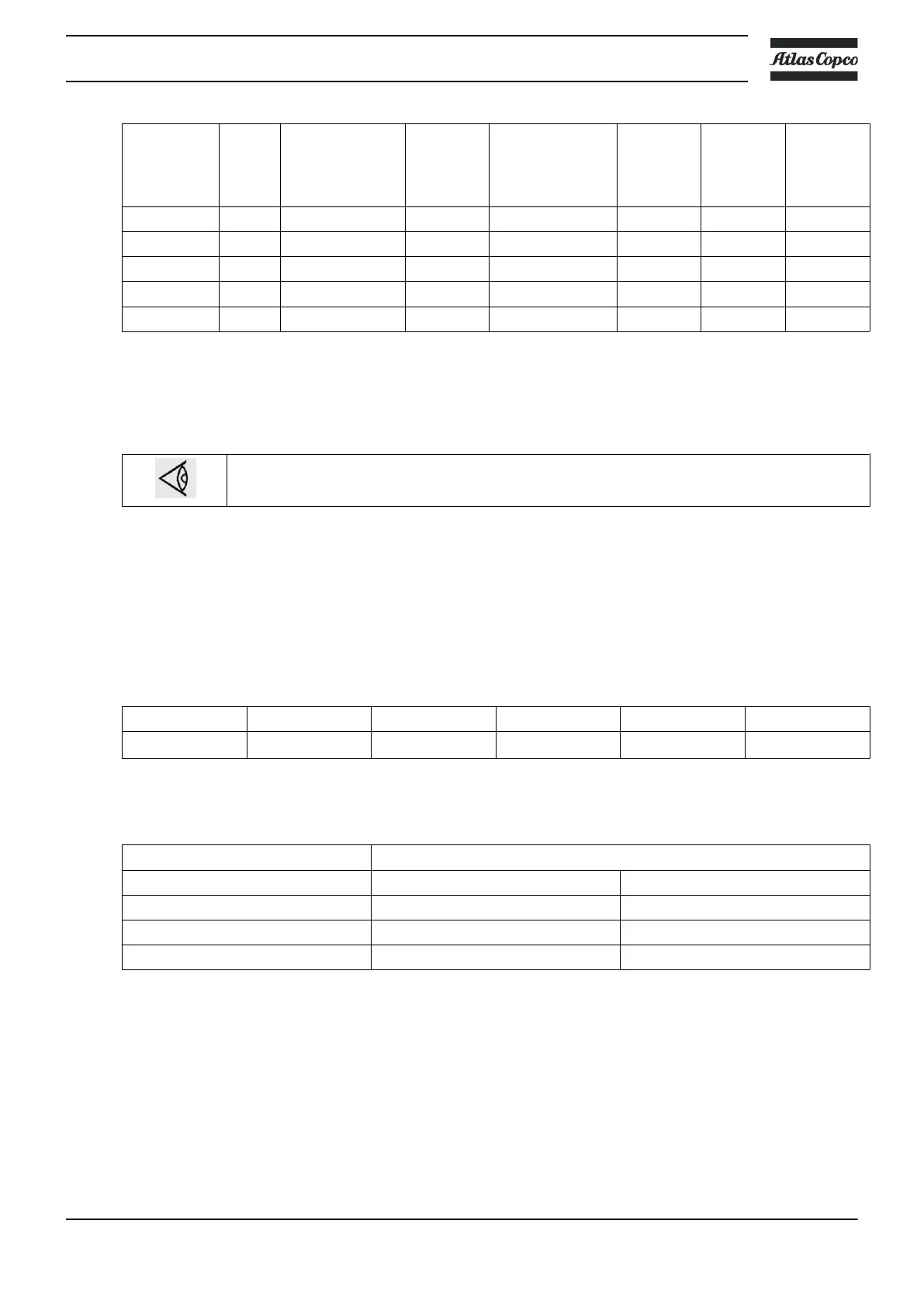

Total

dissolved

solids

(mg/l)

A Temperature

(°C)

B Ca hardness

(ppm CaCO

3

)

C M-

Alkalinity

(ppm

CaCO

3

)

D

86 - 91 0.7 356 - 446 2.2 356 - 446 2.6

92 - 95 0.6 447 - 563 2.3 447 - 563 2.7

564 - 707 2.4 564 - 707 2.8

708 - 892 2.5 708 - 892 2.9

893 - 1000 2.6 893 - 1000 3.0

Interpretation of the values obtained:

• RSI < 6: boiler scale formation

• 6 < RSI < 7: neutral water

• RSI > 7: corrosive water

As a general rule, the RSI index should be between 5.6 and 7.5. If that is not the case,

contact a specialist.

5. Free chlorine (Cl

2

)

Disinfecting with chlorine is not done in closed systems, neither in energy recovery

systems.

A continuous level of 0.5 ppm should not be exceeded. For shock treatments, a maximum

limit of 2 ppm for maximum 30 minutes/day applies.

6.

Chlorides (Cl

-

)

Chloride ions will create pitting corrosion on stainless steel. Their concentration should be

limited, depending from the RSI value.

RSI < 5.5 5.6 < RSI < 6.2 6.3 < RSI < 6.8 6.9 < RSI < 7.5 7.6 < RSI

Cl

-

(ppm)

200 350 500 350 200

For energy recovery systems, the limit is 100 ppm.

7.

Sulphates (SO

4

2-

)

Sulphate (ppm)

Type of cooling system Standard Energy recovery

Single pass < 1000 < 200

Recirculating (with tower) < 1000 not applicable

Closed loop < 400 < 200

8. Iron and Manganese

Instruction book

2920 7109 51 123

Loading...

Loading...