3 Water Level Control

Page 36 Mk8 MM Expansion Features Installation and Set-Up Guide 04.09.2016

3.4.2 Operation

Capacitance is a measurement of how much a body can store electrical charge. The capacitance is

measured between the surface area of the probe and the surface area of the boiler shell. As the water

level changes the surface area of the boiler shell covered will change, so a change in the capacitance

will be detected. The measured capacitance will increase as the water level in the boiler rises, as the

surface area covered with water will be bigger with more water in the boiler.

The capacitance readings are constantly checked between both of the probes, the commissioned value

and an internal hardware reference capacitor (to account for long term drift and temperature

variations). Both probes control typically “high level”, “required level”, “first low” and “second low”.

The actual water level readings taken from both the probes are constantly compared and checked

against each other, as well the commissioned water levels. When controlling the required level this

data stream is combined with a PI algorithm which controls either the two port feed water control valve

or the variable speed drive to the feed water pump. Each probe is self-checked for electrical and

mechanical integrity by hardware references and self-checking software routines. Each probe and its

control electronics are compensated for ambient temperature variations and component drift,

guaranteeing absolute safety of operation.

By our method the probes control the required level by learning the wave signature and managing the

turbulence within the boiler shell. This “wave signature management” takes into account the changes in

burner firing rate and any variance in pressure in the boiler shell. Incorporated within the system

hardware are all necessary electronic switching functions to control audible alarms, mute/reset and

indication lights required to meet standard North American and European codes. Safety, accuracy and

integrity are guaranteed.

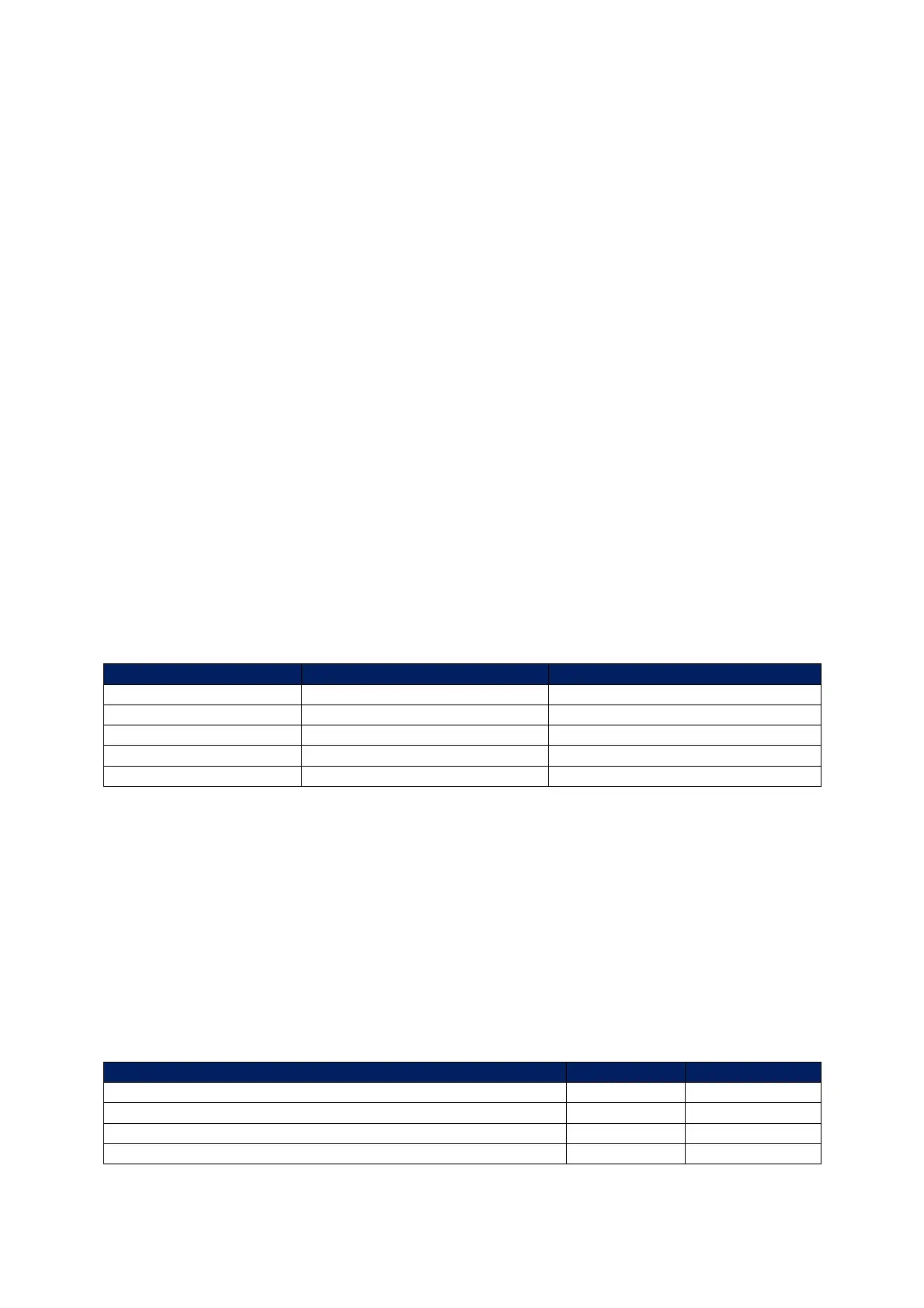

3.4.3 Specification

Part No. Length (Metric) Length (Imperial)

WLCP500 500mm 20”

WLCP750 750mm 30”

WLCP1000 1000mm 40”

WLCP1250 1250mm 50”

WLCP1500 1500mm 60”

Additional capacitance probe lengths are available upon request.

