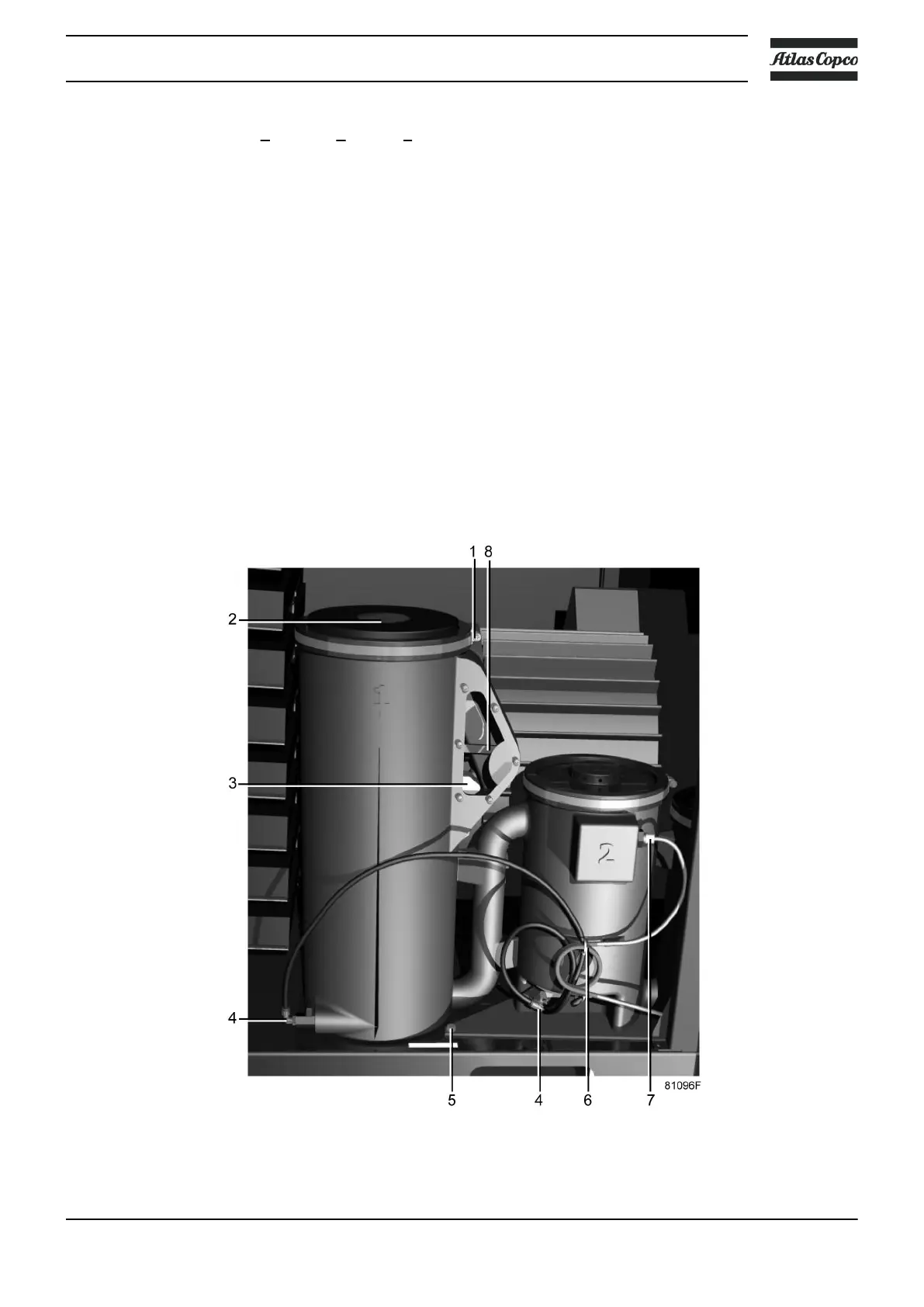

bag (6), filled with oleophilic granular clay (OGC). Through a connection (5) at the bottom of the

second vessel, air is injected into the condensate. This airflow breaks stable emulsions by

enhancing the sorption process of oil onto the OGC. The air supply also prevents the formation of

certain anaerobic bacteria. Also the cover of the second vessel is equipped with ventilation holes

to prevent pressure buildup. The airflow is taken from the aftercooler (on air cooled units) or from

the water separator (WSD) (on water cooled units). An integrated nozzle with strainer limits the

airflow (approximately 450 l/h at reference conditions), while a solenoid valve makes sure no

compressed air is used when the compressor is not delivering air.

The condensate further flows to the third vessel, through a pipe connecting both lower halves of

the vessels. An activated carbon filter (7) cleans the condensate further, and the clean

condensate flows out of connection (9). A test outlet (8) is positioned below the normal outlet.

Both outlets are connected to the compressor drain plate by their corresponding tubes.

At the bottom of the vessels, drain tubes with valves (4) are provided for easy servicing.

In this setup, the cleaning process can be understood by splitting it up per vessel:

• First vessel: pre-separation and sorption of most of the free, directly separable oil

• Second vessel: emulsion separation and oil sorption

• Third vessel: sorption of the remaining oil

View of OSCi

Instruction book

2920 7109 51 93

Loading...

Loading...