5 Bottom Blowdown

Page 88 Mk8 MM Expansion Features Installation and Set-Up Guide 04.09.2016

5.3 Installation Guidance

The bottom blowdown valve must be sized appropriately for blowdown rate required, which will be

affected by the boiler pressure, size of blowdown line and blowdown line length from the boiler to the

bottom blowdown vessel. The blowdown rate that is required for that boiler will vary according to the

operating conditions, contaminants in the feed water and boiler design.

The bottom blowdown valve must be installed along the blowdown pipeline according

to local code and regulations. It is the responsibility of the factory trained technician or

engineer to configure the bottom blowdown timings according to the specifications

given by the boiler manufacturer.

In multi-boiler systems where a bottom blowdown valve is fitted to each boiler, enabling Autoflame

sequencing in option 16 will ensure that only boiler in that loop blows down at a given time. If a

blowdown time is set the same on all the MMs in a sequencing loop, the MM with the lowest ID

complete its blowdown first, followed by the rest of the MMs, sequentially. If Autoflame sequencing is

not used for multi-boiler system requiring bottom blowdown in the UK, then valves must be interlocked;

this ensures that only boiler can be blown down at one time. Please see local code and regulation on

bottom blowdown in multi-boiler systems.

The Autoflame bottom blowdown module (part number BBC70004) has a built in lithium ion battery,

so should a power failure to the module, bottom blowdown fault or MM error occur, the battery will

drive the servomotor to the closed position. The servomotor is powered by 24V DC from the bottom

blowdown module.

5.3.1 Bottom Blowdown Valve

Water valves are universal for feed water, TDS, and bottom blowdown function. ½” and ¾” water

level valves must be used with large servomotors. Industrial unic 05 servomotors must be used 1” and

1 ½”, and industrial unic 10 for 2” water valves. for water valves bigger than ¾”.

Maximum operating pressure: 29 Bar (425 PSI)

Maximum operating temperature: 235

O

C (455

O

F)

Please see section 3.2.1 for more information on water valves.

Note: Please Valves and Servomotors manual for water level valve dimensions, drawings and

information on service and maintenance.

