3 Water Level Control

Page 26 Mk8 MM Expansion Features Installation and Set-Up Guide 04.09.2016

3.1.3 Water Treatment

Water is a solvent, and its natural form will contain impurities that can have an unwanted effect on the

boiler operation by either corroding the metal heat transfer surfaces, or by lowering the rate of heat

transfer from the surfaces to the water. The impurities which are found in water include:

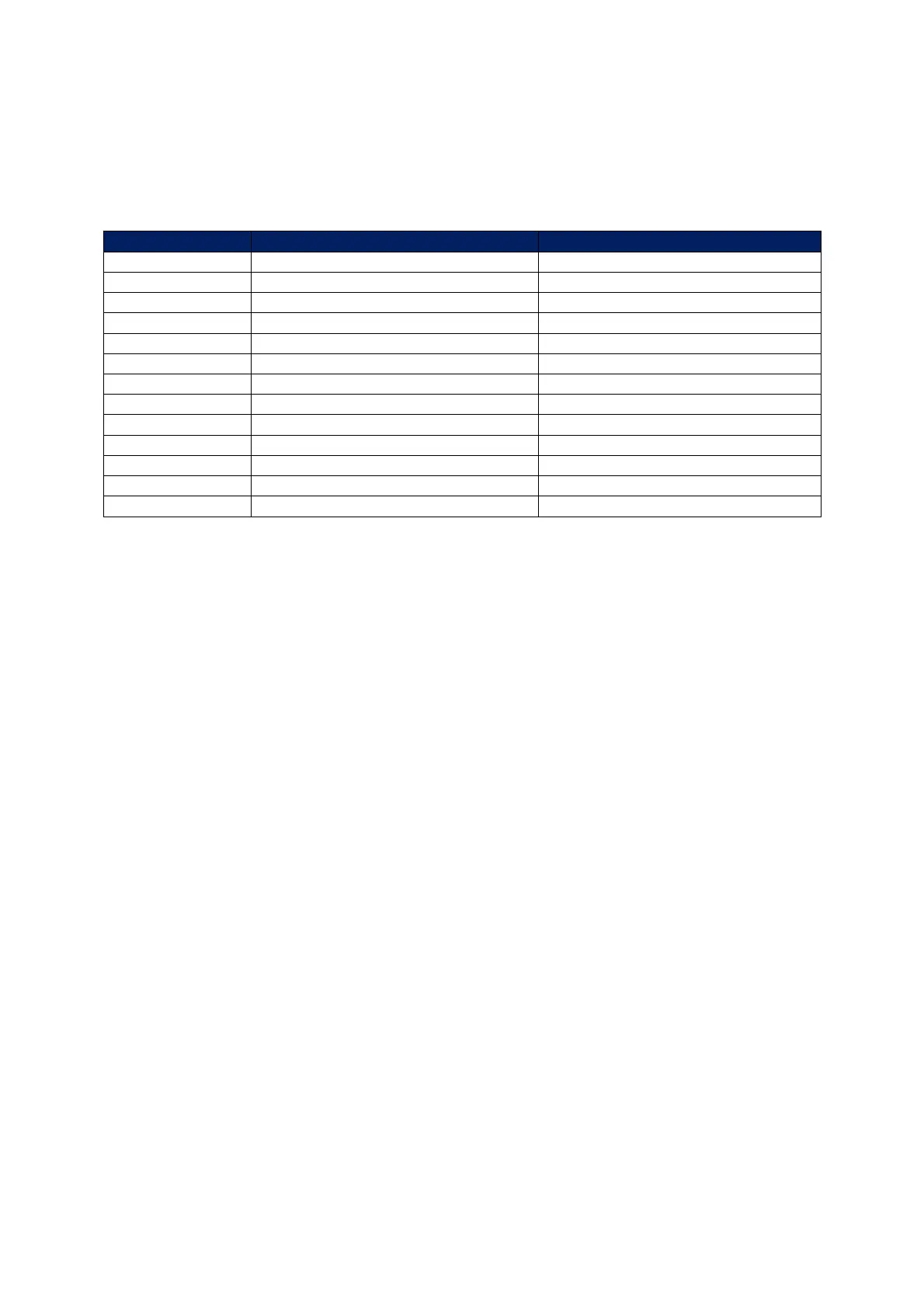

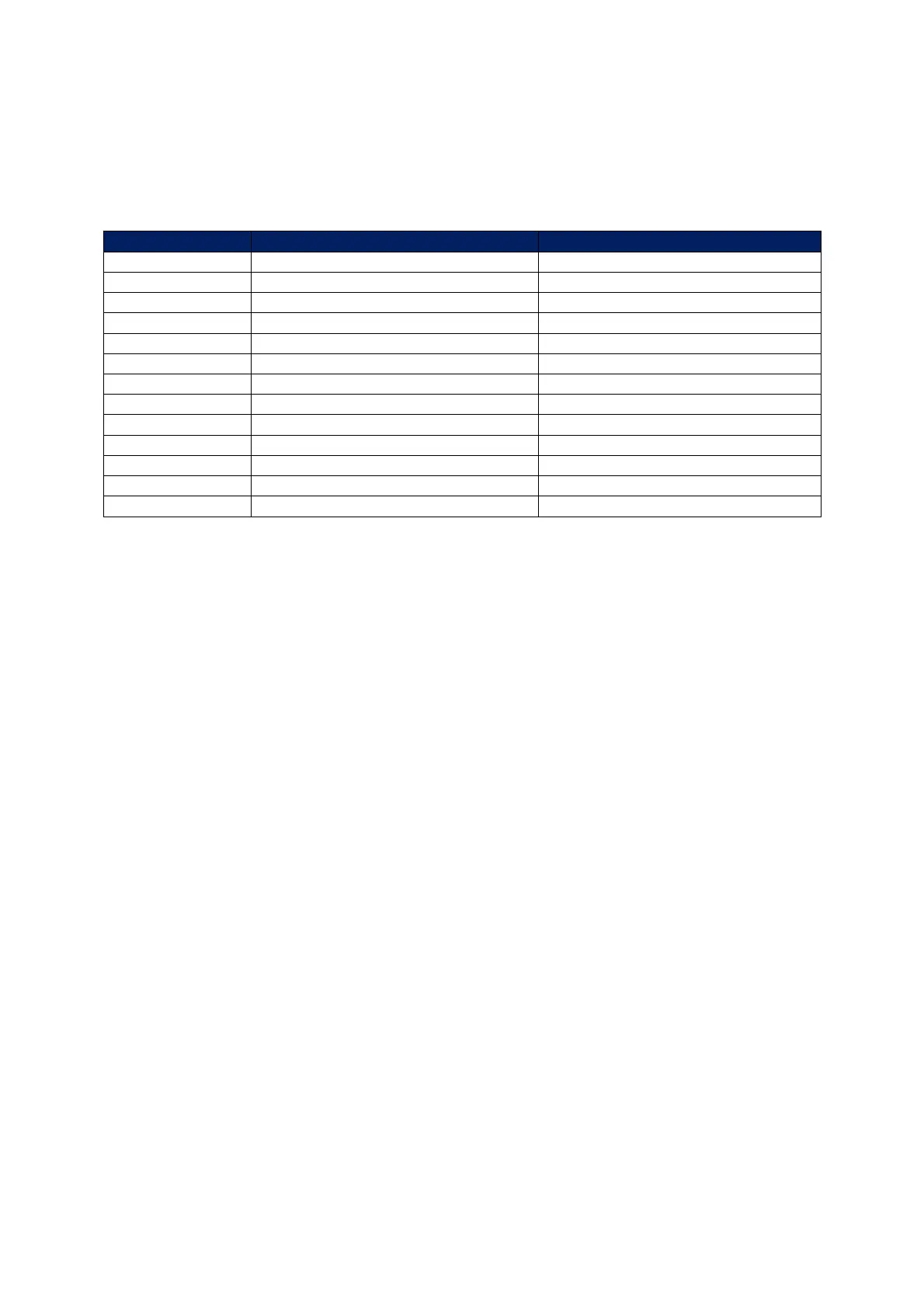

Symbol Name Effect

CaCO3 Calcium carbonate Soft scale

Ca(HCO3)2 Calcium bicarbonate Soft scale + CO2

CaSO4 Calcium sulphate Hard scale

CaCl2 Calcium chloride Corrosion

MgCO3 Magnesium carbonate Soft scale

MgSO4 Magnesium sulphate Corrosion

Mg(HCO3)2 Magnesium bicarbonate Scale, corrosion

NaCl Sodium chloride Electrolysis

Na2CO3 Sodium carbonate Alkalinity

NaHCO3 Sodium bicarbonate Priming, foaming

NaOH Sodium hydroxide Alkalinity, embrittlement

Na2SO4 Sodium sulphate Alkalinity

SiO2 Silicon dioxide Hard scale

The water treatment regime in any boiler installation has an effect on the life of the boiler. It is

important to install any level controls in accordance with the local and national authorities’ boiler

inspection bodies, approval authorities and boiler manufacturer’s guidelines. As well as this, it is vitally

important to select a suitable water level treatment regime to ensure correct and safe operation of the

Autoflame system. Water treatment companies should be able to assist with the selection and

implementation of a suitable water treatment regime.

