2 Expansion Options

Page 10 Mk8 MM Expansion Features Installation and Set-Up Guide 04.09.2016

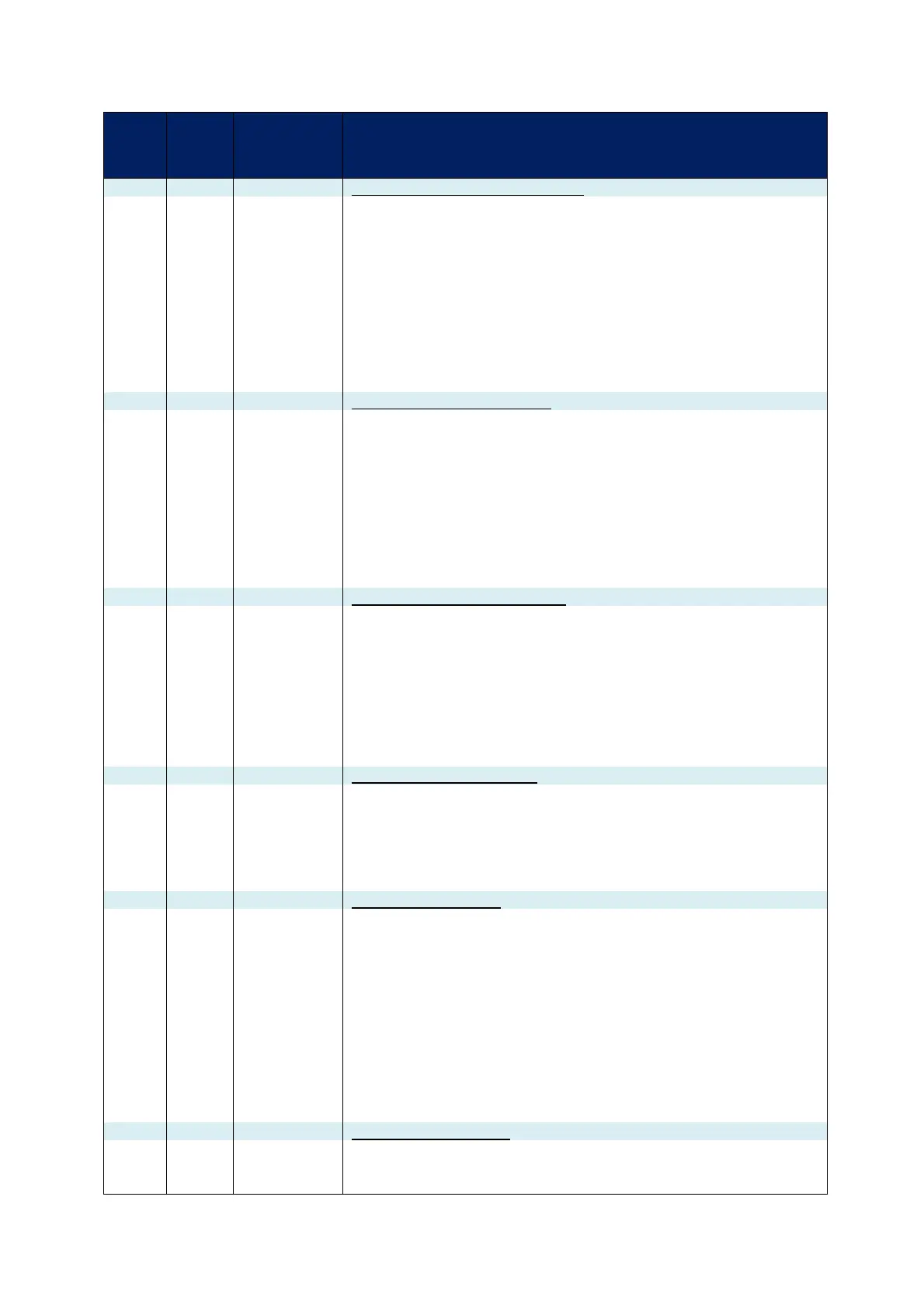

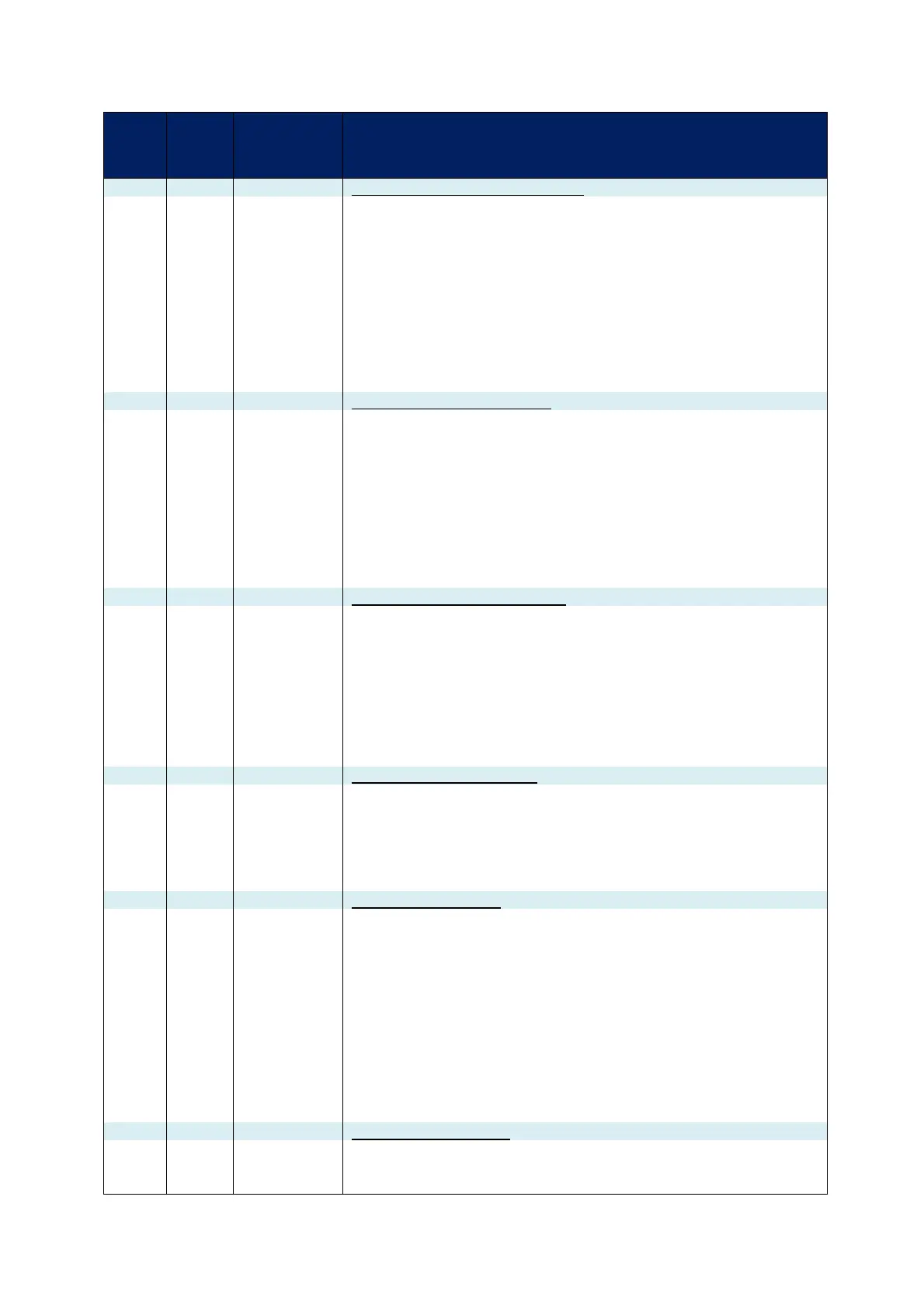

Exp

Option

Default Range Description

13 50 Feedwater Control Proportional Band

The proportional band is set as a percentage between the control point and

first low where the PID control will make corrections to the feedwater going

to the boiler to maintain the control point. The feedwater control will act on

servomotor or VSD depending on how expansion option 2. The control

point represents 0% and first low represents 100%, so it is possible to set

the feedwater control proportional band to a water level below the first

low. If the water level is outside of the proportional band, then the

feedwater servomotor will remain fully open.

0 Disabled

1 – 200 1% - 200%

14 20 Feedwater Control Integral Time

The integral element in the feedwater control will make corrections to the

feedwater via the servomotor or VSD, depending on expansion option 2.

For a slower response, increase the integral time. For a quicker response in

critical steam applications to avoid the water level reaching first low,

decrease the integral time. However if overshoot occurs and the water level

rises to above the control point and this is not desired, then the derivative

element will need to be enabled, see expansion option 15.

0 Disabled

1 – 1000 Seconds

15 0 Feedwater Control Derivative Time

The derivative element in the feedwater control is suitable for applications

