13 Draught Control

Mk8 MM Manual Page | 248

13.4 Draught Control Set-Up

13.4.1 Configuration

The draught control servomotor positions, and the stack pressure if using draught control is enabled, is set

during the burner commissioning procedure.

Due to softened error checking, it is recommended to use an industrial UNIC servomotor for the draught

channel; however, a small/large servomotor can be used for smaller applications. The servomotor will need

to be sized according to the torque requirements of the stack damper. If draught control is enabled in

expansion 82, then a Mk8 air pressure sensor is also required, part number MM80005.

For information on installing the draught servomotor and air pressure sensor, please see section 13.1. For

dimensions and technical specification for the draught servomotor, please refer to Autoflame Valves and

Servomotors manual.

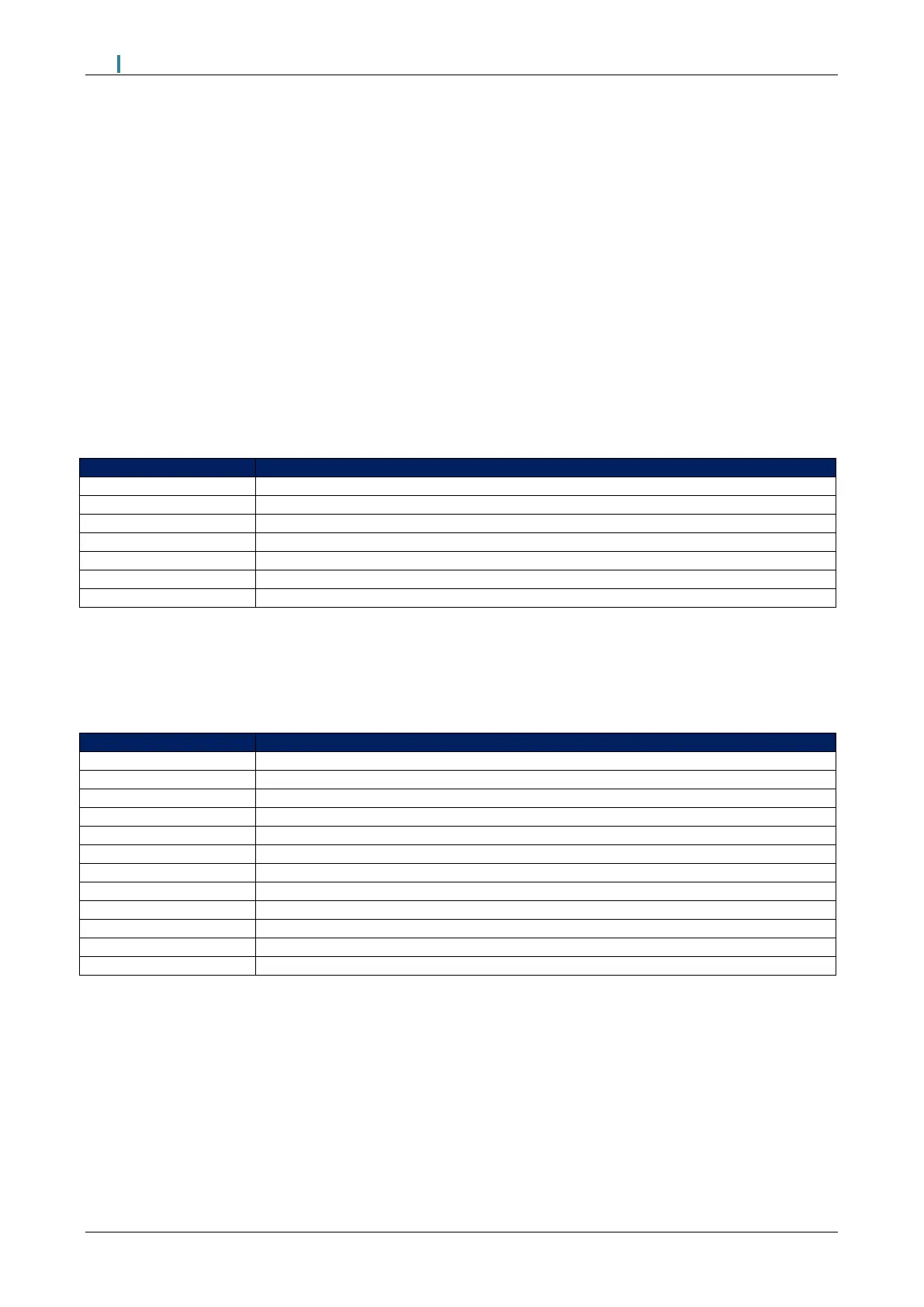

The table below shows the MM terminals for the draught servomotor and Mk8 air pressure sensor.

