10 Water Level Control

Mk8 MM Manual Page | 180

10.5.5 Configuration

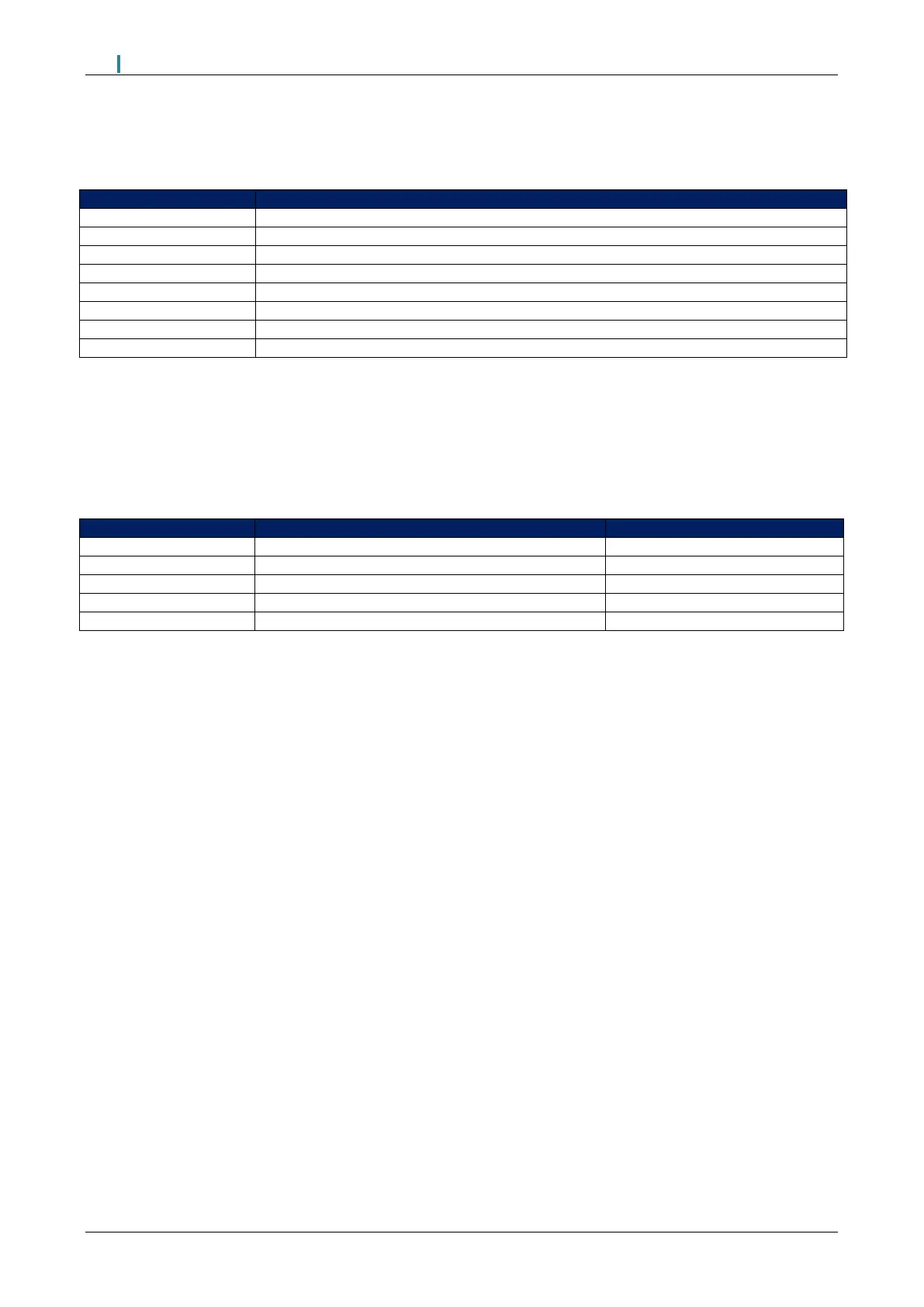

The table below shows the terminals allocated on the MM for the capacitance probes.

+9V supply to capacitance probe 1

0V supply to capacitance probe 1

Digital communications connections from capacitance probe 1

Digital communications connections from capacitance probe 1

+9V supply to capacitance probe 2

0V supply to capacitance probe 2

Digital communications connections from capacitance probe 2

Digital communications connections from capacitance probe 2

When wiring the capacitance probes, the screen is connected through the casing of the lead and through the

probe; therefore, the flying lead should be connected to the MM without a screen. The screen should be

carried through until the connection to the MM; the screen should not be connected to the S terminal.