It is important to remember that the guidelines set are limits that should not be exceeded at any time. If

these guidelines and limits are not maintained then this can cause adverse effects on equipment

installed as well reducing the longevity of the boiler and increasing ongoing maintenance

requirements.

Total dissolved solids (TDS) are impurities which have not been boiled off with the steam. If the TDS

becomes more and more concentrated in the water, bubbles and foaming will occur at the water

surface. If these solids then leave with the steam from the boiler, they can contaminate the steam plant

equipment, such as heat exchangers, steam traps and control valves. The boiler manufacturer will

specify the required TDS level in the water for that boiler. The Mk8 MM has an expansion feature

which allows the system to control the TDS level in the boiler via top blowdown control, please see

section 4 for top blowdown control.

Suspended solids will exist in the water and if the boiler water is disturbed, they will remain in this

state, however when the water is still, these solids will descend to the bottom. Over time, these solids

will build up and reduce the heat transfer, and may result in the boiler running less efficient. To reduce

this sludge which will build up at the bottom of the boiler, the Mk8 MM has a bottom blowdown

control expansion feature. Please see section 5 for bottom blowdown control.

Note: It is the responsibility of the boiler operator to ensure that the water has been

treated and maintained according to the boiler manufacturer’s specifications.

Loading...

Loading...