Digital communication connections from draught control pressure sensor

Digital communication connections from draught control pressure sensor

0V supply to draught control pressure sensor and draught control servomotor

+12V supply to draught control pressure sensor and draught control servomotor

Signal from draught control servomotor, indicating position

Switched neutral – drives draught servomotor clockwise

Switched neutral – drives draught servomotor counter clockwise

When wiring the air pressure sensor, the screen is connected through the casing of the lead and through the

sensor; therefore, the flying lead should be connected to the MM without a screen. The screen should be

carried through until the connection to the MM; the screen should not be connected to the S terminal.

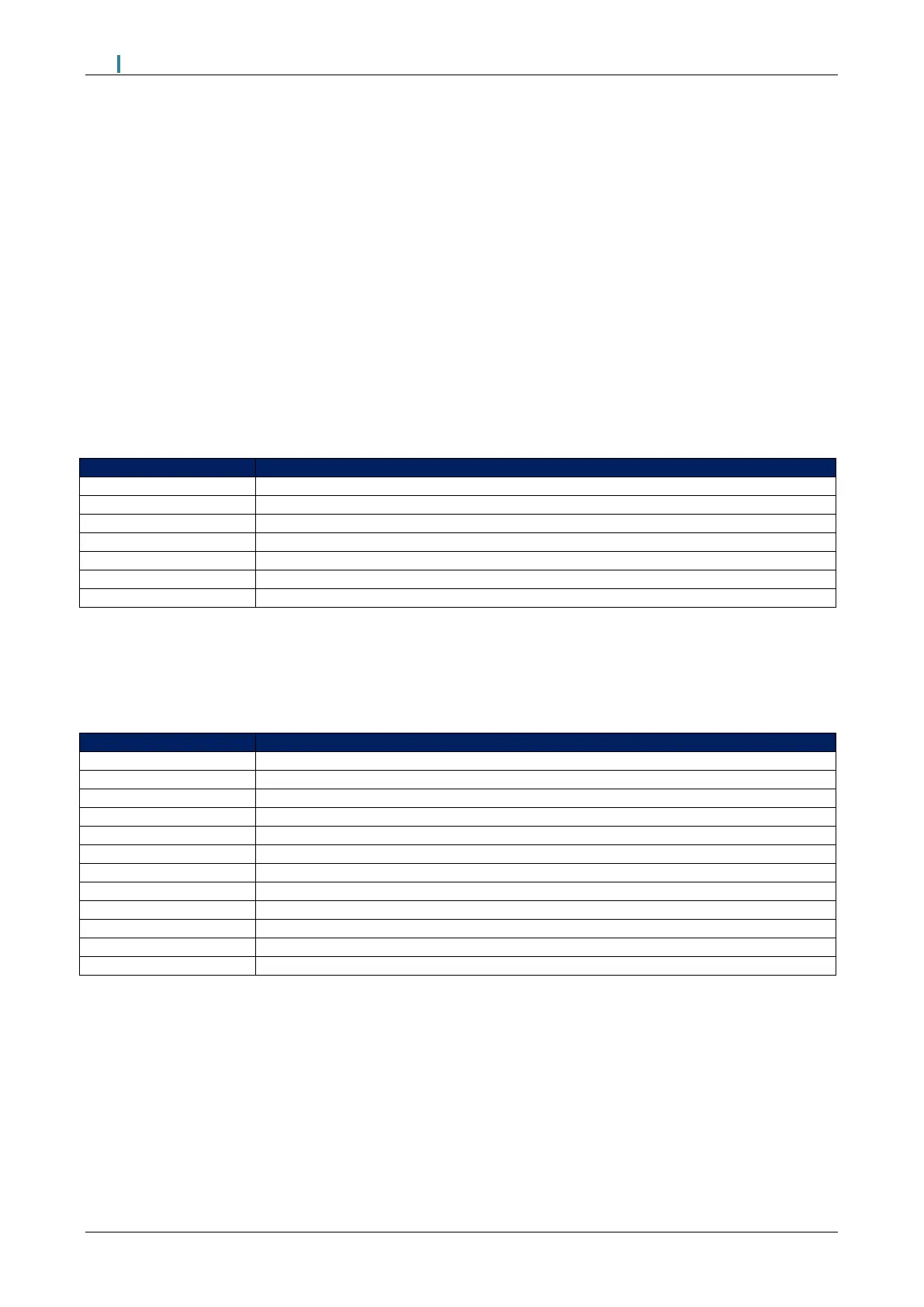

The table below shows the expansions options to be set when using draught control.

Draught control servo channel

Draught servo control method

Draught servo minimum angle

Delay before compensation

Commissioned angle variation tolerance

Pressure tolerance before fault

Action on pressure sensor fault

Pressure sensor filter time

Loading...

Loading...