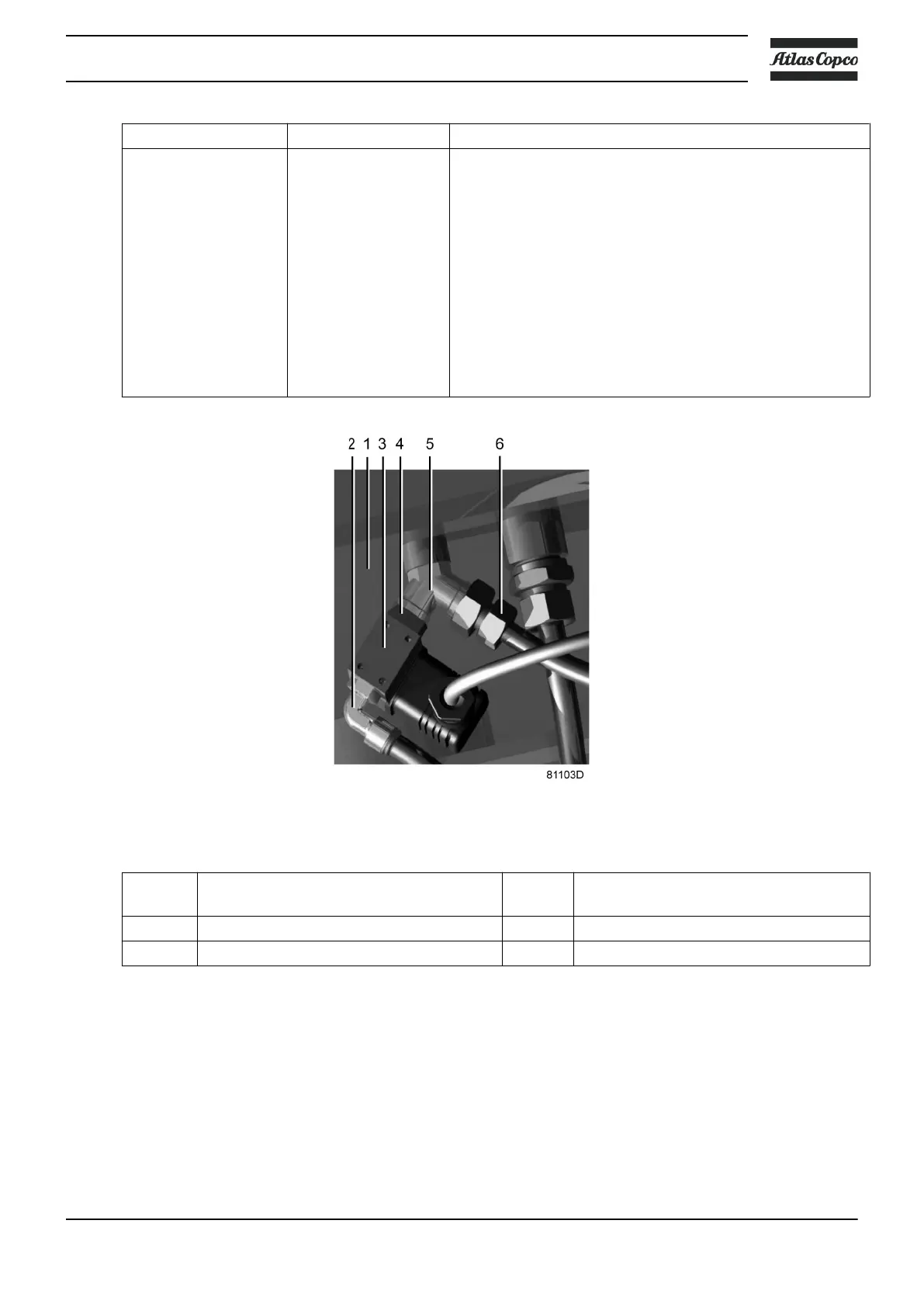

OSCi air injection

1 Aftercooler (WSD in case of a water-

cooled compressor)

4 Strainer

2 Air tube to OSCi vessel 2 5 Y-connection

3 Solenoid valve 6 Air tube to EWD

Automatic as well as manual safety devices to prevent overflow are present. Besides the

automatic overflow switch (7-View of OSCi), which is mounted in a side-chamber on the second

vessel and gives an alarm when condensate level is too high, the customer can check for high

condensate level through the sight glass. On a case-by-case basis, it can be decided to

automatically shut down the compressor in case of an overflow alarm. When overflow occurs, the

resulting waste water must be treated as oil-containing water and must be disposed of according

to local regulations.

Instruction book

2920 7109 51 105

Loading...

Loading...