requiring a quick response but the water level should not rise too high

above the control point. For example, if the burner is set to stop firing at

high water in expansion option 9 and high water is commissioned not too

far above from control point, then overshoot is undesirable in a critical

steam application, as the burner would stop firing.

0 Disabled

1 – 1000 Seconds

16 900 Feedwater Servo Open Angle

The feedwater servomotor closed position is set by zeroing the

potentiometer in commissioning mode. As default the servomotor is set as

fully open, however this setting can be decreased to shorten the

operational movement range of the servomotor.

100 – 900 10.0

O

– 90.0

O

17 0 Pump Bypass Operation

The pump bypass (terminal TB) will turn on at the switch point set as a % of

the open range of the valve, and will turn off at an offset from the switch

point, set as the bypass hysteresis, see expansion options 18 and 19.

However if the pump is turned off, then the pump bypass will also be turned

off. For setting 1, the pump bypass hysteresis is below the switch point, so

the pump bypass will turn off at an offset below the switch point. For setting

2, the pump bypass hysteresis is above the switch point, so the pump

bypass will turn off at an offset above the switch point.

0 Pump bypass disabled

1 Pump bypass on above switch point

2 Pump bypass on below switch point

18 20 Pump Bypass Switch Point

The bump bypass switch point is set as a percentage of the valve open

range set in expansion option 16.

5 – 95 5% - 95%

Loading...

Loading...