All capacitance probes are supplied with 2m (6ft) flying lead.

Probe connection: ½” (13mm) – quick connect

Stainless steel probe

PTFE coated

IP 68 rating

Temperature rating of housing: 0 - 70°C (32 - 158°F) - ambient temperature of air around the boiler

Note: The probes must not be cut. If the probes are cut this will act as a short between the positive

and negative plates of the capacitor and will stop the probes from working.

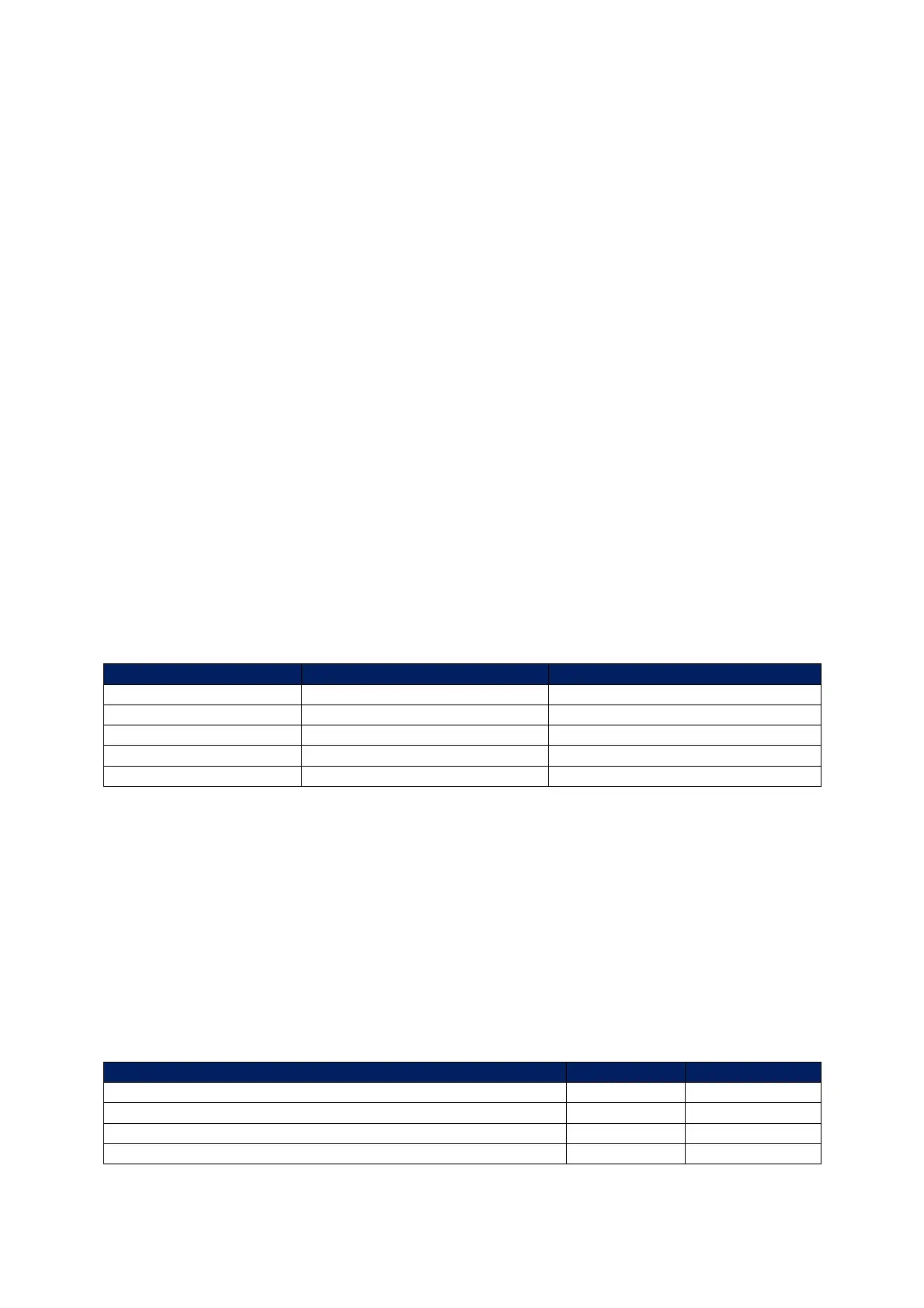

The following table illustrates the pressure tests on the probes:

Test Metric Imperial

Nominal Size of Line 15mm ½”

Maximum Allowable Pressure 27 Bar 392 PSI

Maximum Allowable Temperature 230

P

C 446

O

F

Test Pressure 60 Bar 870 PSI

Loading...

Loading...