What to do if AUTOFLAME Mk8 MM Controller shows Channel Positioning Error?

- MMark BurnsAug 5, 2025

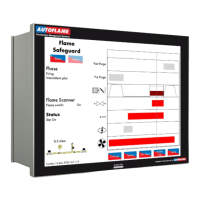

If the AUTOFLAME Controller displays a 'Channel Positioning Error', it could be due to incorrect wiring or an incorrect servomotor position. To resolve this, check the wiring, zero the potentiometer, and ensure the correct voltage is supplied to the servomotors.