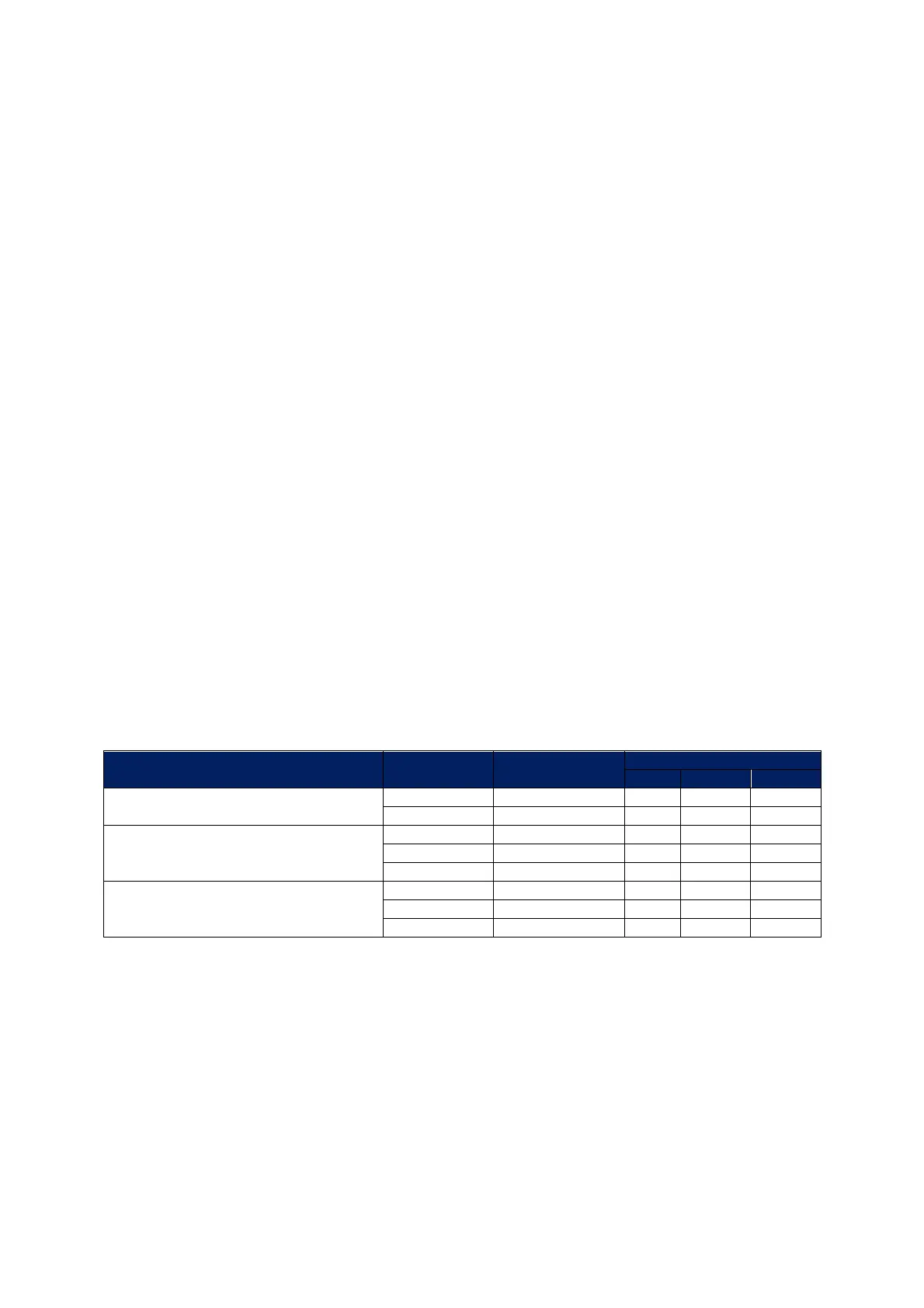

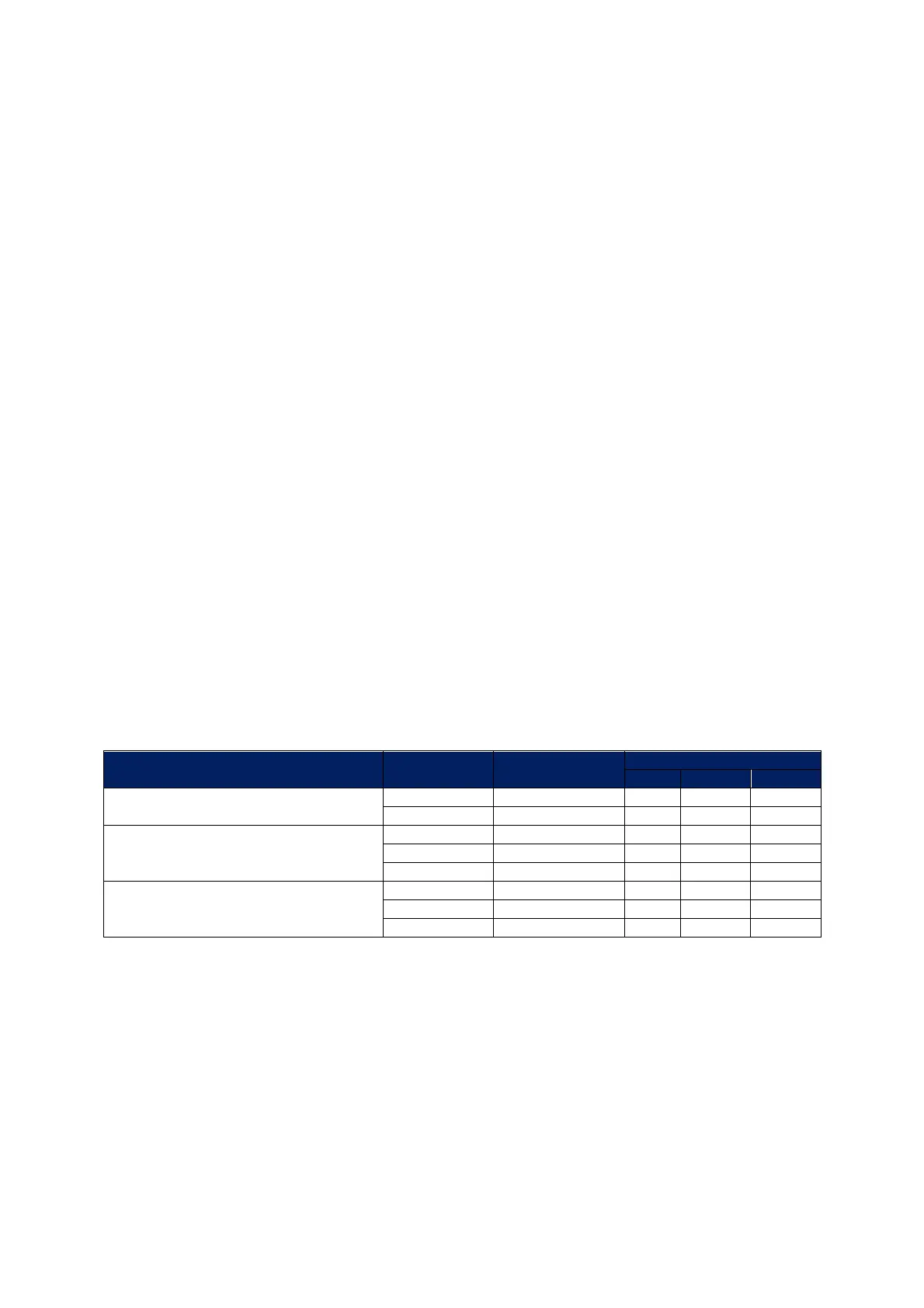

Valve Type Size Part No.

Servomotor

Large Unic 05 Unic 10

Threaded BSP/ NPT

15mm (½”) WLCVO15 •

20mm (¾”) WLCVO20 •

Flanged PN40

25mm (1”) WLCVO25/FL •

40mm (1 ½”) WLCVO40/FL •

50mm (2”) WLCVO50/FL •

Flanged ANSI 300lb

25mm (1”) WLCVO25/FLU •

40mm (1 ½”) WLCVO40/FLU •

50mm (2”) WLCVO50/FLU •

Loading...

Loading...