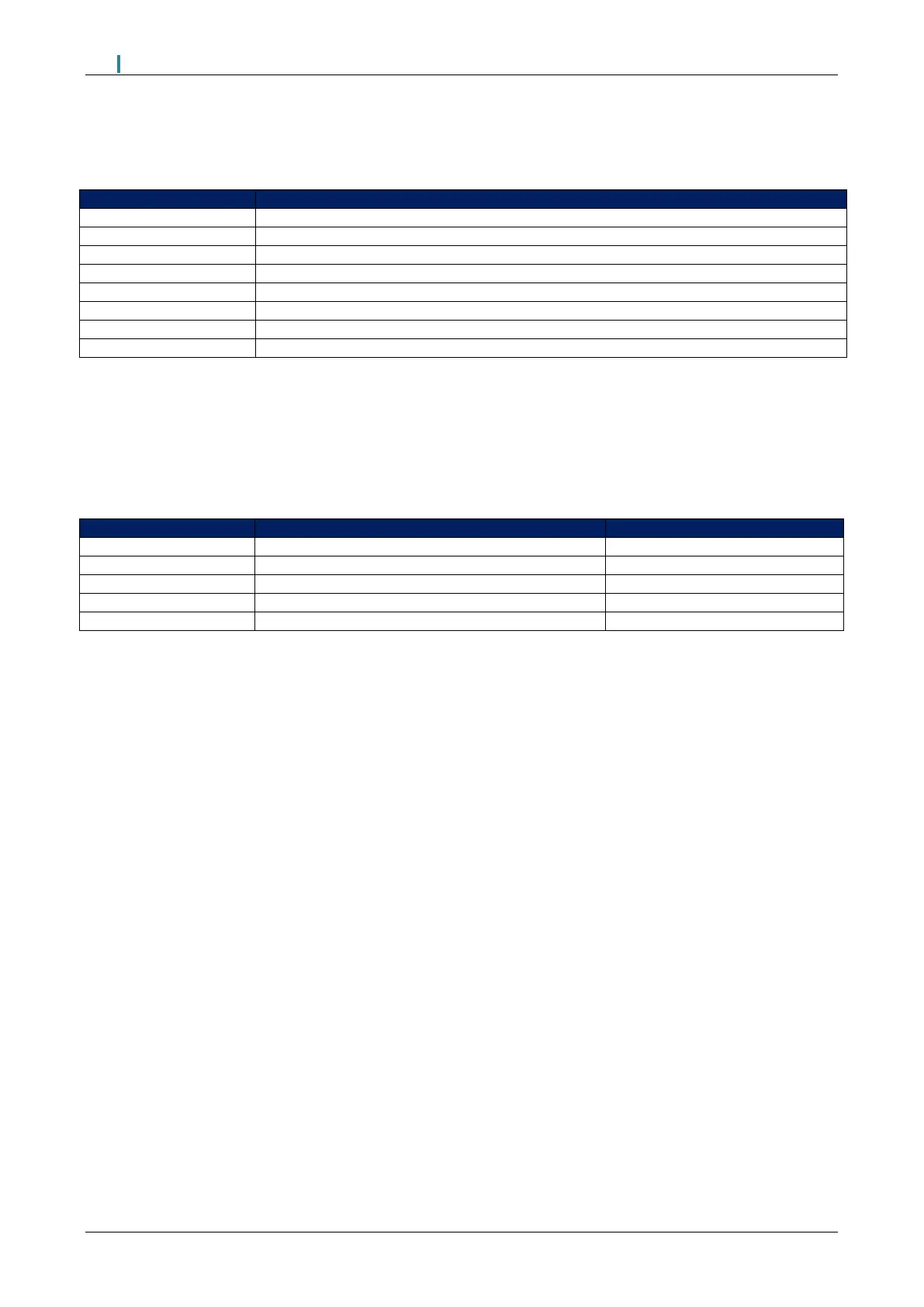

The table below shows the expansion options to be set when using capacitance probes with the MM for

water level detection.

Water level control function

Capacitance probe still water threshold

Capacitance probe filter time

10.5.6 Capacitance Probes Maintenance

When carrying out a boiler service, the capacitance probes must be cleaned and checked for correct and

safe operation. Use nonabrasive cleaning method and a PTFE surface cleaning detergent to clean the

probe. Care must be taken to ensure that the PTFE coating on the surface of the probes is not damaged.

After cleaning the probes, the water levels commissioned for those probes must be checked.

If the probes are mounted directly into the boiler shell it is important to lag the flanges in order to avoid

overheating of the electronics. It is recommended that the probes are not installed too close to the steam off-

take and safety valve connection, but also not too close to the boiler end plates. If possible, they should be

installed near the sight gauge glass.

Loading...

Loading...